Device for automatically testing corrosion resistance of stainless steel tableware

An automatic test device, stainless steel technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of long test time, time-consuming, labor-intensive and difficult manual completion of the test, and achieve automatic operation , Save labor intensity, save labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

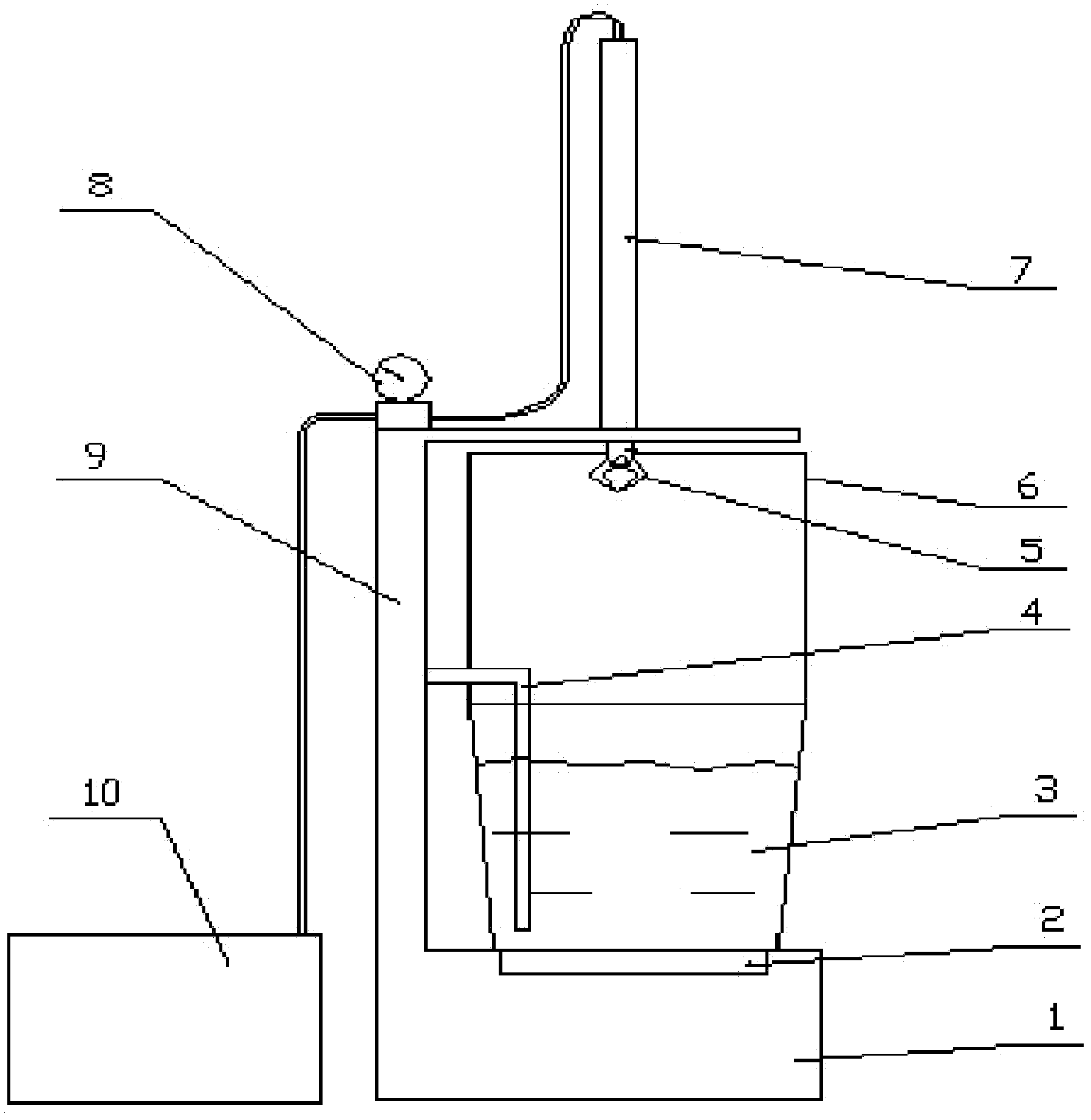

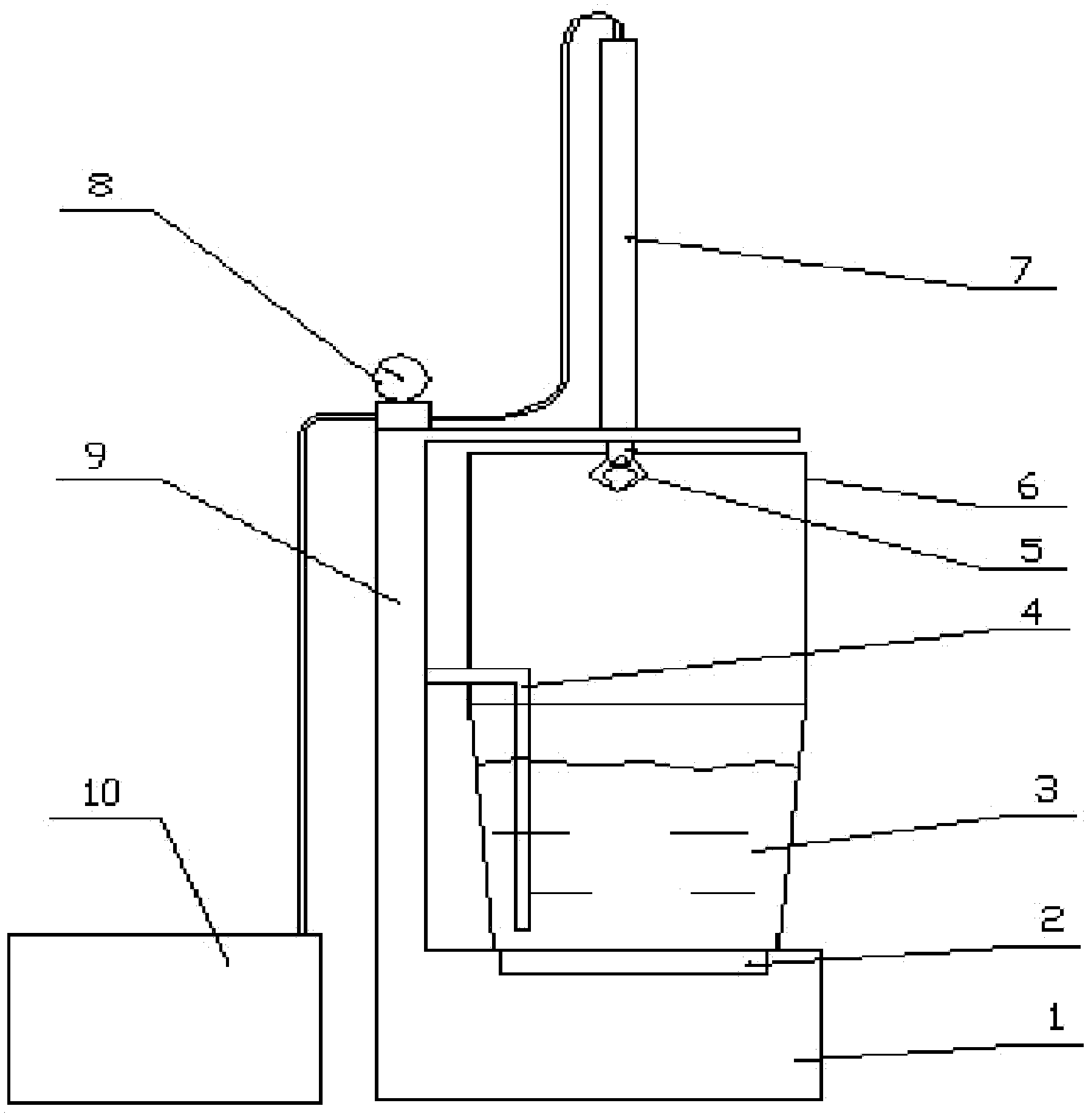

[0016] See figure 1 , which is a schematic structural view of an automatic test device for the corrosion resistance of stainless steel tableware in the present invention.

[0017] The automatic test device for corrosion resistance of stainless steel tableware provided by the present invention comprises a support frame 9, a base console 1, a cylinder 7 and a liquid container 3, the support frame 9 is installed on the base console 1, and the liquid container 3 is placed on the base console 1, the cylinder 7 is installed on the support frame 9. The cylinder 7 is provided with a hook 5 to connect with the stainless steel tableware sample, and the anti-evaporation cylinder 6 is placed on the top of the liquid container 3. The anti-evaporation cylinder 6 is provided with a cylinder co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com