Ion implantation system and methods

An ion implantation system and ion implantation technology, applied in the field of solar wafer manufacturing, can solve the problems of inability to achieve optimal production efficiency, inconvenient control and power supply design, and high cost, so as to improve photoelectric conversion efficiency, improve use safety, and reduce equipment costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

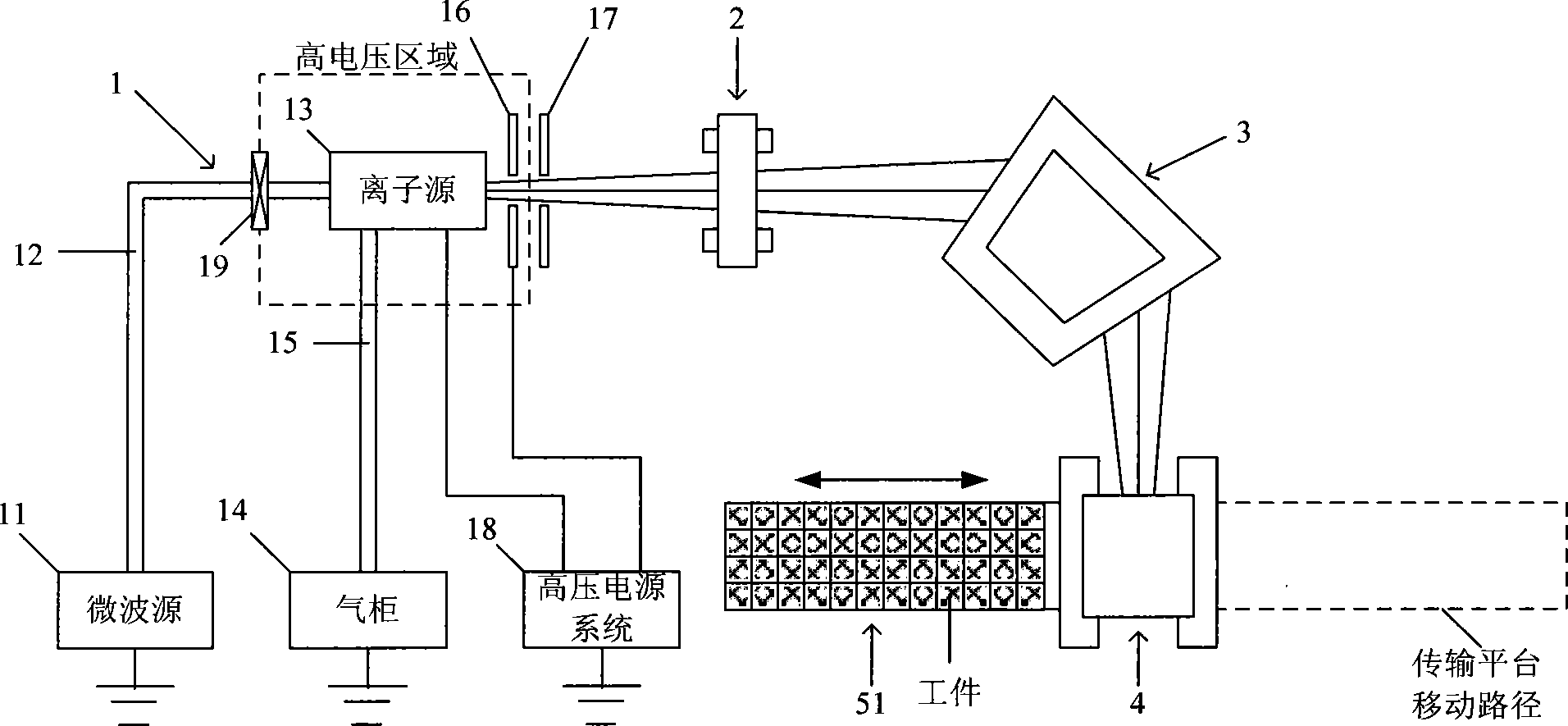

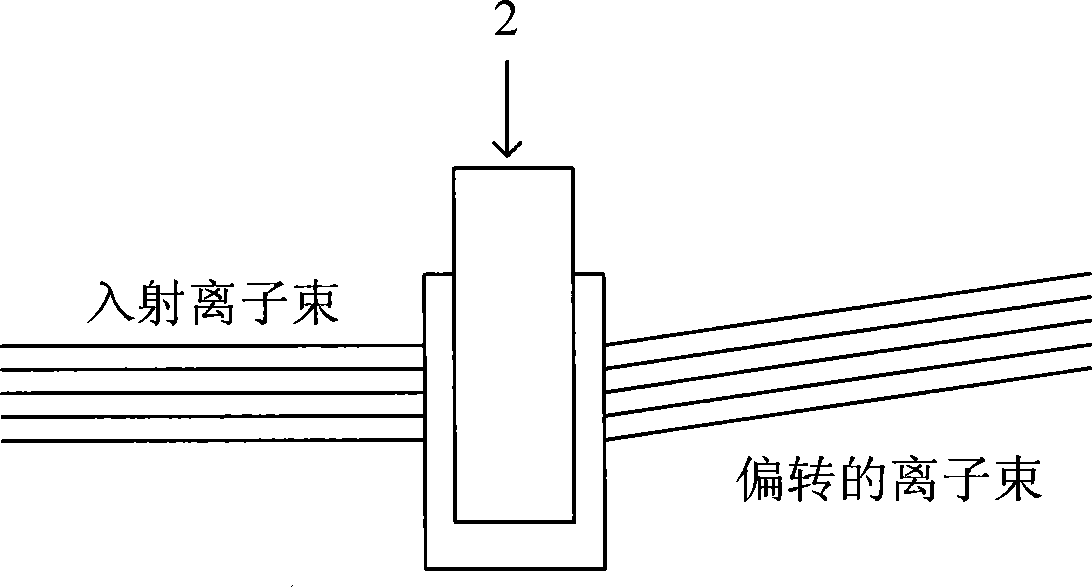

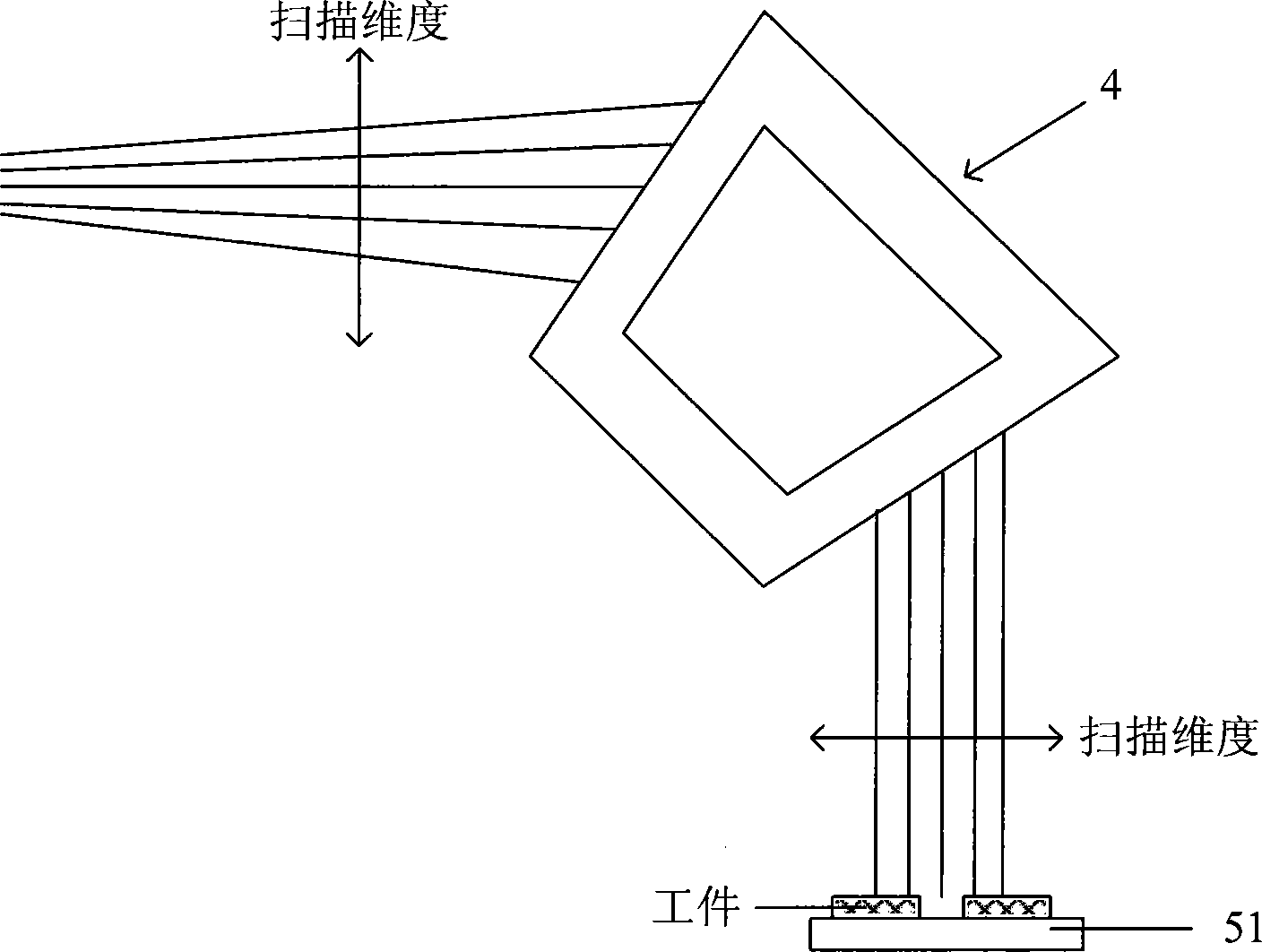

[0054] refer to figure 1 and Figure 6 As shown, the ion implantation system of the present invention first includes an ion source system 1 for generating an ion beam, and the ion beam is transported in a vacuum chamber 6 . On the transmission path of the ion beam, there are successively: a scanning