Steel plate for building structure with yield strength of 460 MPa, and manufacturing method thereof

A technology of building structure and yield strength, applied in the direction of temperature control, etc., can solve the problems of complex production process, high carbon equivalent, difficult welding, etc., and achieve the effect of simple chemical composition and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

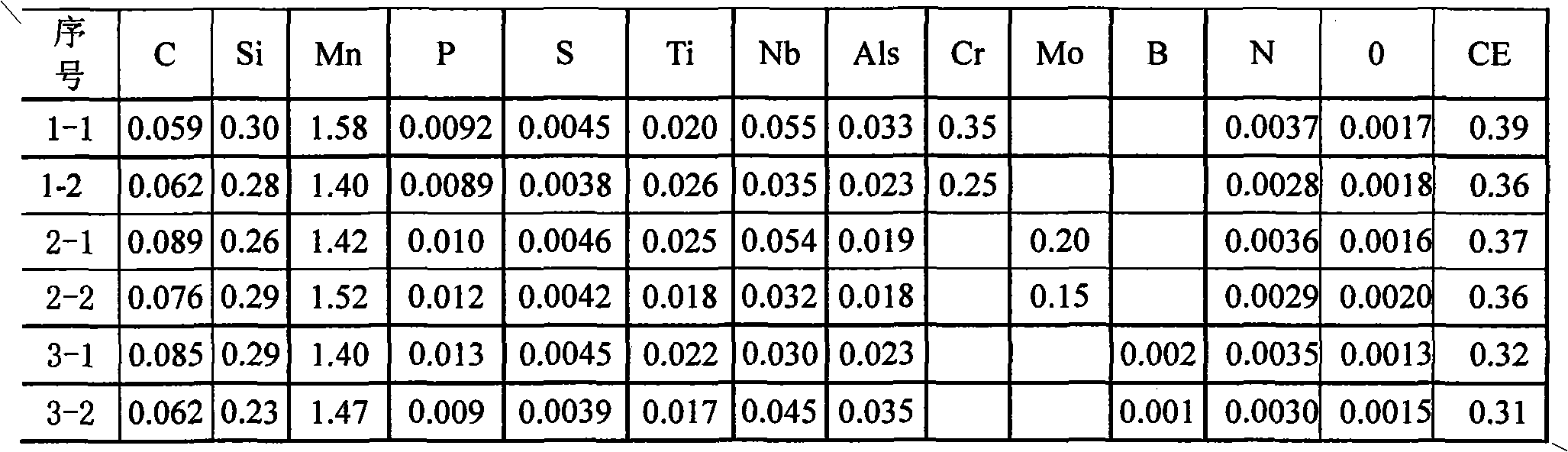

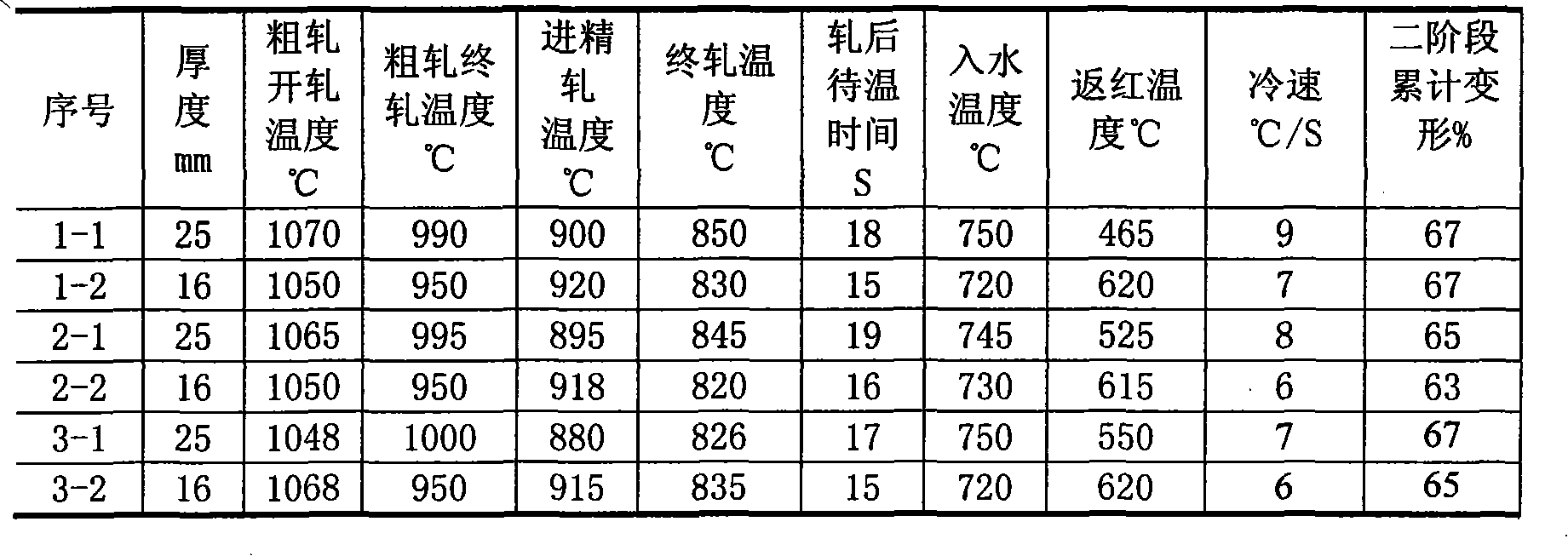

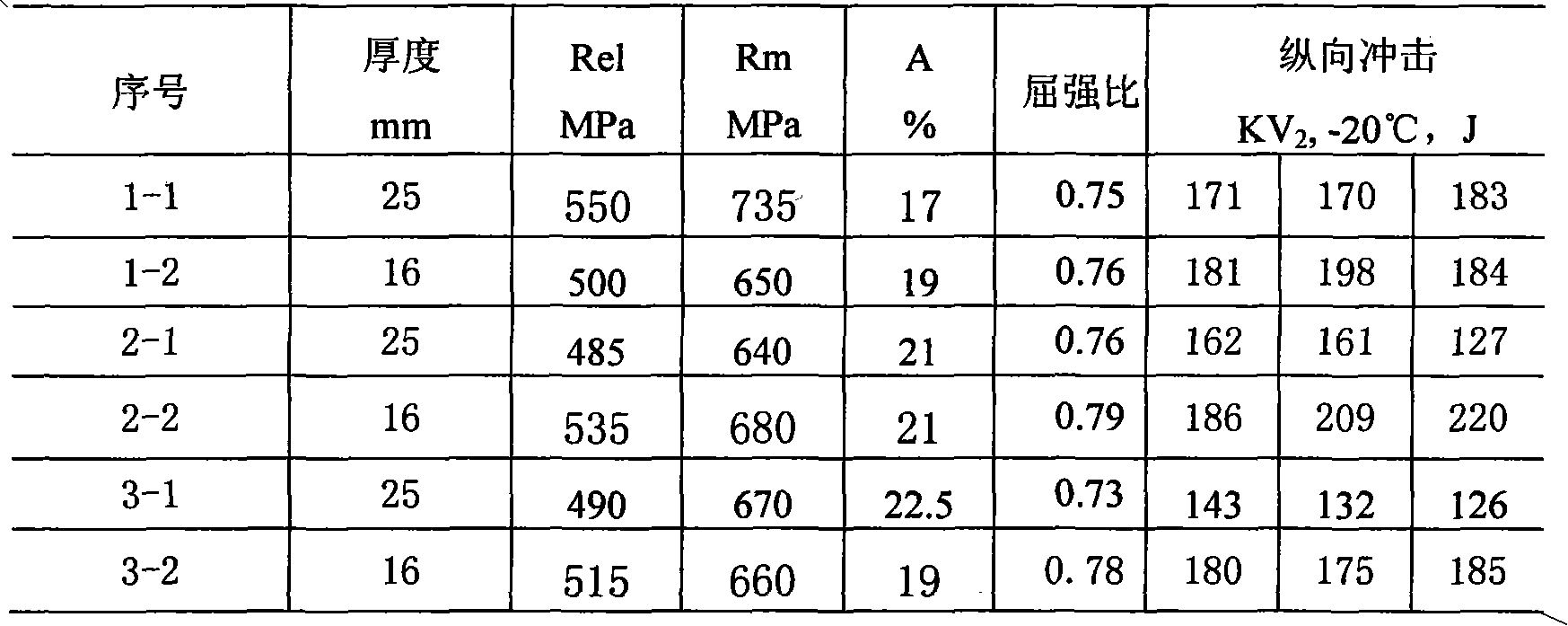

[0024] According to the chemical composition and production process of the present invention, the actual chemical composition of the steel of the present invention is shown in Table 1, the actual rolling process parameters of the steel example of the present invention are shown in Table 2, and the physical performance test results of the present invention are shown in Tables 3 and 4.

[0025] Table 1. Examples of smelting composition of the steel of the present invention, Wt%

[0026]

[0027] Table 2. Actual process parameters of steel examples of the present invention

[0028]

[0029] Table 3 Hot-rolled mechanical properties of steel examples of the present invention

[0030]

[0031] Table 4 Tempering test performance of the 1-1 test plate of the present invention

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com