Substrate of liquid crystal display device, liquid crystal display device and manufacturing method for liquid crystal display device

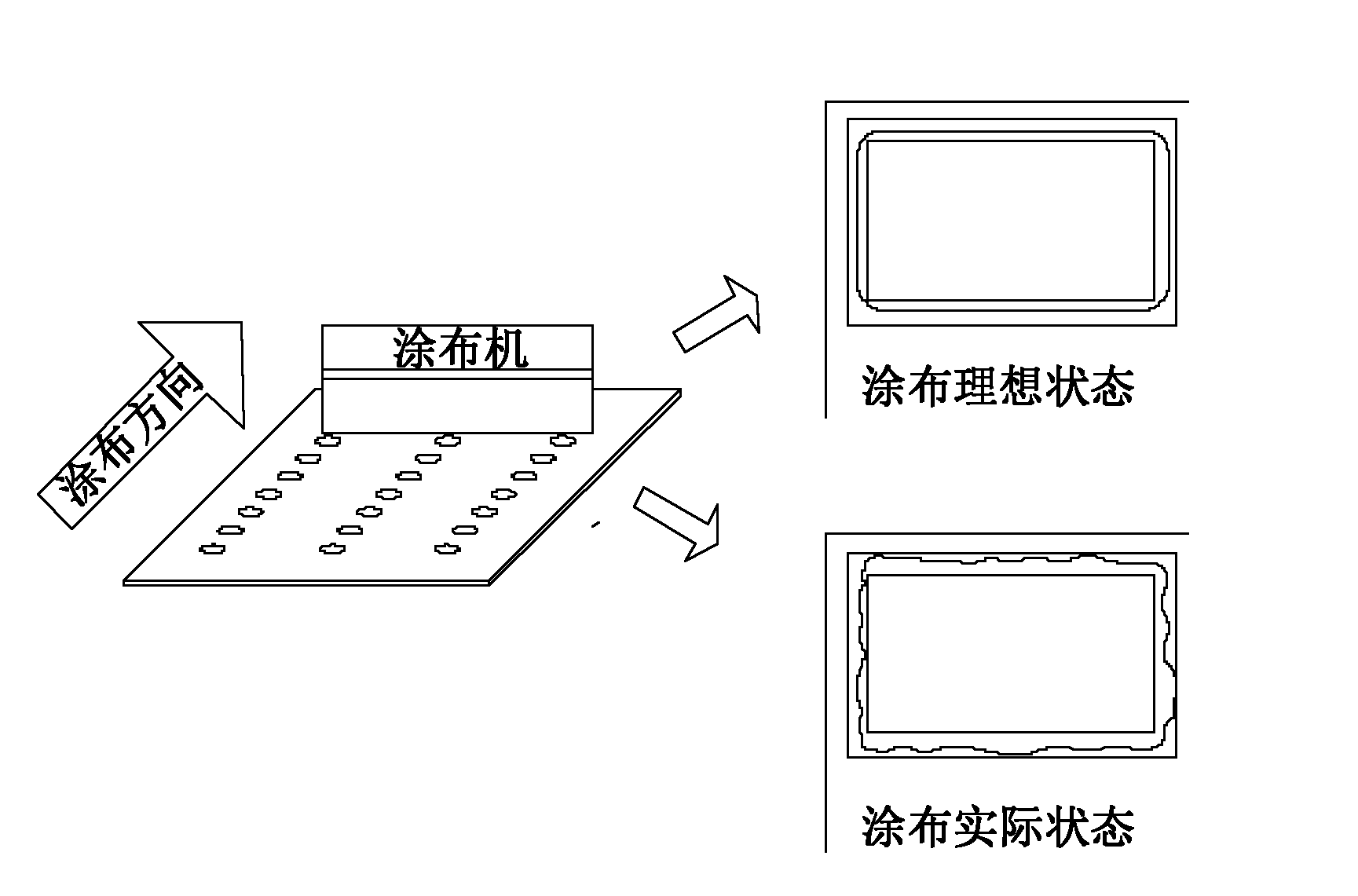

A technology of a liquid crystal display device and a manufacturing method, which is applied in the directions of optics, instruments, nonlinear optics, etc., and can solve problems such as timely transmission of signals, poor bonding of the frame glue 60, and influence on the display range of the liquid crystal display device, so as to expand the range and improve range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

