Vertical prestressed anchorage system and construction method thereof

A technology of vertical prestressing and prestressing tendons, applied in bridge parts, erecting/assembling bridges, bridges, etc., can solve problems such as rusting or damage of prestressing tendons, long exposure time of prestressing tendons, cumbersome and complicated construction, etc. Achieve the effect of simple construction, avoiding corrosion and damage, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

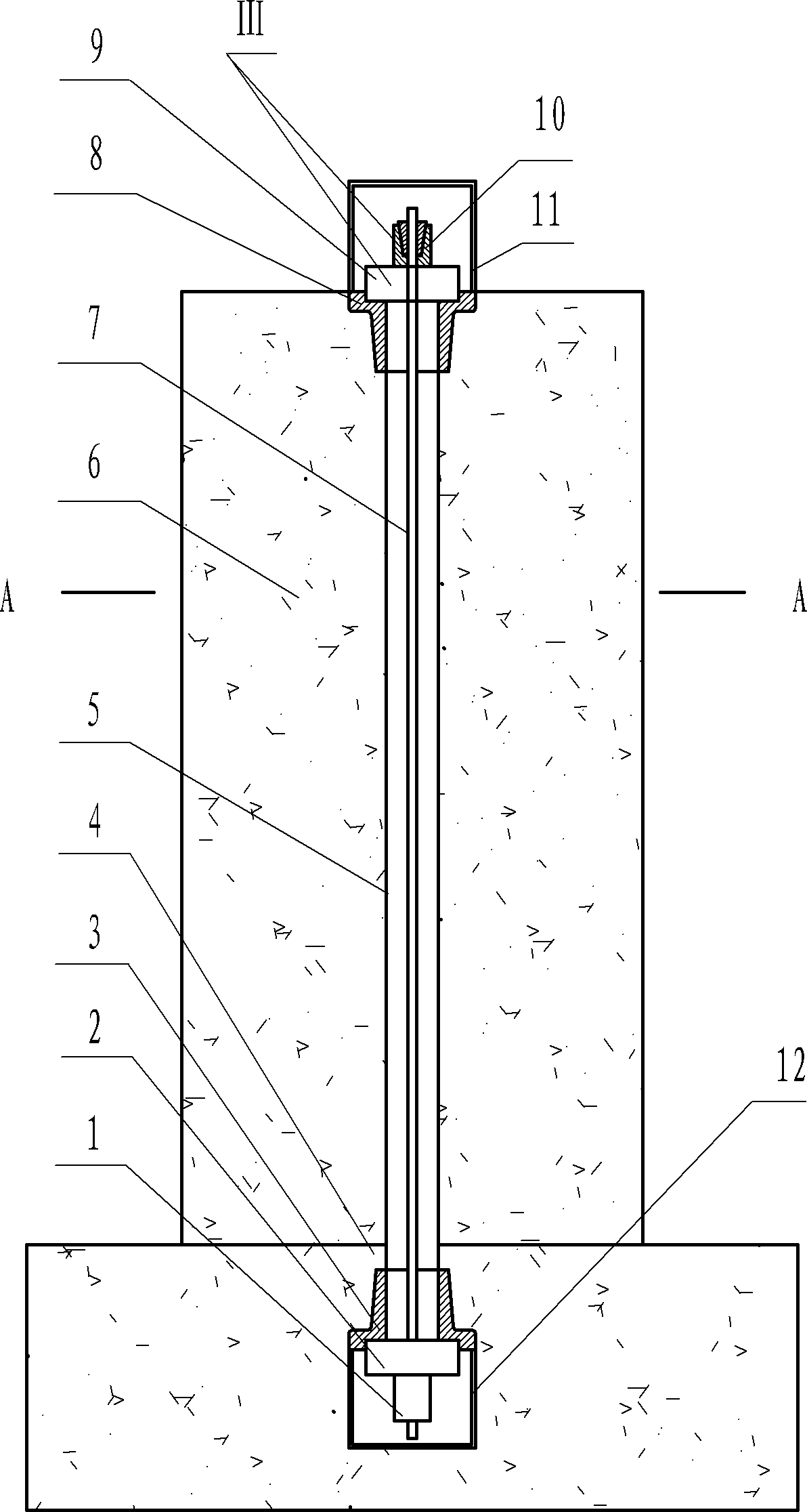

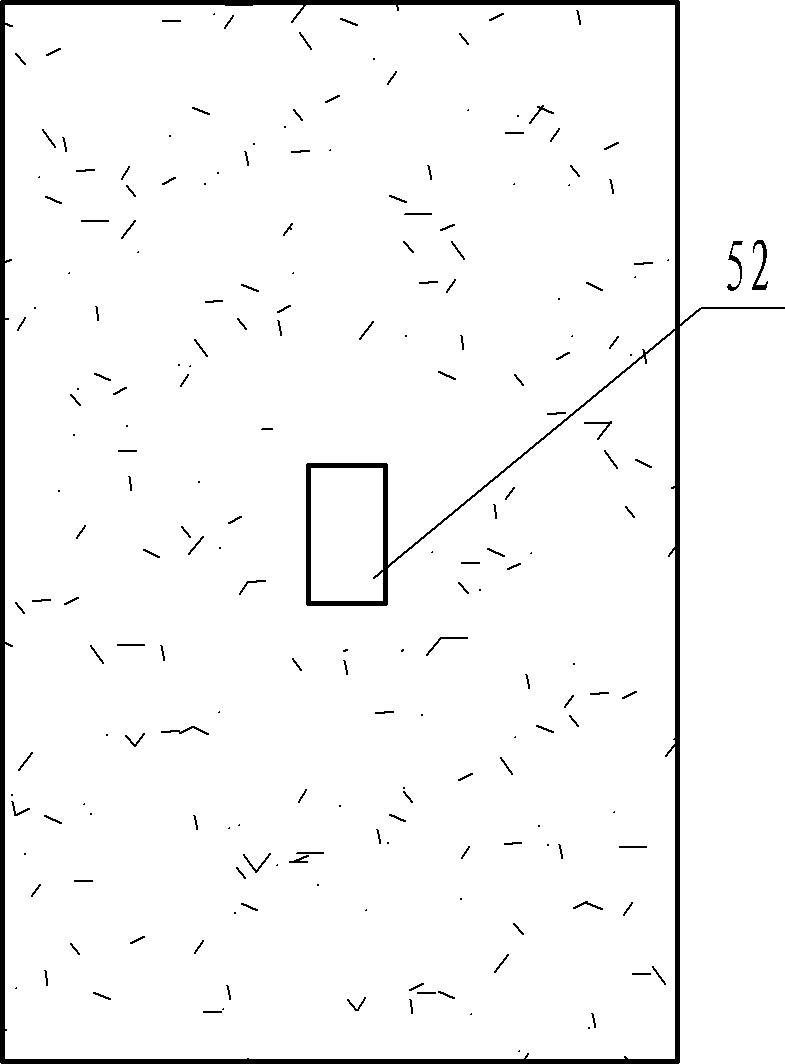

[0051] A vertical prestressed anchor system, including embedded parts I, lower anchor unit II and upper anchor unit III, such as Picture 1-1 , figure 2 As shown, the embedded part I includes an upper anchor pad 8, a pre-embedded pipe 5, a lower anchor pad 3 and a grouting cap 12; 2. After the extruded sleeve 1 is anchored, it is formed as a whole with the anchor plate 2 at the fixed end. The anchor plate 2 at the fixed end is a rectangular parallelepiped anchor plate (see image 3 ); the upper anchor unit III is composed of a tension end anchor plate 9 placed on the upper anchor pad 8 for anchoring the other end of the prestressed tendon 7 and an upper anchor 10, and the tension end anchor plate 9 is also Anchor plate with rectangular parallelepiped shape (see Figure 1);

[0052] The through holes on the upper anchor backing plate 8 and the lower anchor backing plate 3 are rectangular, and its size is based on the lower anchor unit. The end faces of the upper anchor backing...

