Automatic case producing unit for precision casting robot

A technology of precision casting and robotics, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of production rate and work efficiency, human health hazards, unstable product quality, etc., to reduce costs and reduce production costs. Requirements for manual operation level, the effect of improving production rate and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

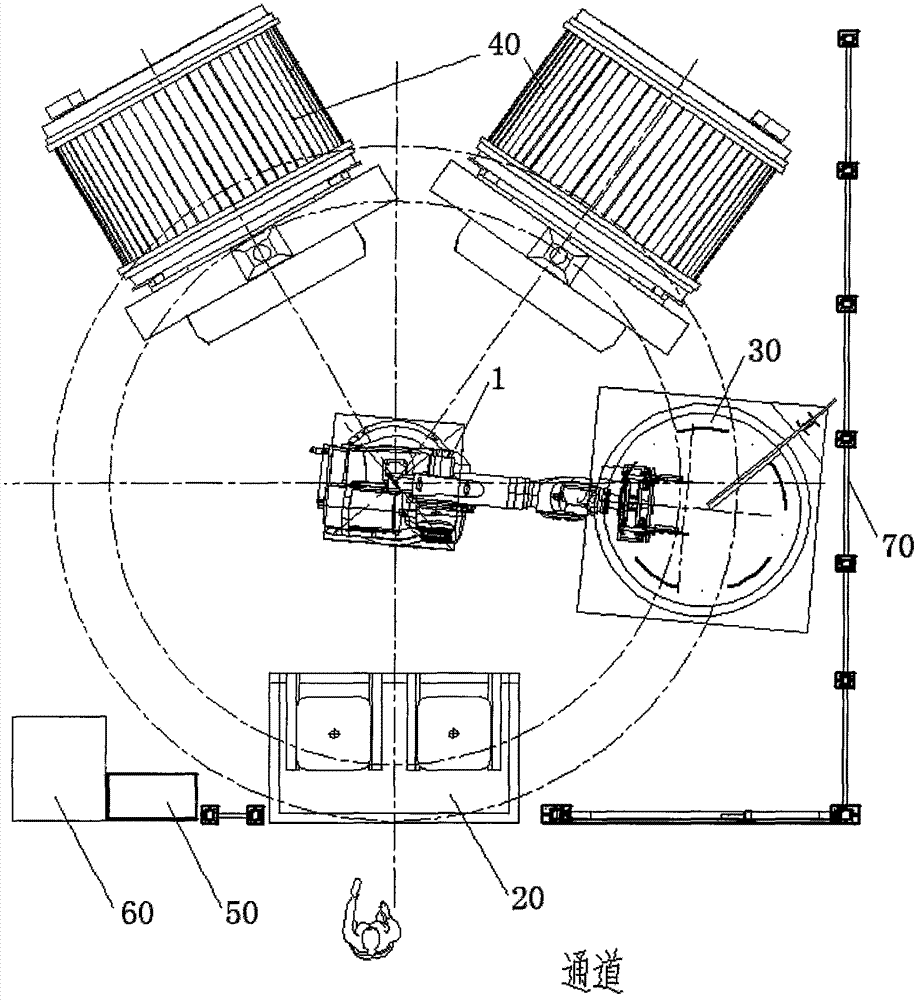

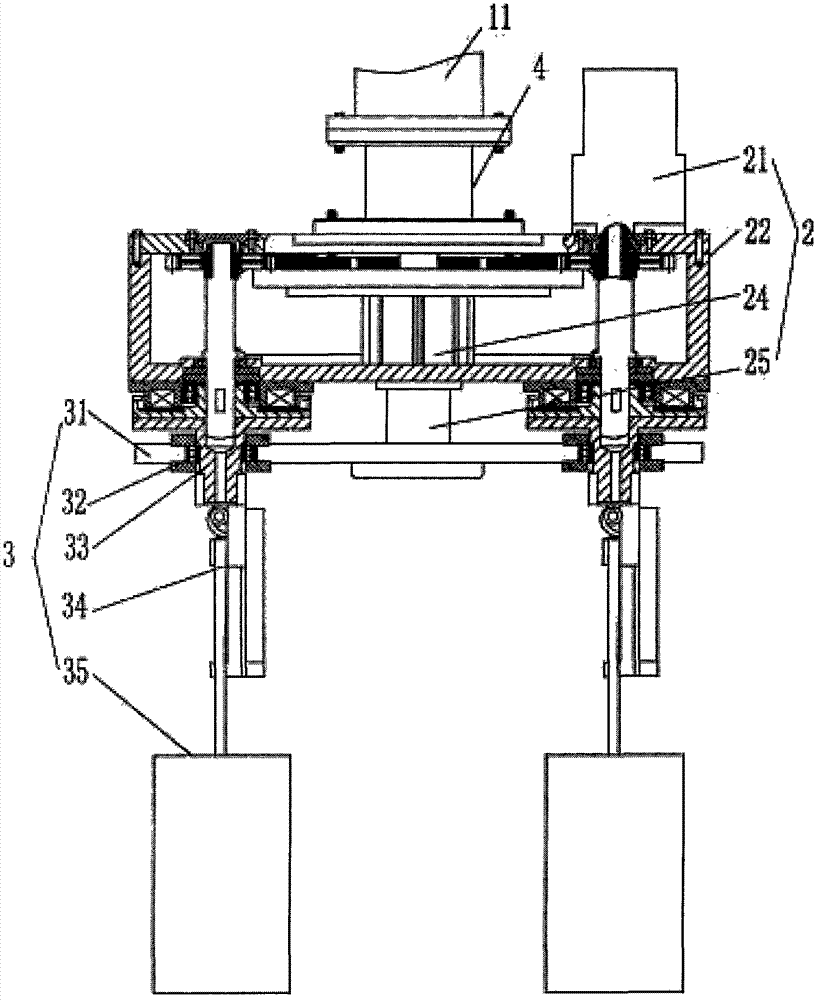

[0023] Example: see Figure 1 to Figure 5 As shown, the automatic shell-making unit of the investment casting robot includes a six-degree-of-freedom robot 1, a slurry dipping machine 30 and a sand shower 40, and a sand shower 40 and a slurry dipping machine 30 are placed around the six-degree-of-freedom robot 1;

