Special sand box for high-efficiency V method casting

A special sand box and sand box technology, which is applied in the direction of casting molding equipment, mold boxes, manufacturing tools, etc., can solve the problems of affecting the quality of castings, uneven casting density, uneven negative pressure of sand boxes, etc., to achieve simple structure and solve The effect of uneven negative pressure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

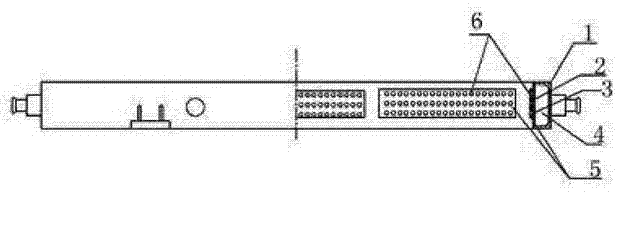

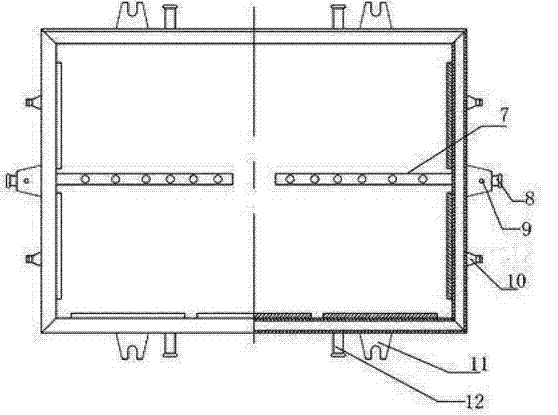

[0013] Such as figure 1 , 2 As shown, the present invention provides a special sand box for V-method casting, which includes a sand box inner wall 2 and a sand box outer wall 1, a negative pressure chamber 4 is formed between the two sand box walls, and the sand box inner wall 2 is provided with a suction hole 6 and the filter screen 3 installed on the air extraction hole for filtering sand, the filter screen 3 is covered on the air extraction hole 6, a crossbeam 7 is arranged on the inside of the sand box, and a mesh is arranged on the crossbeam 7, which can be used to extract Gas; the filter screen 3 is pressed on the inner wall 2 of the sand box with the screen press plate 5, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap