Capacitive touch screen

A capacitive touch screen and electrode technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of high manufacturing cost, difficult to meet the demand, large thickness and size, etc., and achieve product quality rate Improvement, production efficiency improvement, and the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

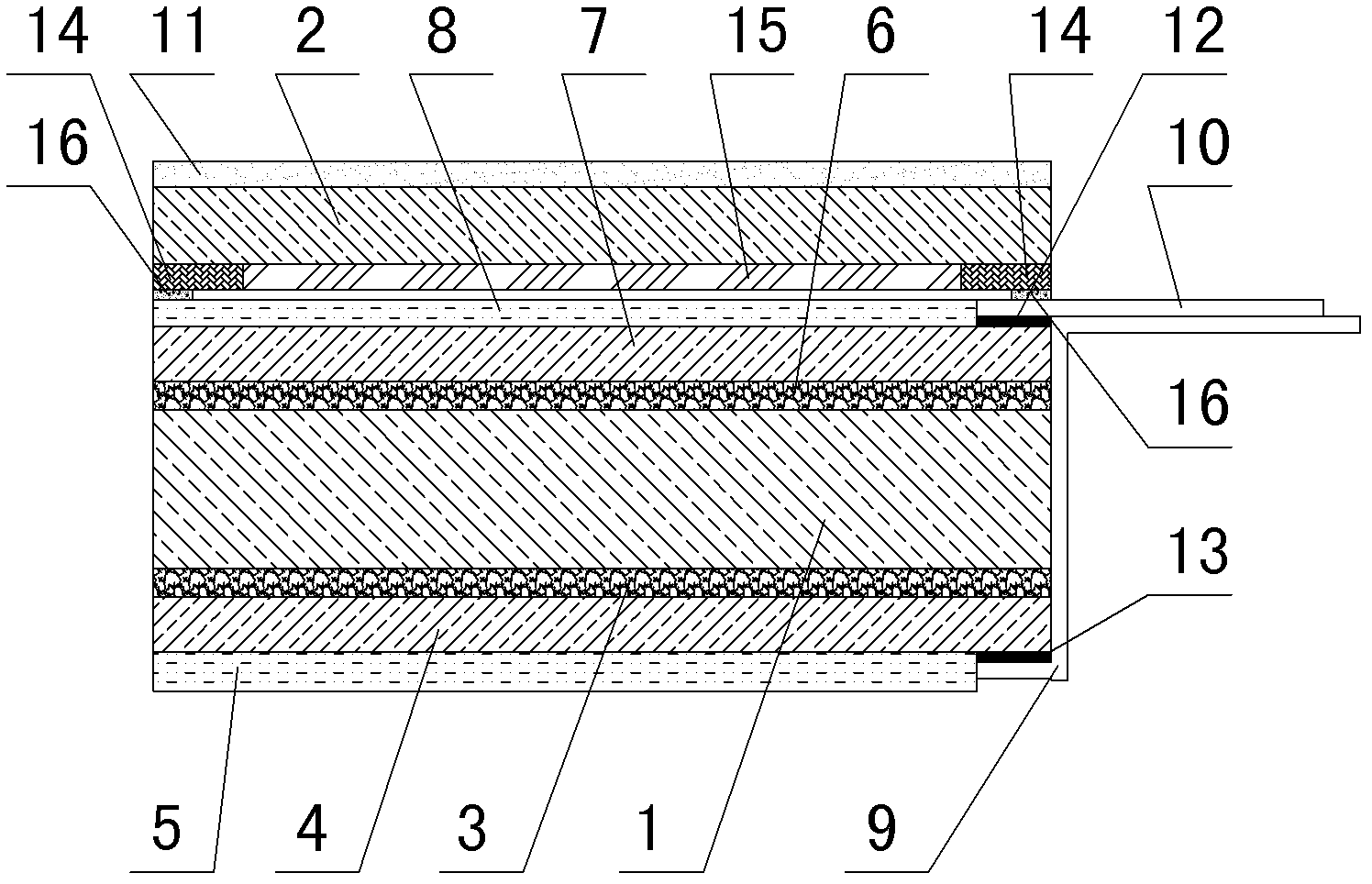

[0027] see Figure 1 ~ Figure 4 A capacitive touch screen includes a substrate assembly and a cover assembly.

