Premelted slag for unpolluted deoxidization with externally applied voltage between metal and slag and preparation method thereof

A technology of applying an external electric field and pre-melting slag, which is applied in the field of steelmaking and refining technology, can solve the problems of poor stability of slag, dust pollution, and difficult control, and achieve the effect of simple production method, no dust pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by way of examples.

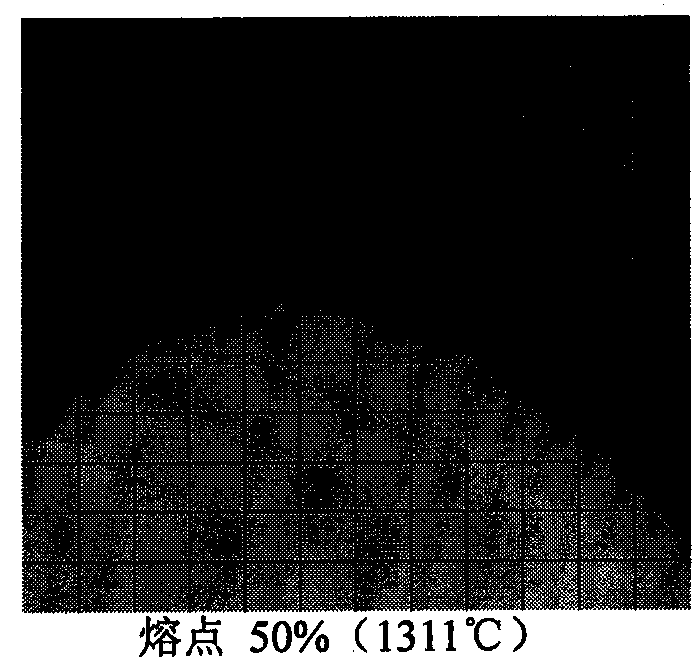

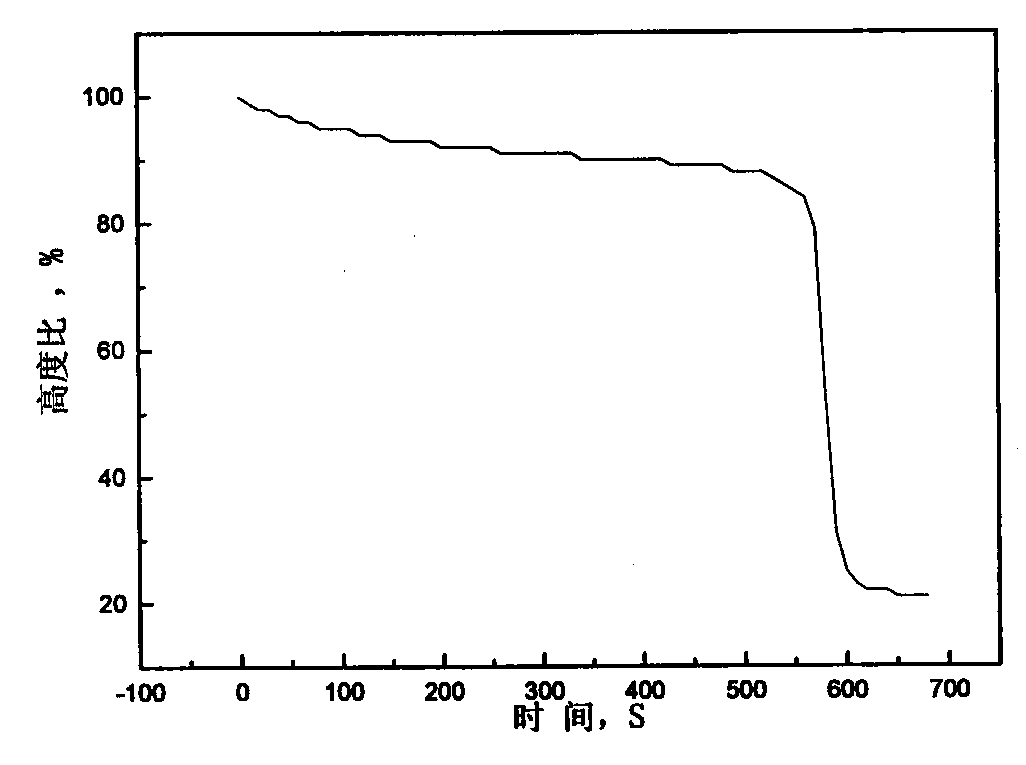

[0033] Mix the crushed limestone, iron oxide scale, aluminum powder and MgO powder in a certain proportion, put them into the mixer and mix them for 30 minutes, then put them into the heating furnace to heat the raw materials until they melt, and keep them for 10 minutes to ensure the composition of the slag uniform, then air-cool the molten slag to room temperature, and finally break the frit into pre-melted slag blocks with a particle size of 2-40 mm. The composition and process of the pre-melted slag are shown in Table 1.

[0034] Table 1 The composition and technology of the pre-melted slag of the embodiment of the present invention

[0035]

[0036] The application test of the non-polluting deoxidation pre-melted slag in the slag-gold room of the embodiment of the present invention is carried out on a 500Kg multifunctional induction furnace. For DC electric field, see Table 2 for speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com