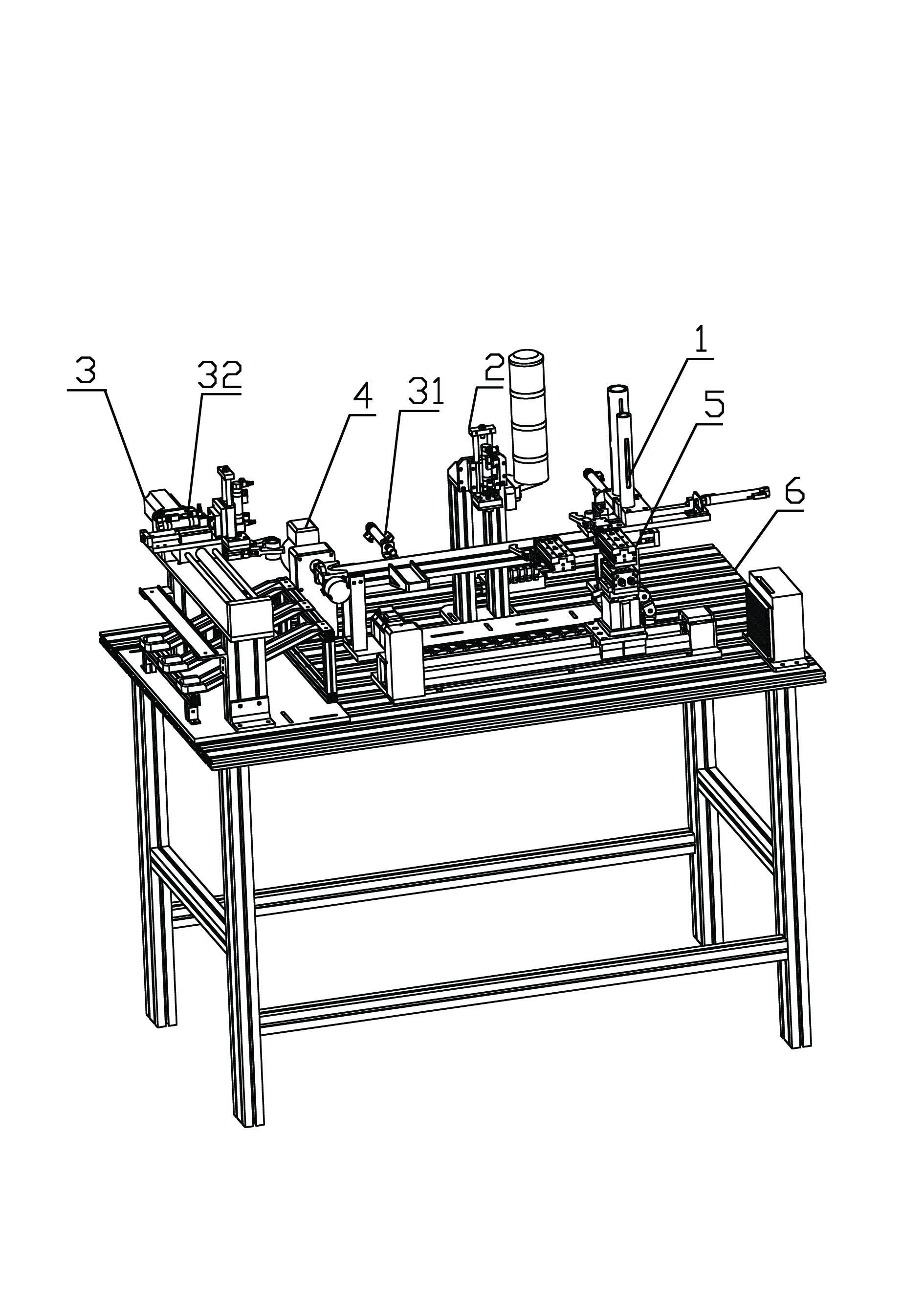

Dynamic assembly motion control training assessment equipment

A technology of motion control and dynamic assembly, applied in the direction of educational appliances, instruments, teaching models, etc., to achieve good results in training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0048] As a preferred specific implementation, the setting method includes the following steps:

