Air suction counting dividing device for paperboard stacking machine

A stacker, single-device technology, applied in the directions of transportation and packaging, sending objects, and thin material handling, can solve the problems of inaccurate counting, difficult to control lifting of cardboard, inaccurate counting of separate orders, etc., and achieve accurate counting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

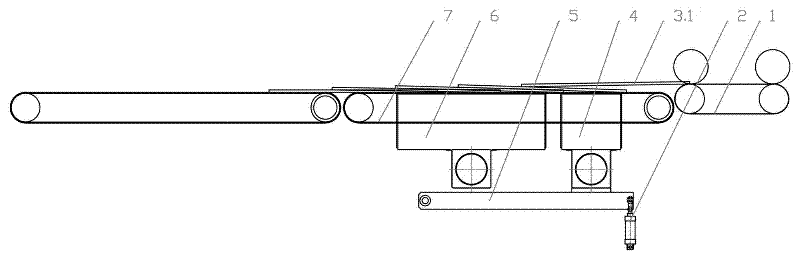

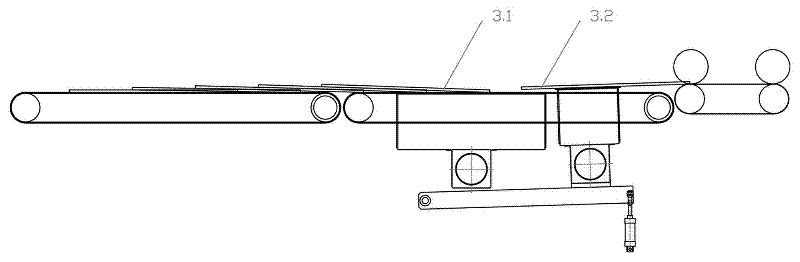

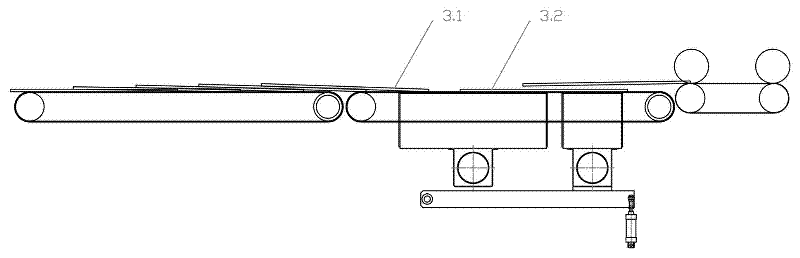

[0013] Figure 1 to Figure 3 It is a schematic diagram of each working state structure of the suction counting and sorting device of the cardboard stacker. It can be seen from the figure that the suction, counting and sorting device of the cardboard stacker includes the delivery conveyor belt 1 of the cross-cutting machine, the conveyor belt 7 of the stacker and its control The device is characterized in that: the fixed suction box 6 and the movable suction box 4 placed under the conveyor belt 7 of the stacker are fixedly connected with the lifting frame 5, and the end of the lifting frame 5 at one end of the movable suction box 4 is placed Connected with cylinder 2 piston.

[0014] The piston of the cylinder 2 accepts the counting instruction for each cardboard issued by the front section cross-cutting machine, so that the suction port of the movable suction box 4 rises and falls with the expansion and contraction of the piston of the cylinder 2, or is higher than the stacker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com