magnet 2, such as figure 2 shown, the scanning magnet 2 will be in the figure 2 The ion beam passing through is continuously scanned up and down within the dimension of the paper, so that the ion beam has a certain angular distribution in the scanned dimension. figure 2 At the moment shown, the scanning magnet 2 is deflecting the passing ion beam upward in the paper dimension, and the scanned dimension of the ion beam is hereinafter referred to as the scanning dimension, figure 1 Before the ion beam arrives at a calibration magnet 4 that will be mentioned below, its scanning dimension is all perpendicular to the paper surface; a mass analysis magnet 3, which makes the ion bea...

Embodiment 2

[0058] The front view of the ion implantation system in this embodiment is as follows Figure 4 As shown, the only difference between this ion implantation system and Embodiment 1 is: firstly, the correction magnet 4 is omitted in this embodiment; secondly, it is assumed that the transmission platform 51 is guaranteed to carry the workpiece and move horizontally as in Embodiment 1 , then the arrangement directions of the ion source system 1, the scanning magnet 2, and the mass analysis magnet 3 in the ion implantation system of this embodiment will differ from those in Embodiment 1 by 90°, but their structures remain the same Change.

[0059] Owing to the omission of the entire magnet system of the calibration magnet 4, not only can the reliability of the entire ion implantation system be significantly improved, but also the length of the ion beam transmission path can be greatly shortened, thus making the design of the beam transmission part simpler.

[0060] but if Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com