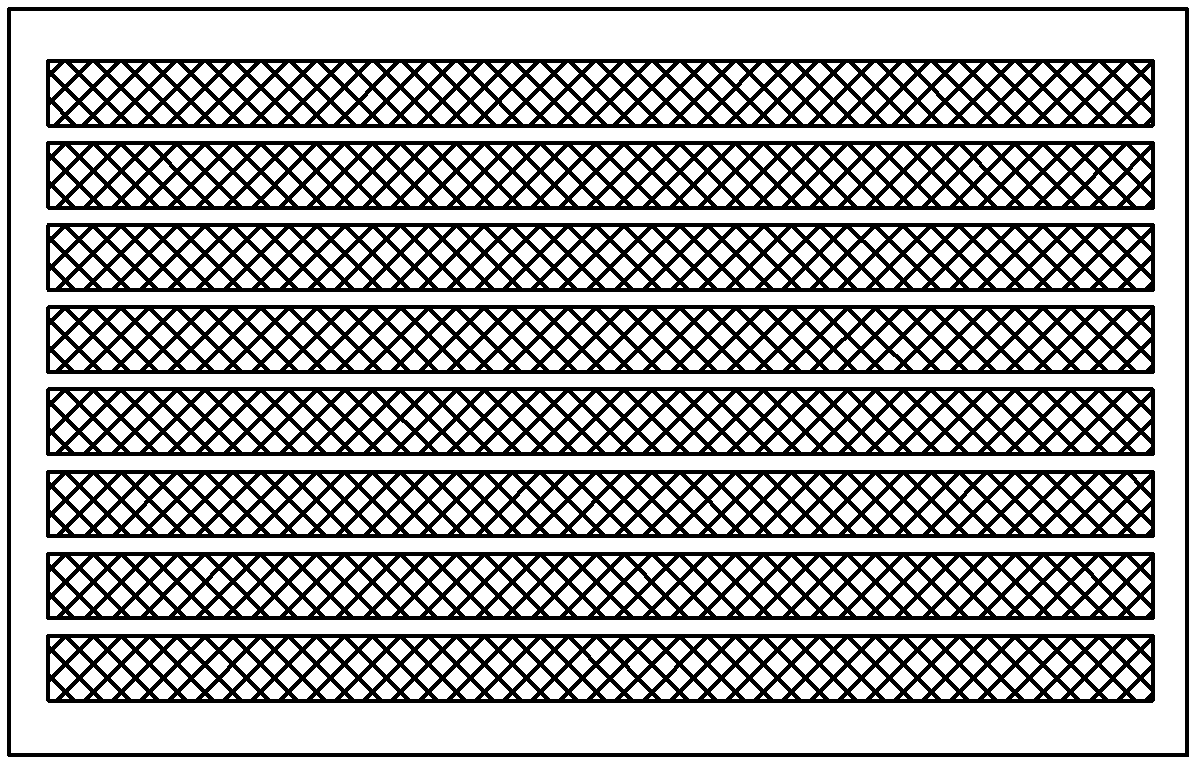

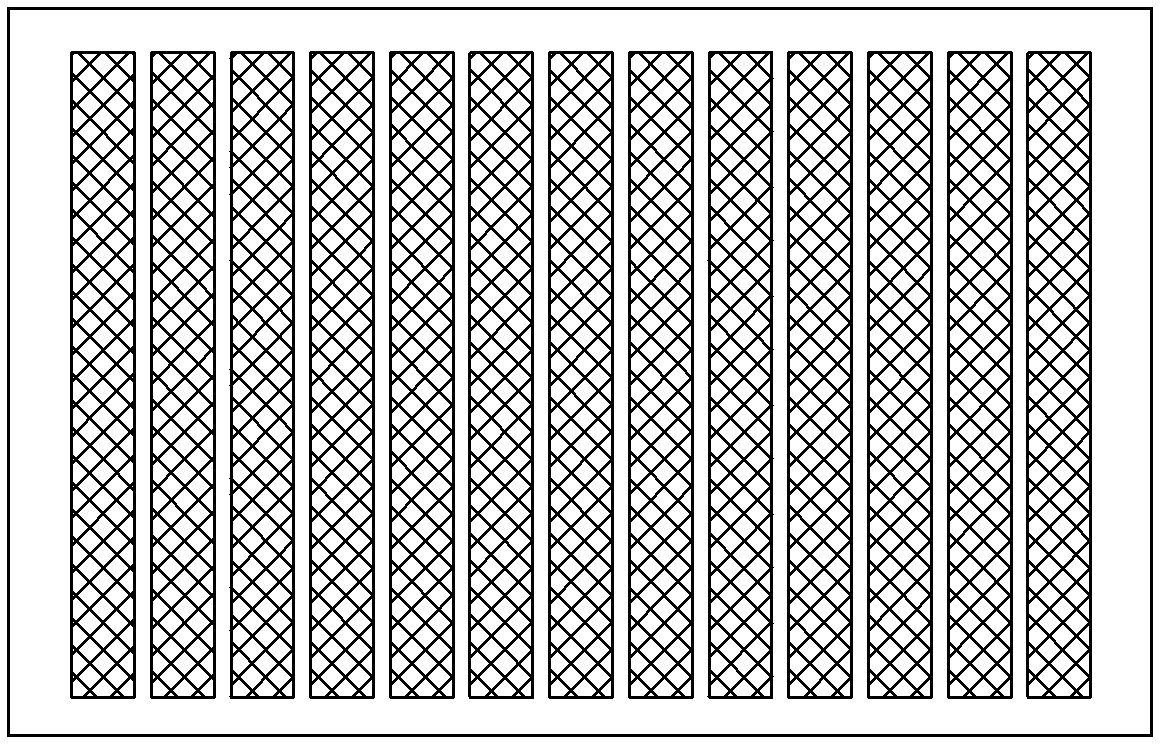

[0028] The substrate assembly includes a substrate 1, and the upper and lower surfaces of the substrate 1 are coated with SiO 2 Membrane 6, 3, a SiO 2 A strip-shaped X-line wire mesh electrode group is formed on the film, and another SiO 2 A strip-shaped Y-column wire mesh electrode group is formed on the film, and wires are connected to the X-row wire mesh electrode group and the Y-column wire mesh electrode group. On the strip-shaped X-row wire mesh electrode group and the strip-shaped Y The array of wire mesh electrodes is covered with a passivation film.

[0029] Fabrication of Substrate Components:

[0030] Vacuum plating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com