[0049] The large workpiece feeding substation 11 and the small workpiece feeding substation 12 respectively carry out the pushing out of the first workpiece and the second workpiece. As long as there is no workpiece in one of the feeding substations, it will stop pushing out the workpiece unless the corresponding workpiece is added again;

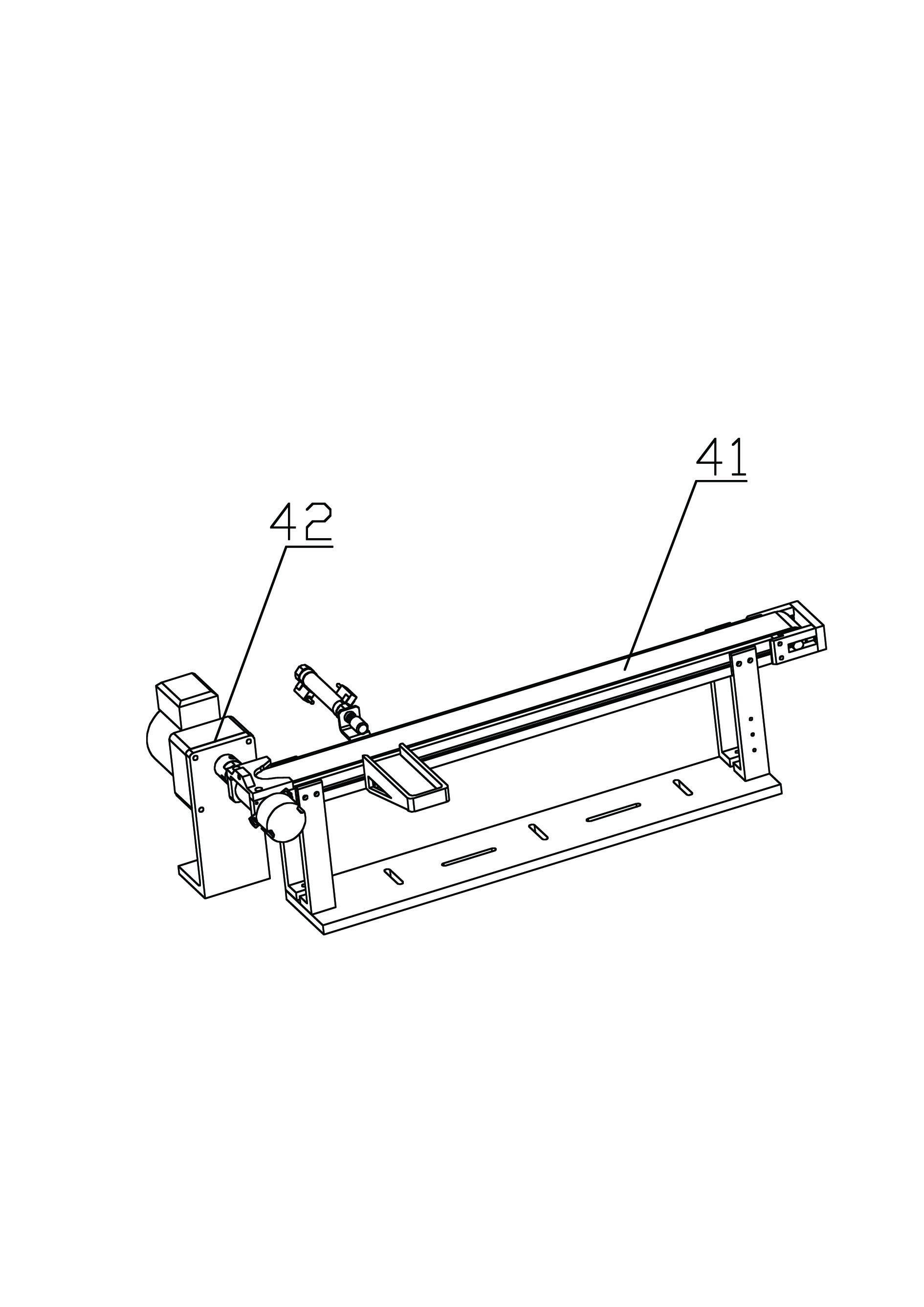

[0050] After the large workpiece feeding station 11 is pushed out, the flat belt 41 starts to transport the first workpiece;

