Method for preparing two-dimensional nano molybdenum disulfide by jet cavitation technology

A molybdenum disulfide, two-dimensional nanotechnology, which is applied in the field of preparation devices of two-dimensional nano-molybdenum disulfide, can solve the limitation of preparation method, the quality of two-dimensional nano-molybdenum disulfide is not perfect, and it cannot meet the requirements of mass production of two-dimensional nano-molybdenum disulfide. Molybdenum and other problems, to achieve the effect of low production cost and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

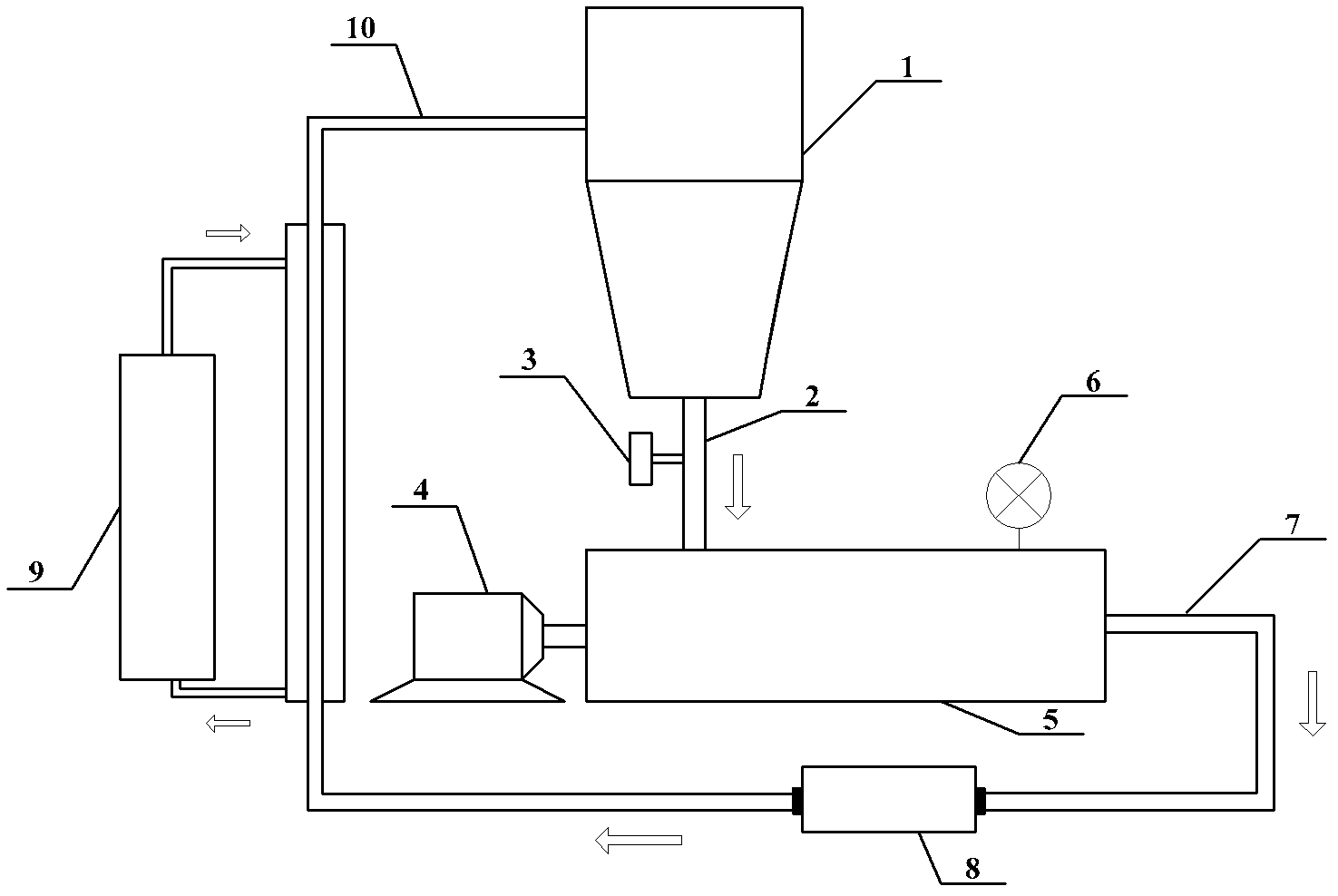

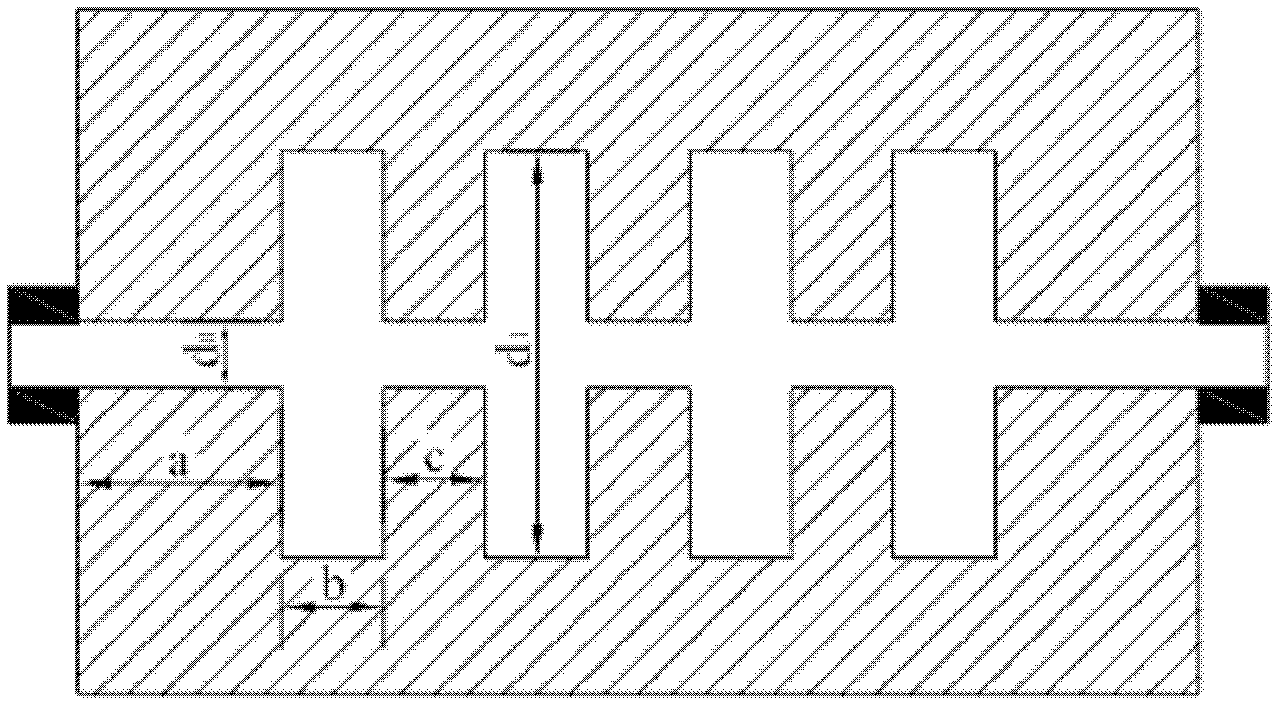

[0068] A jet cavitation device such as figure 1 As shown, the cavitation generator as figure 2 As shown, the process for preparing two-dimensional nanomolybdenum disulfide by jet cavitation method is:

[0069] Step 1: Prepare molybdenum disulfide aqueous solution with good dispersion stability by preparing 1.9% molybdenum disulfide powder with an average particle size of 12 μm, 0.1% sodium carboxymethyl cellulose modifier (CMC) and 98% water. Into the storage tank 1;

[0070] The second step: set the working pressure of the plunger pump 5 to 20Mpa, open the valve 3 at the water inlet pipe 2, the molybdenum disulfide aqueous solution enters the plunger pump 5 from the storage tank 1, start the motor 4 system operation, and the molybdenum disulfide aqueous solution is Pressurize to a specified pressure of 20Mpa; the power of the motor 4 is 30KW;

[0071] The third step: the pressurized molybdenum disulfide aqueous solution enters the cavitation generator 8 through the high-p...

