Span-division erection construction method of construction catwalk of multi-tower suspension bridge

A construction method and technology for suspension bridges, which are applied in the directions of suspension bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low construction efficiency and inability to meet the construction requirements of erection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

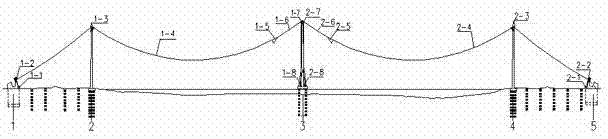

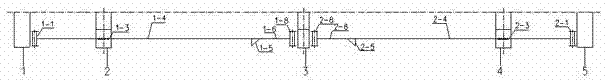

[0030] The catwalk construction method of the multi-tower suspension bridge is to divide the multi-span construction catwalk into spans, and every two spans are divided into a construction section, and each construction section is equipped with a corresponding single-line reciprocating traction system, such as figure 1 , figure 2 As shown, the present embodiment is a three-tower suspension bridge, the construction catwalk is a four-span catwalk, and two sets of single-line reciprocating traction systems are set with the second cable tower 3 as a boundary, and each single-line reciprocating traction system independently erects catwalk load-bearing cables, and finally After the section erection is completed, the load-bearing cables of the catwalk are fixed at the section.

[0031] Because the present invention is a set of independent traction system to undertake the erection of a construction catwalk in one section, the sequential operation of erecting the catwalk is multi-poin...

Embodiment 2

[0033] Such as image 3 , 4 , 5, wherein one set of single-line reciprocating traction system in the above embodiment is composed of the first traction system hoist 1-1, the first traction cable guide wheel 1-2, the first tower top traction cable guide wheel group 1-3 1. The first traction cable 1-4, the first puller 1-5, the second traction cable 1-6, the second traction cable guide wheel 1-7, and the second traction system winch 1-8.

[0034] The first traction system winch 1-1 and the first traction cable guide wheel 1-2 are fixed at the first anchorage 1, and the first tower top traction cable guide wheel set 1-3 is fixed at the top of the first cable tower 2 , the tower top of the second cable tower 3 is fixed with a second traction cable guide wheel 1-7, and the tower bottom of the second cable tower 3 is fixed with a second traction system hoist 1-8; the first traction system hoist 1-1 The first traction cable 1-4 is connected to the first puller 1-5 through the first...

Embodiment 3

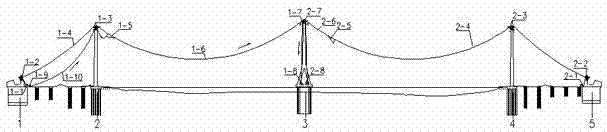

[0040] Such as Figure 6 , 7 , 8, in the two sets of single-wire reciprocating traction systems of embodiment 1, another set of single-wire reciprocating traction systems matched with embodiment 2 is composed of the third traction system hoist 2-1, the third traction cable guide wheel 2-2 , the second tower top traction cable guide wheel group 2-3, the third traction cable 2-4, the second puller 2-5, the fourth traction cable 2-6, the fourth traction cable guide wheel 2-7, the The four traction system consists of 2-8 hoists.

[0041] The third traction system hoist 2-1 and the third traction cable guide wheel 2-2 are fixed at the second anchorage 5, and the second tower top traction cable guide wheel group 2-3 is fixed at the top of the third cable tower 4 , the tower top of the second cable tower 3 is fixed with the fourth traction cable guide wheel 2-7, the tower bottom of the second cable tower 3 is fixed with the fourth traction system hoist 2-8; the third traction syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com