Permanent magnetic automatic clutch for generator

An automatic clutch and generator technology, applied in the field of clutches, can solve problems such as shell jamming, reduced lubrication effect, high temperature dilution and leakage, etc., to achieve safe and reliable work, prolong service life, and reduce impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

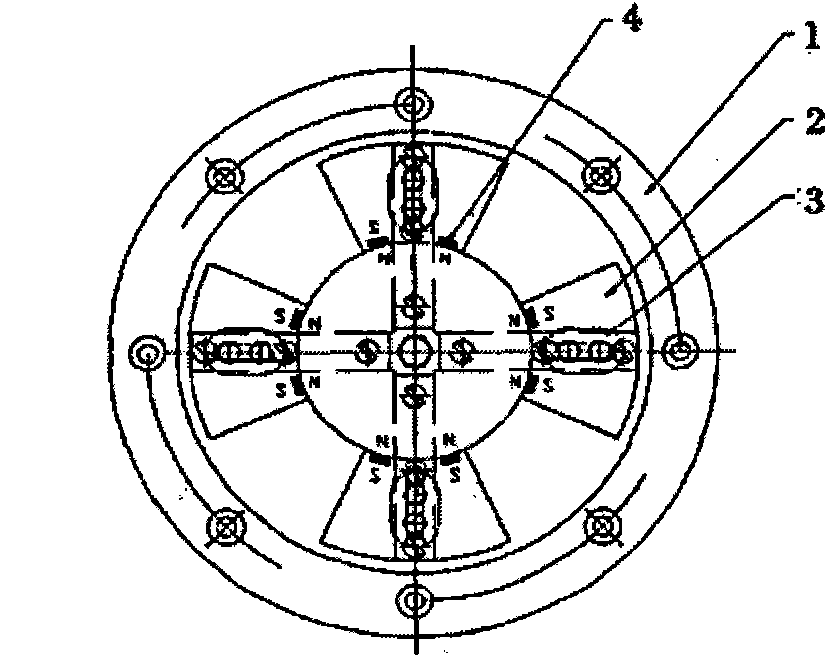

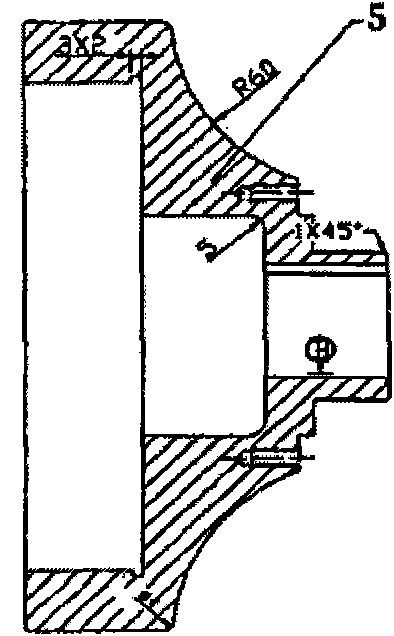

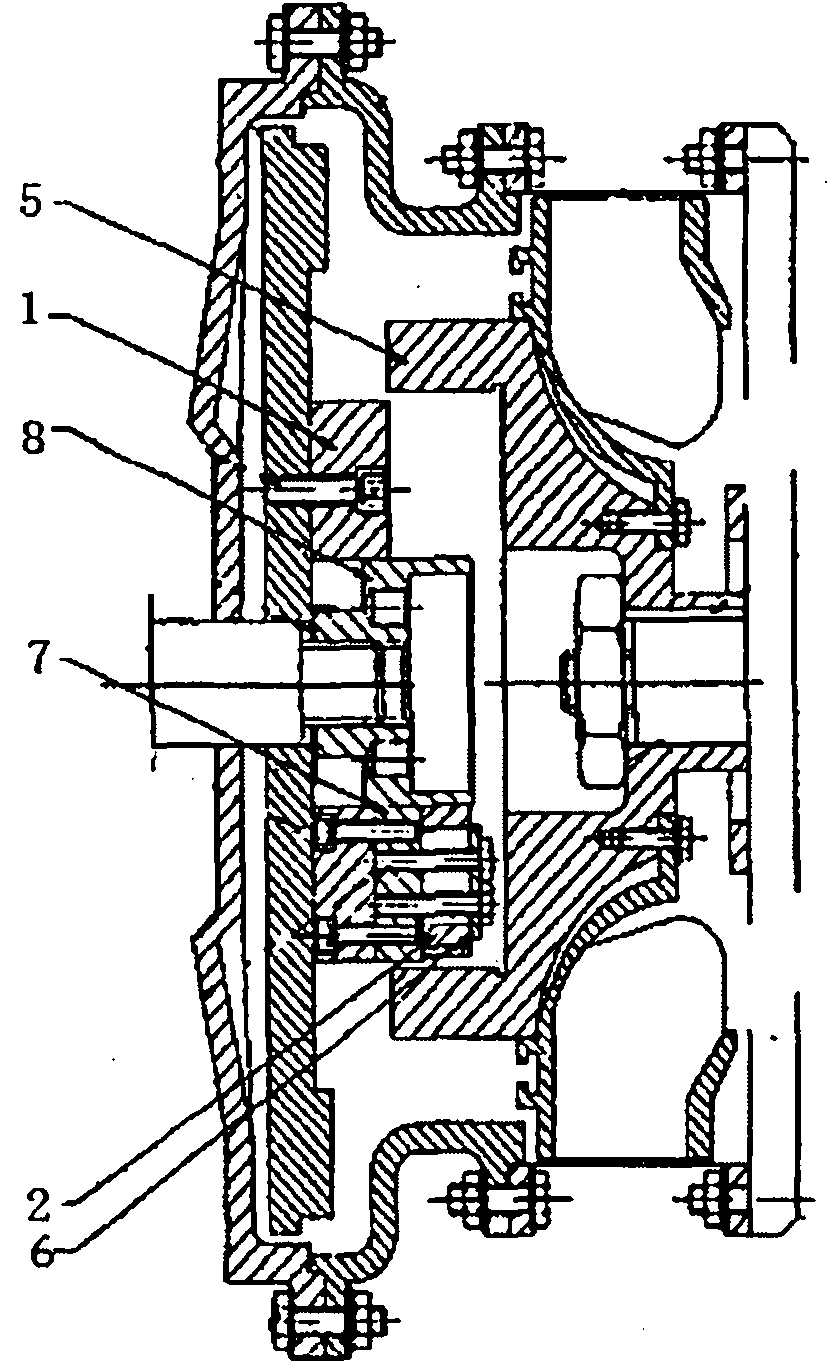

[0020] The purpose of this embodiment is to overcome the problems existing in the structure of the existing clutch, and realize the safe and reliable engagement and separation of the engine and the generator under the dual-frequency and variable-frequency state of the dual-frequency generating set.

[0021] (1) According to the working characteristics of the dual-frequency generator, the clutch design requirements are put forward ① simple structure, small size, light weight, safe work and high efficiency.

[0022] ②The "engagement" of the clutch is reliable, the force-bearing surface is uniform, stable and without impact, and will not cause the vibration of the generator set to exceed the limit. The "engaged" speed range is wide and does not change due to sudden load changes.

[0023] ③The clutch is "separated" completely, and when the load changes in the frequency conversion work and causes vibration, the clutch working element will not change its position.

[0024] ④The "en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com