Embodiment 2

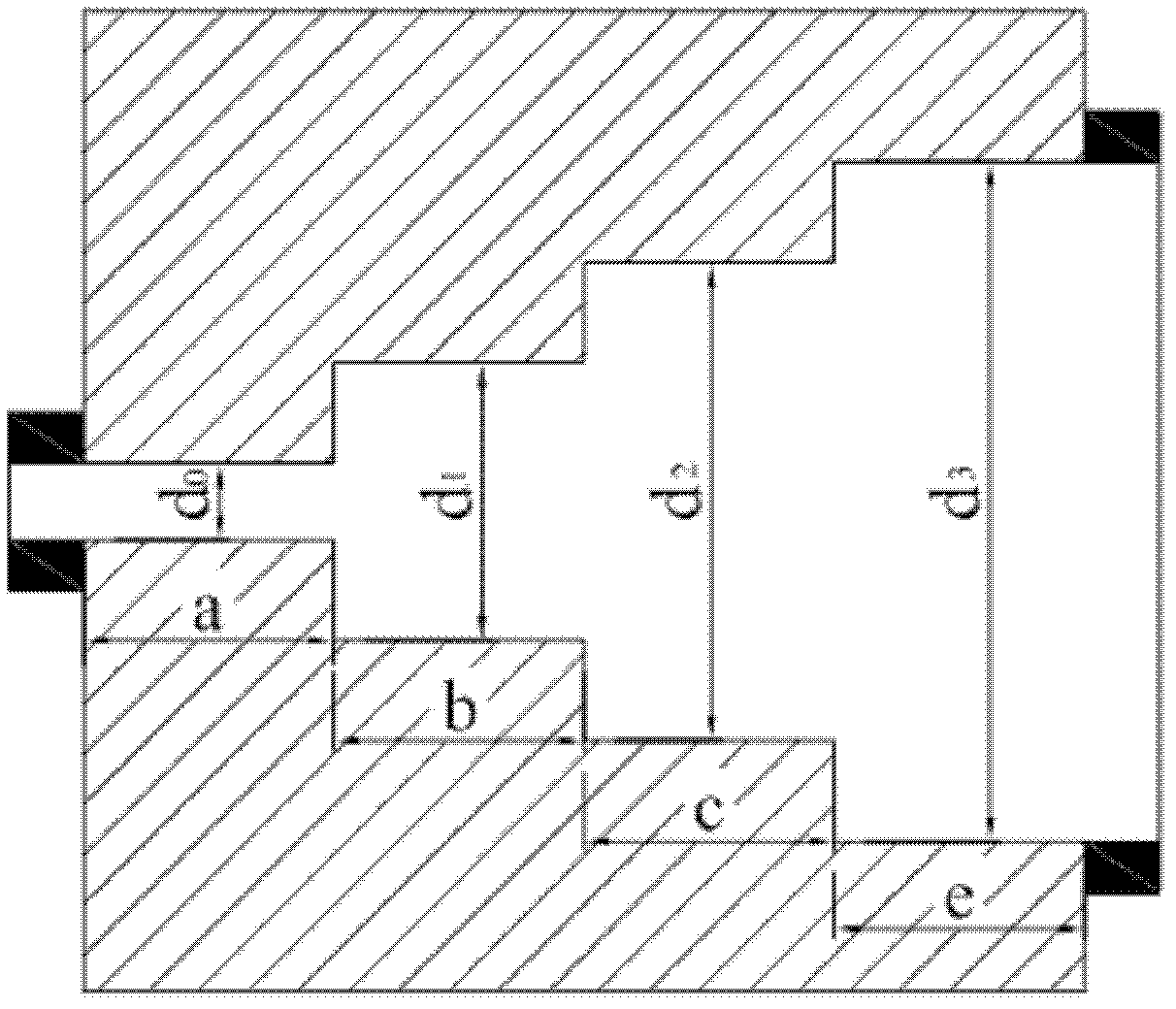

[0077] A jet cavitation device such as figure 1 As shown, the cavitation generator as image 3 As shown, the process for preparing two-dimensional nanomolybdenum disulfide by jet cavitation method is:

[0078] The first step: 4.9% molybdenum disulfide powder with an average particle size of 25 μm, 3.1% sodium lauryl sulfate and 92% water to prepare a molybdenum disulfide aqueous solution with good dispersion stability, and put it into the storage tank 1 ;

[0079] The second step: set the working pressure of the plunger pump 5 to 40MPa, open the valve 3 at the water inlet pipe 2, the molybdenum disulfide aqueous solution enters the plunger pump 5 from the storage tank 1, and start the motor 4 to run the system, and the molybdenum disulfide aqueous solution is Pressurize to a specified pressure of 40Mpa; the power of the motor 4 is 30KW;

[0080] The third step: the pressurized molybdenum disulfide aqueous solution enters the cavitation generator 8 through the high-pressure ...

Embodiment 3

[0086] A jet cavitation device such as figure 1 As shown, the cavitation generator as figure 2 As shown, the process for preparing two-dimensional nanomolybdenum disulfide by jet cavitation method is:

[0087] The first step: 9.1% molybdenum disulfide powder with an average particle size of 45 μm, 4.9% sodium lauryl sulfate and 86% water are used to prepare a molybdenum disulfide aqueous solution with good dispersion stability, and put it into the storage tank 1 ;

[0088] Step 2: Set the working pressure of the plunger pump 5 to 70MPa, open the valve 3 at the water inlet pipe 2, the molybdenum disulfide aqueous solution enters the plunger pump 5 from the storage tank 1, start the motor 4 system operation, and the molybdenum disulfide aqueous solution is Pressurize to a specified pressure of 70Mpa; the power of the motor 4 is 30KW;

[0089] The third step: the pressurized molybdenum disulfide aqueous solution enters the cavitation generator 8 through the high-pressure pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com