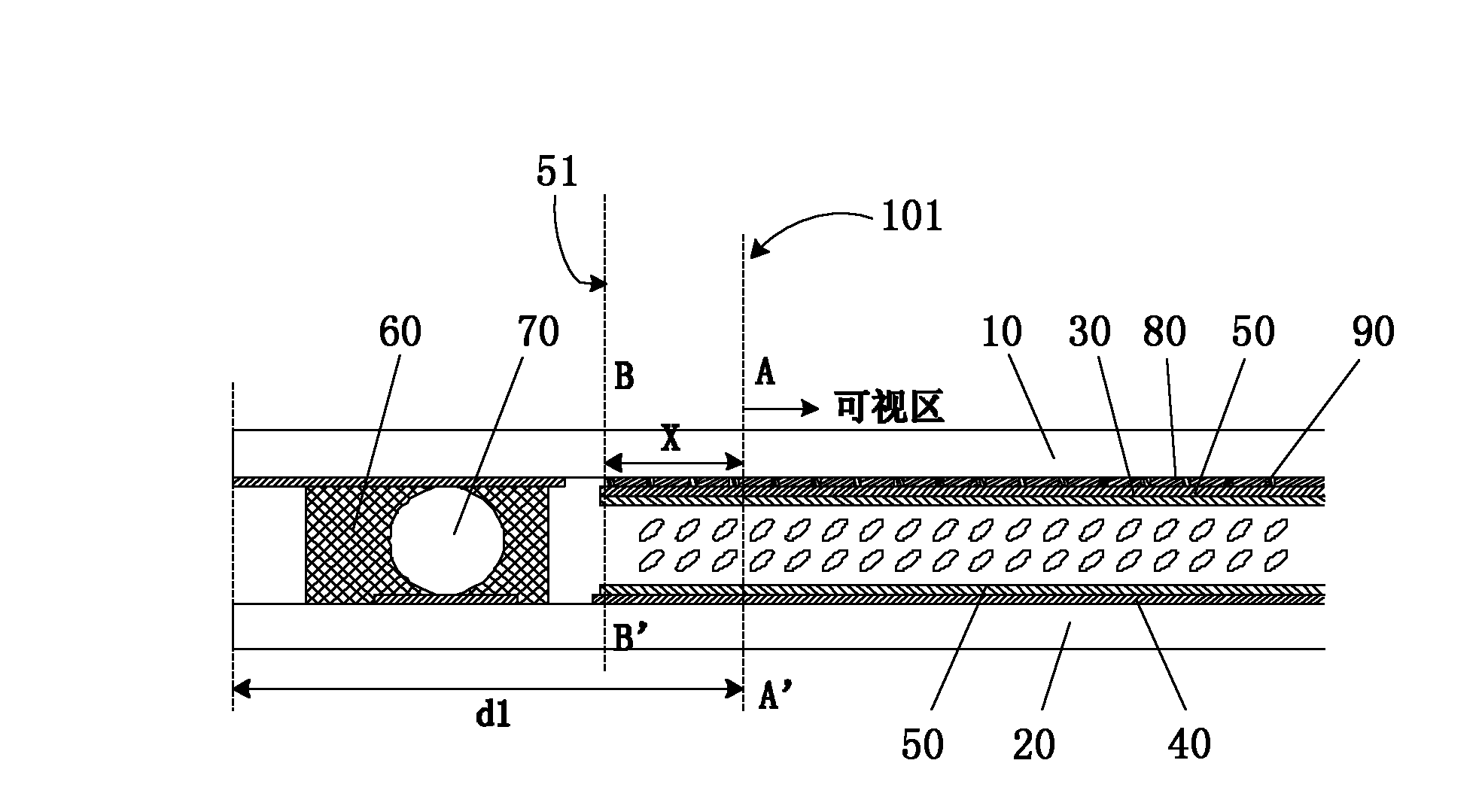

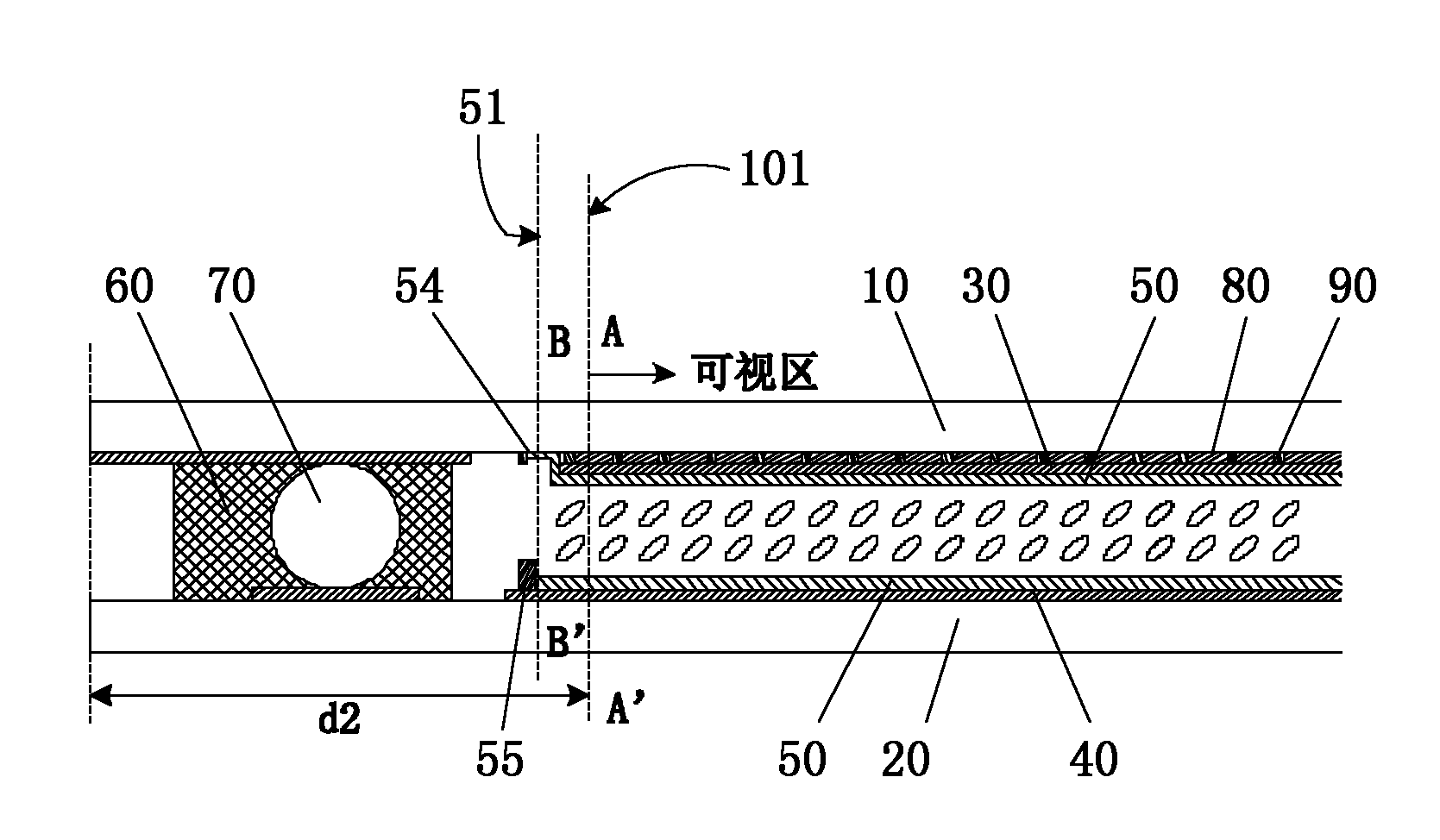

[0034] The present invention provides a liquid crystal display device and a manufacturing method thereof. The liquid crystal display device includes a substrate, and on the substrate, a boss or a groove for preventing the diffusion of the alignment liquid is provided on the boundary of the area where the alignment liquid needs to be coated; The substrate includes an array substrate and a color filter substrate of a liquid crystal display device.

[0035] Such as image 3 Shown is an embodiment of the present invention, and shown in the figure is a structural cross-sectional view of a liquid crystal panel of a liquid crystal display device, which includes an array substrate and a color filter substrate facing each other; the color filter substrate includes an upper glass 10, and the upper glass 10 is arranged There is a color film 80, a black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com