Involute tooth plate adjustable two-way crusher

An adjustable crusher technology, applied in grain processing, etc., can solve problems such as broad spectrum of technical parameters, unsatisfactory environmental protection and energy saving, difficulty in installation and replacement of wearing parts, and unsatisfactory crushing effect, etc., to achieve easy maintenance, Reasonable structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

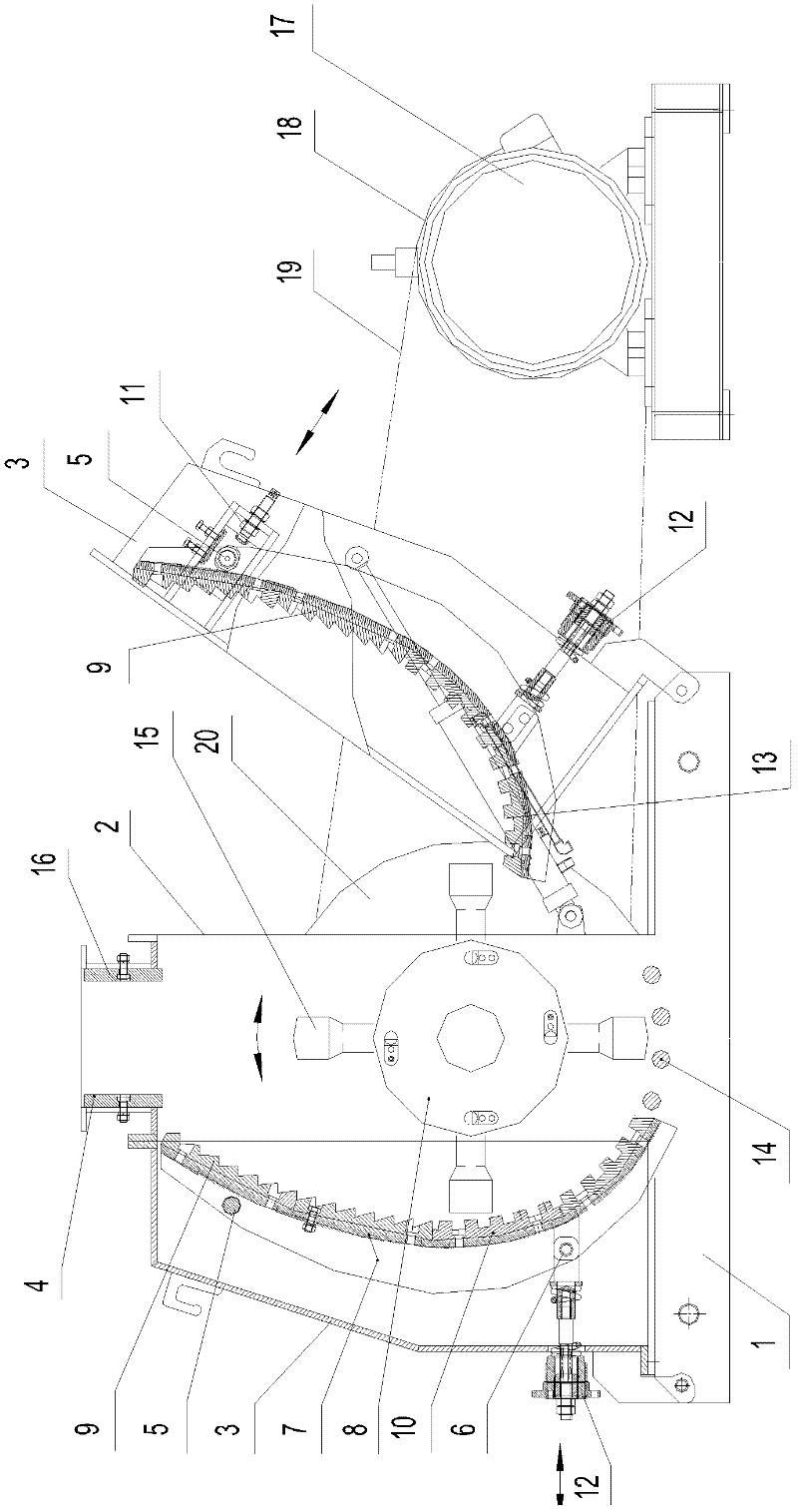

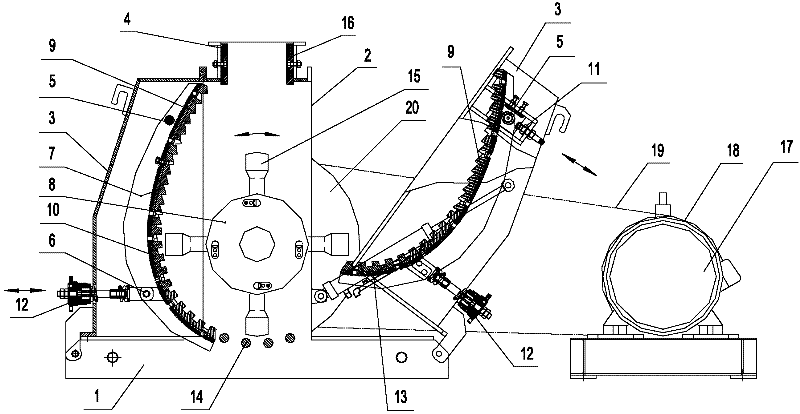

[0011] Attached below figure 1 An embodiment of the present invention is described.

[0012] Two-way crusher with adjustable involute tooth plate, including a base 1 and a motor 17. The middle part of the base 1 is provided with a middle box 2. Both sides of the base 1 are symmetrically hinged with a side box 3 and the side box 3 connects the middle box. Surrounded by 2, the uppermost end of the middle box 2 is provided with a feeding inlet adjustment assembly 4, the inner wall of the feeding inlet adjustment assembly 4 is provided with a lining plate 16, and the middle box 2 is provided with a rotor assembly 8. Four groups of hammerheads 15 are evenly distributed on the circumference of the rotor assembly 8. The bottom of the middle box 2 is provided with a screen bottom 14 for the crushed materials to pass through. The upper end of the tooth pallet 7 passes through the pin shaft 5 and the lower end Connected to the side box 3 by a hinge 6, the upper part of the tooth plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com