Vacuum transmission process equipment and method

A technology of vacuum transmission and process equipment, which is applied in the direction of conveyor objects, transportation and packaging, and final product manufacturing, which can solve the problems of low production efficiency and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

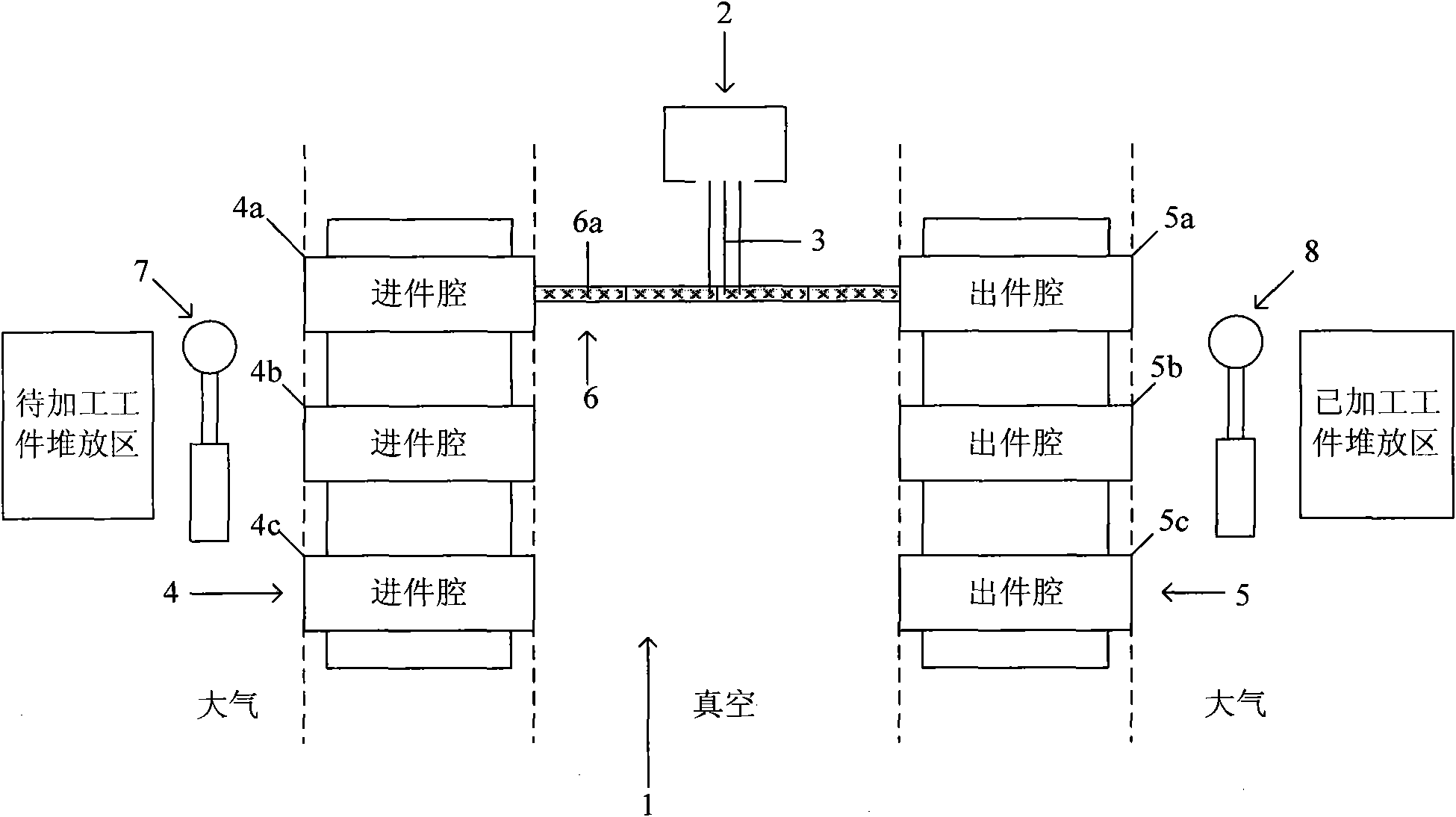

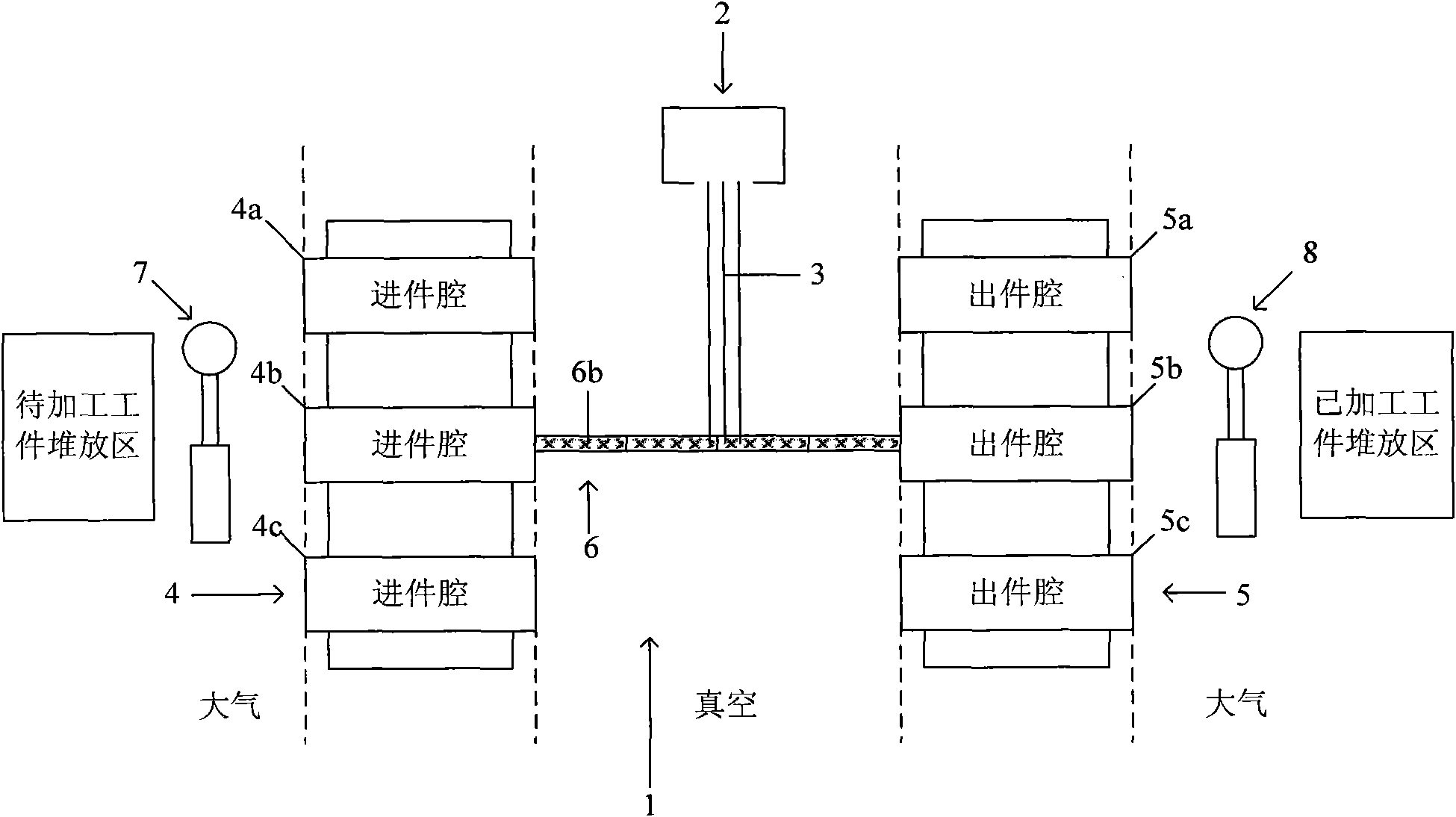

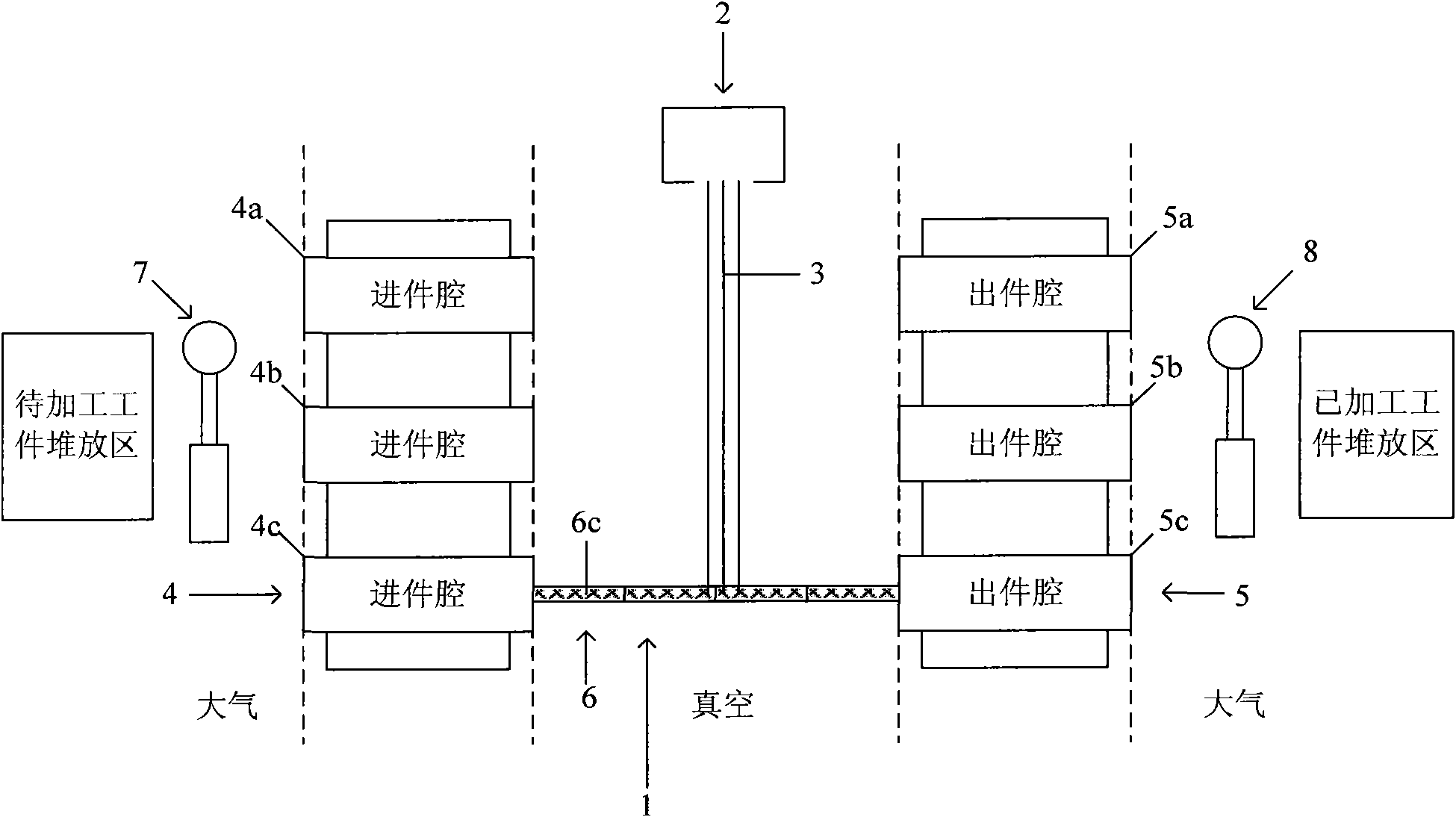

[0020] like Figure 1-3 As shown, the vacuum transmission process equipment of this embodiment first includes a vacuum process chamber 1, and a processing device 2 is arranged in the vacuum process chamber 1, and the processing device 2 uses a processing medium 3 to process the workpiece. The processing device 2 Preferably, the workpiece is processed in a non-contact