Embodiment 2

[0058] A construction method of a vertical prestressed anchorage system, the steps comprising:

[0059] A. Installation of embedded parts Ⅰ:

[0060] ① Cooperate and connect the lower anchor plate 3 with the grout cover 12 to form a whole (see Figure 5-1 ), located in the anchorage area at the bottom of the prestressed tendon, and pre-embedded in the cap 4; a grouting port is left under the grouting cover 12 to lead out the grouting pipe so that the grouting is sealed after the tensioning is completed;

[0061] ② Install or make embedded pipeline 5:

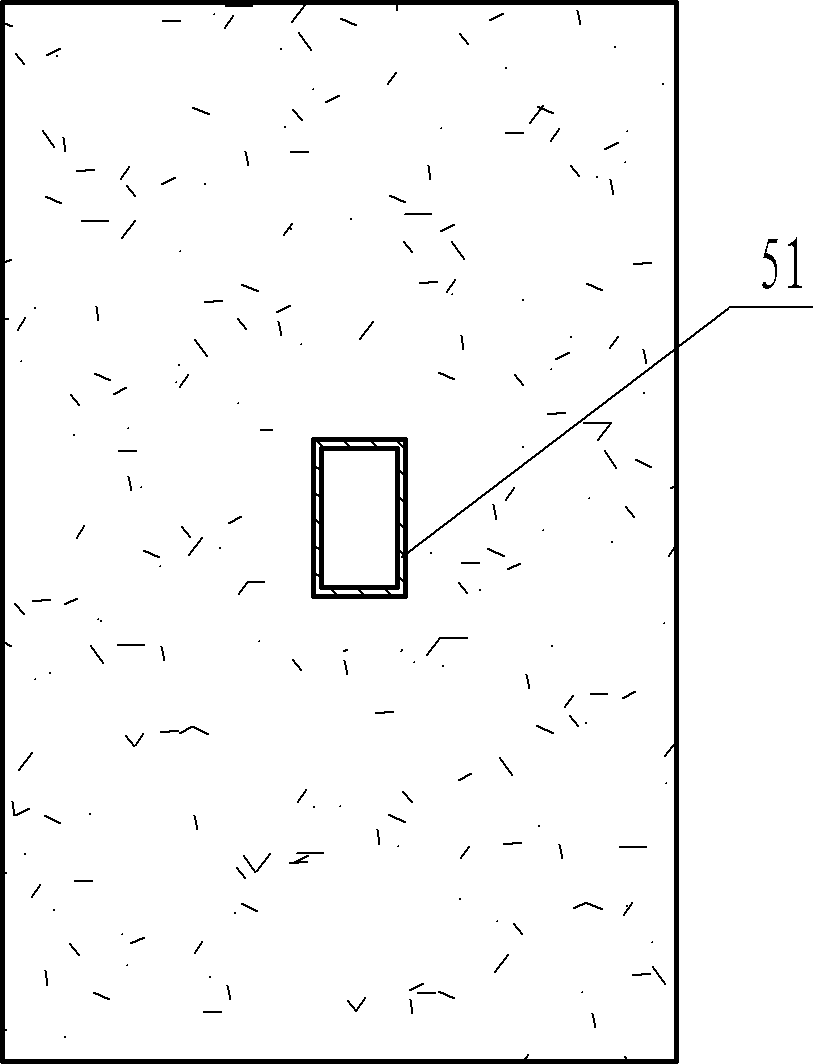

[0062] If described pre-buried pipeline 5 is made of pre-buried pipe 51 (referring to Figure 1-2 , figure 2 ), the construction technology of segmental welding and concrete layer pouring is adopted; as the pier body 6 is continuously poured and the height is increased, the pre-embedded pipe 51 will also be increased in length by welding; finally, the anchor pad 8 is pre-buried to complete the pier body pouring;

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com