Dragging cushion for bogie frame of locomotive

A locomotive bogie and connecting plate technology, which is applied in traction devices, railway car body parts, transportation and packaging, etc., can solve the problems of poor vibration isolation performance and elastic reset ability, insufficient bonding strength of metal parts and rubber materials, and mutual separation. Problems, to achieve the effect of improving the axial tangent stiffness and elastic reset ability, good linear stability and curve passing ability, and ensuring the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

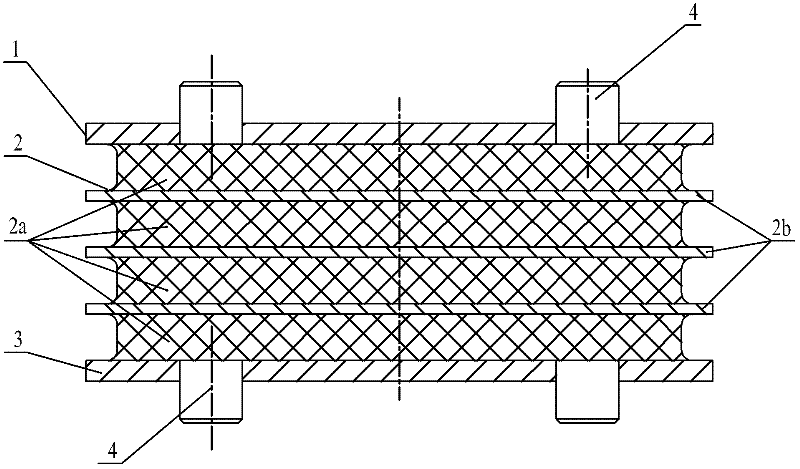

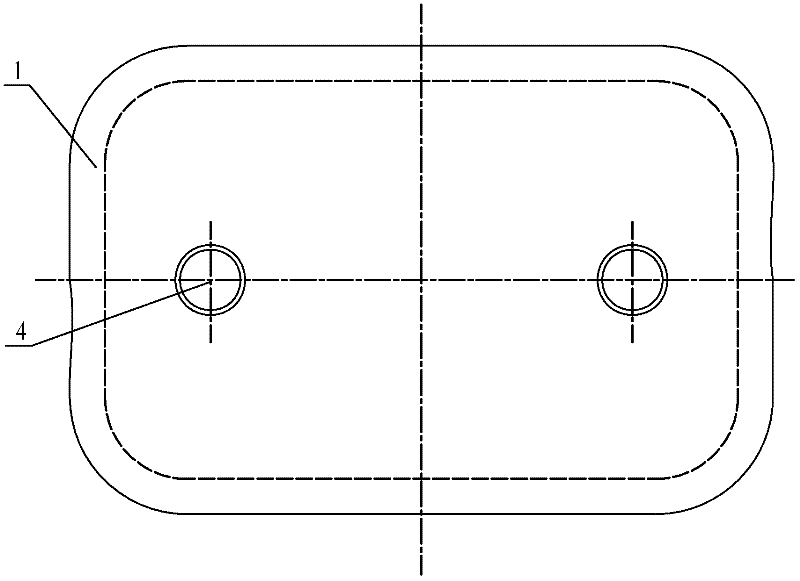

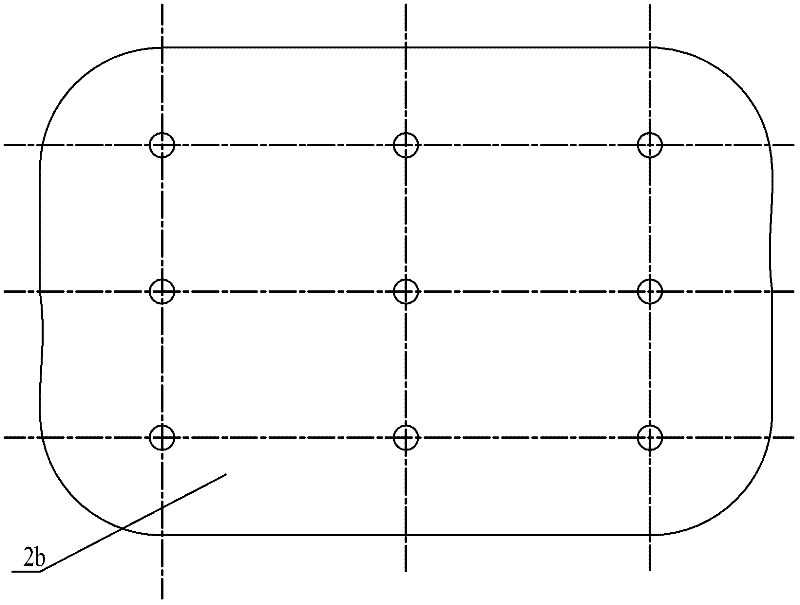

[0016] like figure 1 , figure 2 As shown, the locomotive bogie traction pad of the present invention is mainly composed of an upper connecting plate 1, a lower connecting plate 3 and a rubber composite layer 2. The upper connecting plate 1, the lower connecting plate 3 and the rubber composite layer 2 are rectangular structures with rounded corners. , the upper connecting plate 1 and the lower connecting plate 3 are fixed with positioning pins 4 respectively, and the rubber composite layer 2 is arranged between the upper connecting plate 1 and the lower connecting plate 3 and is combined and fixed with them; the rubber composite layer 2 is composed of four One rubber layer 2a and three partitions 2b are formed, and four rubber layers 2a and three partitions 2b are arranged at intervals and fixed with each other.

[0017] In the present invention, the ratio of the thickness of the rubber layer 2a to the separator 2b is set to be 4:1-5:1. The thickness ratio is designed reaso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com