manner, that is, for example, processing the workpiece with an ion beam or plasma, and at this time the processing medium 3 is correspondingly an ion beam or plasma, and the processing device 2 can also be used for heat treatment or plasma processing of the workpiece. Annealing devices, etc.

[0021] The vacuum transfer process equipment also includes at least two inlet chambers 4 connected to one side of the vacuum process chamber 1, and at least two outlet chambers 5 connected to the other side of the vacuum process chamber 1, each inlet chamber is connected to the other side of the vacuum process chamber 1. Th...

Embodiment 2

[0042] The only difference between the vacuum transmission process equipment in this embodiment and the vacuum transmission process equipment in Embodiment 1 is that in Embodiment 1, the inlet cavity 4-vacuum process cavity 1-outlet cavity 5 forms a linear route, and the transmission Platform 6 reciprocates along this linear route; And in embodiment 2, as Figure 4 As shown, the entry chamber 4->vacuum process chamber 1->outlet chamber 5->atmospheric environment forms a circular route, and the transmission platform 6 is along the Figure 4 The direction indicated by the arrow in the center moves in one direction along the circular route; in addition, since the workpiece loading and workpiece unloading actions for each inlet cavity and outlet cavity can be performed in the same area in the atmospheric environment at this time, so Correspondingly, in Embodiment 2, there is no need to set up two mechanical arms, but only one first mechanical arm 7 needs to be set. It is responsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com