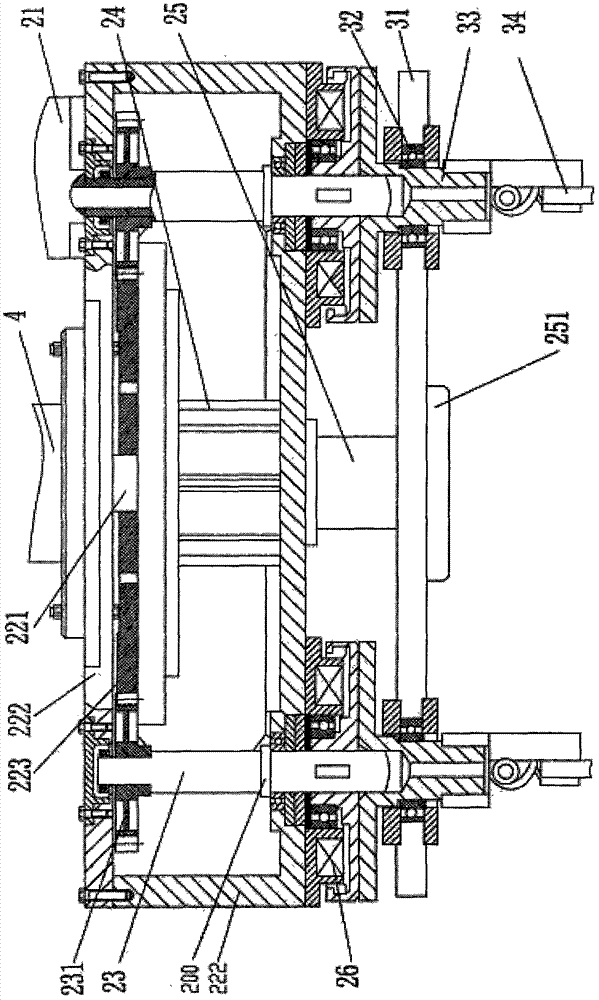

[0024] The structure of the upper clamp 2 is that the motor 21 drives the rotating shaft 23 of the gear box 22 to rotate, and the cylinder 24 is fixed in the gear box 22, and the piston rod 25 of the cylinder 24 extends out of the gear box 22, and the piston rod 25 is fixedly connected with a pressure block 251, The rotating shaft 23 is fixedly connected with an electromagnet 26 on the protruding part outside the gear box 22;

[0025] The structure of the lower fixture 3 is that a bearing 32 is fixed on the mechanism frame 31, a magnetic rotating shaft 33 is fixed on the bearing 32, a hanging object shaft 34 is inserted into a sleeve and fixed on the magnetic rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com