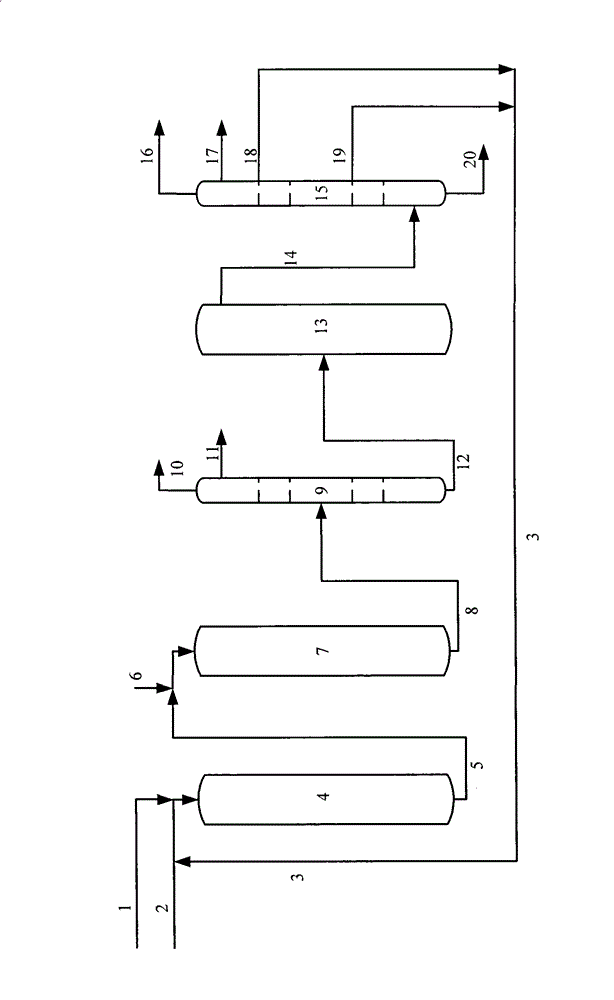

Method for producing light olefins and monocyclic aromatic hydrocarbons from heavy hydrocarbons

A technology for low-carbon olefins and single-ring aromatics, which is applied in the field of producing low-carbon olefins and single-ring aromatics from heavy hydrocarbons in the hydrogenation-catalytic cracking combined process, which can solve the problems of increasing the production of high-value target products, and achieve property improvement and impurity removal. The effect of increasing the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 adopts the method provided by the invention:

[0047] The first hydrogenation reaction zone (one reverse) is filled with 200ml of wax oil hydrofinishing preparation A, and the second hydrogenation reaction zone (two reverse) is filled with B, C and D catalysts from top to bottom, a total of 400ml, the filling volume The ratio is 5:45:50. The mixed oil of wax oil and heavy cycle oil (mass ratio 9:1) is first hydrotreated through the first reaction at a flow rate of 320g / h, and then mixed with residual oil at the flow rate of 80g / h at the outlet of the first reaction, and then enters the second reaction for addition. hydrogen reaction. The reaction pressure of the first reaction and the second reaction are both 10.0MPa, and the reaction temperature is 370°C. The effluent after the reaction is cooled and separated, the hydrogen-containing gas is recycled, and the liquid product enters the fractionation system. Gases and a small amount of hydrogenated naphth...

Embodiment 2

[0056] Embodiment 2 adopts the method provided by the invention:

[0057] The first reverse is loaded with 250ml of wax oil hydrofinishing preparation A, and the second reverse is filled with B, C, D and E catalysts from top to bottom in sequence, a total of 400ml, and the filling volume ratio is 5:45:45:5. After wax oil, heavy cycle oil and light cycle oil are mixed at a mass ratio of 320:32:48, the mixed oil is firstly hydrotreated through the first reverse at a flow rate of 400g / h, and mixed at the flow rate of 80g / h at the first reverse outlet Residual oil is then subjected to secondary reaction for hydrogenation reaction. The reaction pressure is 9.0MPa, the first reaction temperature is 365°C, and the second reaction temperature is 380°C. The effluent after the reaction is cooled and separated, the hydrogen-containing gas is recycled, and the liquid product enters the fractionation system. Hydrogen sulfide and a small amount of light distillate are fractionally distill...

Embodiment 3

[0060] Embodiment 3 adopts another form of the method provided by the invention:

[0061] The first reverse is loaded with 250ml of wax oil hydrofinishing preparation A, and the second reverse is filled with B, C, D and E catalysts from top to bottom in sequence, a total of 400ml, and the filling volume ratio is 5:45:45:5. After wax oil, heavy cycle oil and light cycle oil are mixed at a mass ratio of 320:24:36, the mixed oil is firstly hydrotreated through the first reverse at a flow rate of 380g / h, and mixed with a flow rate of 100g / h at the first reverse outlet Residual oil mixed oil enters secondary reaction to carry out hydrogenation reaction again, and the composition of used residual oil mixed oil is residual oil:heavy cycle oil:light cycle oil=80:8:12 (mass ratio). The reaction pressure is 9.0MPa, the first reaction temperature is 365°C, and the second reaction temperature is 380°C. The effluent after the reaction is cooled and separated, the hydrogen-containing gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com