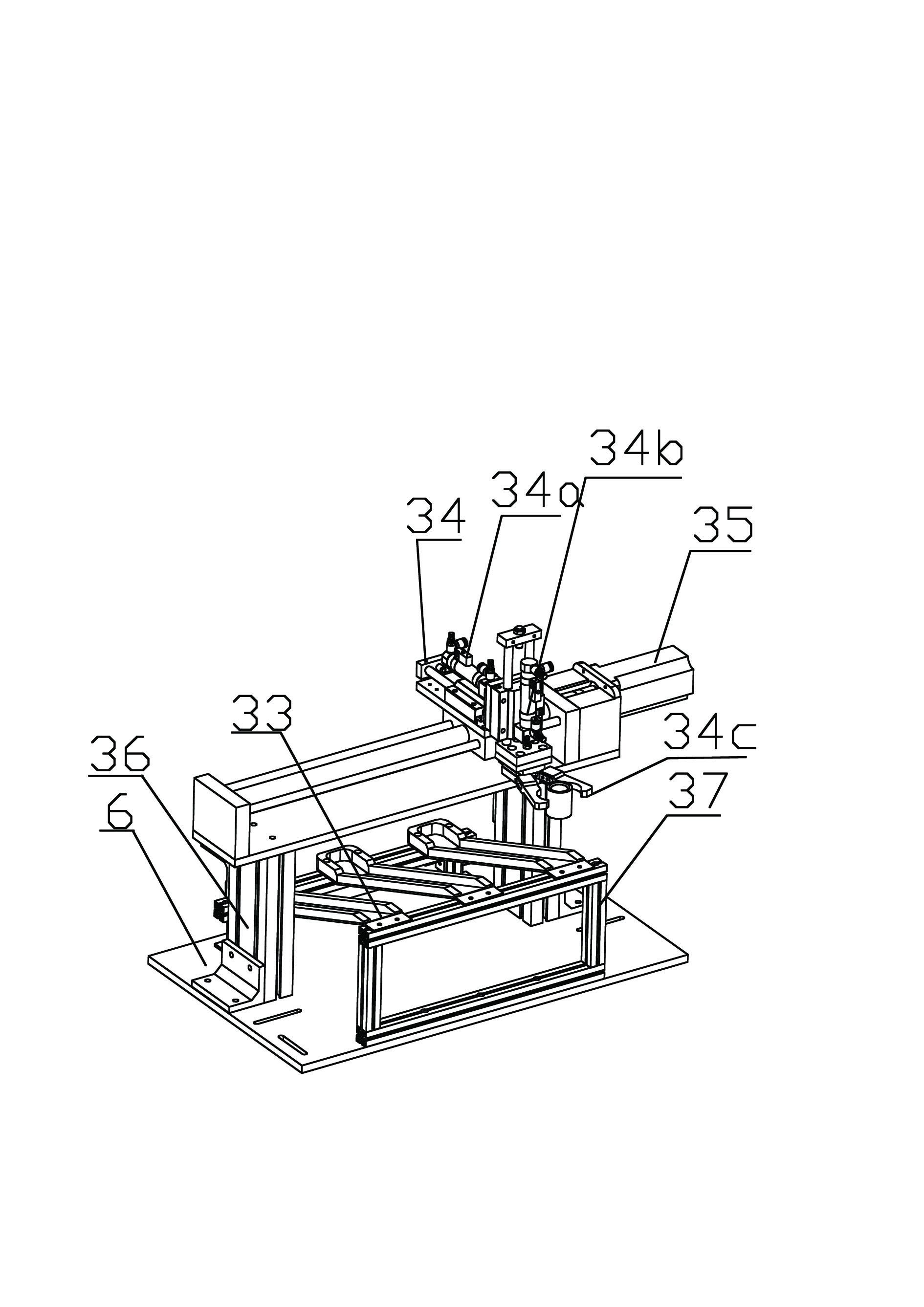

[0051] After the small workpiece feeding station 12 is pushed out, the manipulator claw 51 extends, clamps, lifts, and retracts to take the second workpiece, then turns left, descends, and extends. If the first workpiece has reached the allowable following position, the manipulator claw 51 51 Start following work, otherwise wait;

[0052] After the follow-up synchronization is completed, the manipulator claw 51 is released,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com