Socket power supply connector, a plug power supply connector and component of socket power supply connector and plug power supply connector

A technology for power connectors and sockets, applied in the direction of fixed/insulated contact members, bases/shells, etc., can solve the problems of poor heat dissipation, functional failure, blistering, etc., and achieve good heat dissipation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

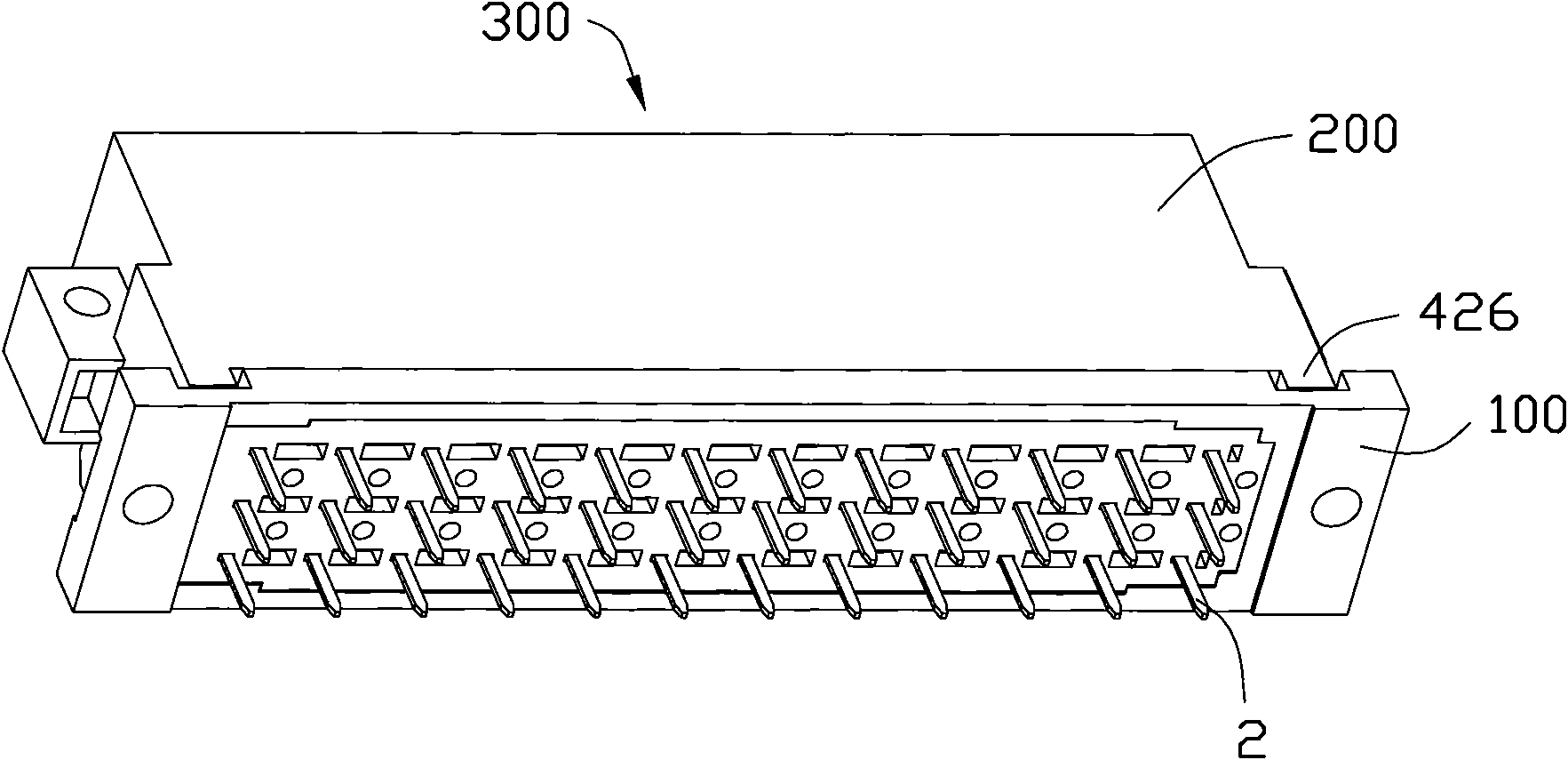

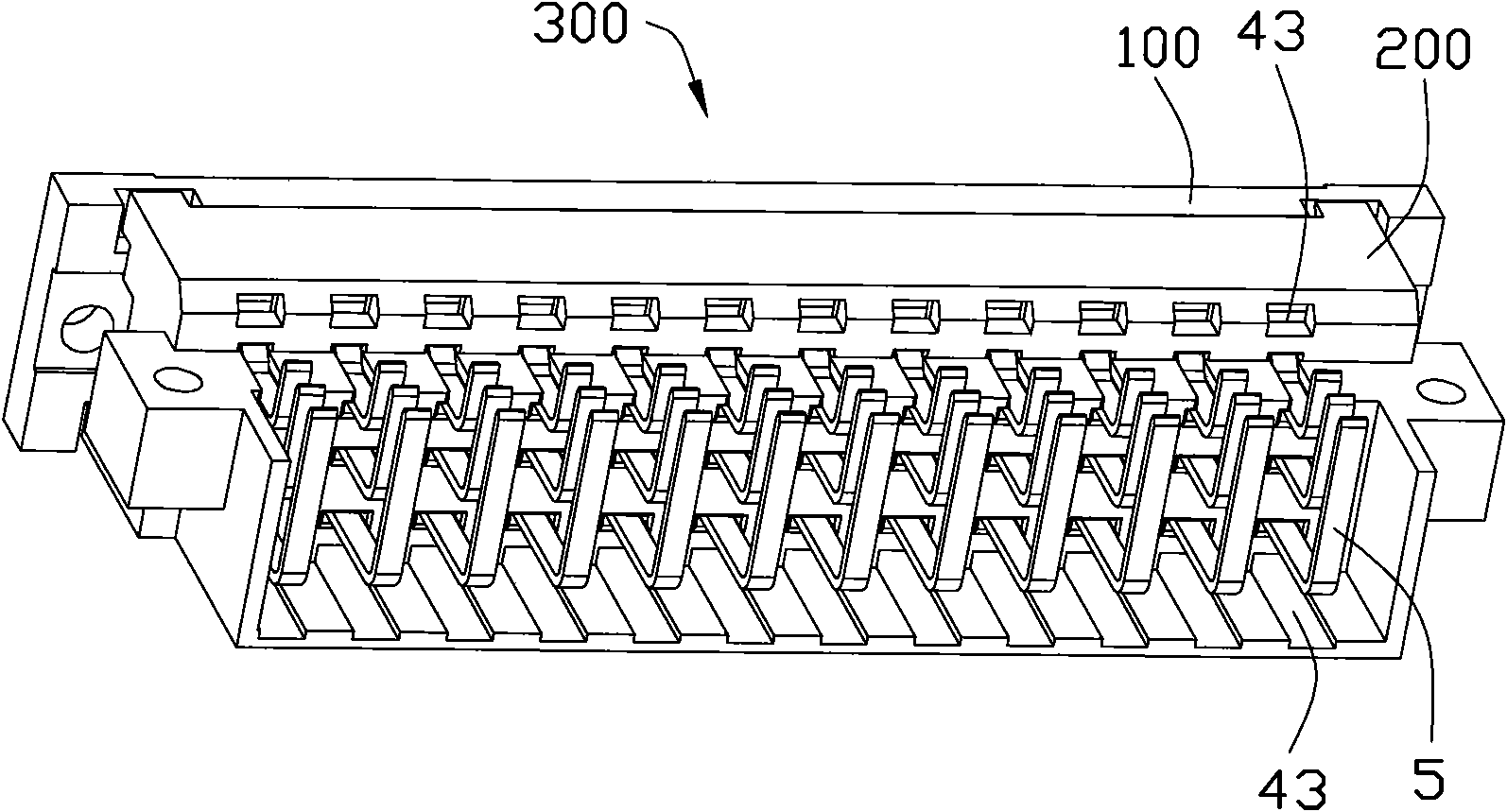

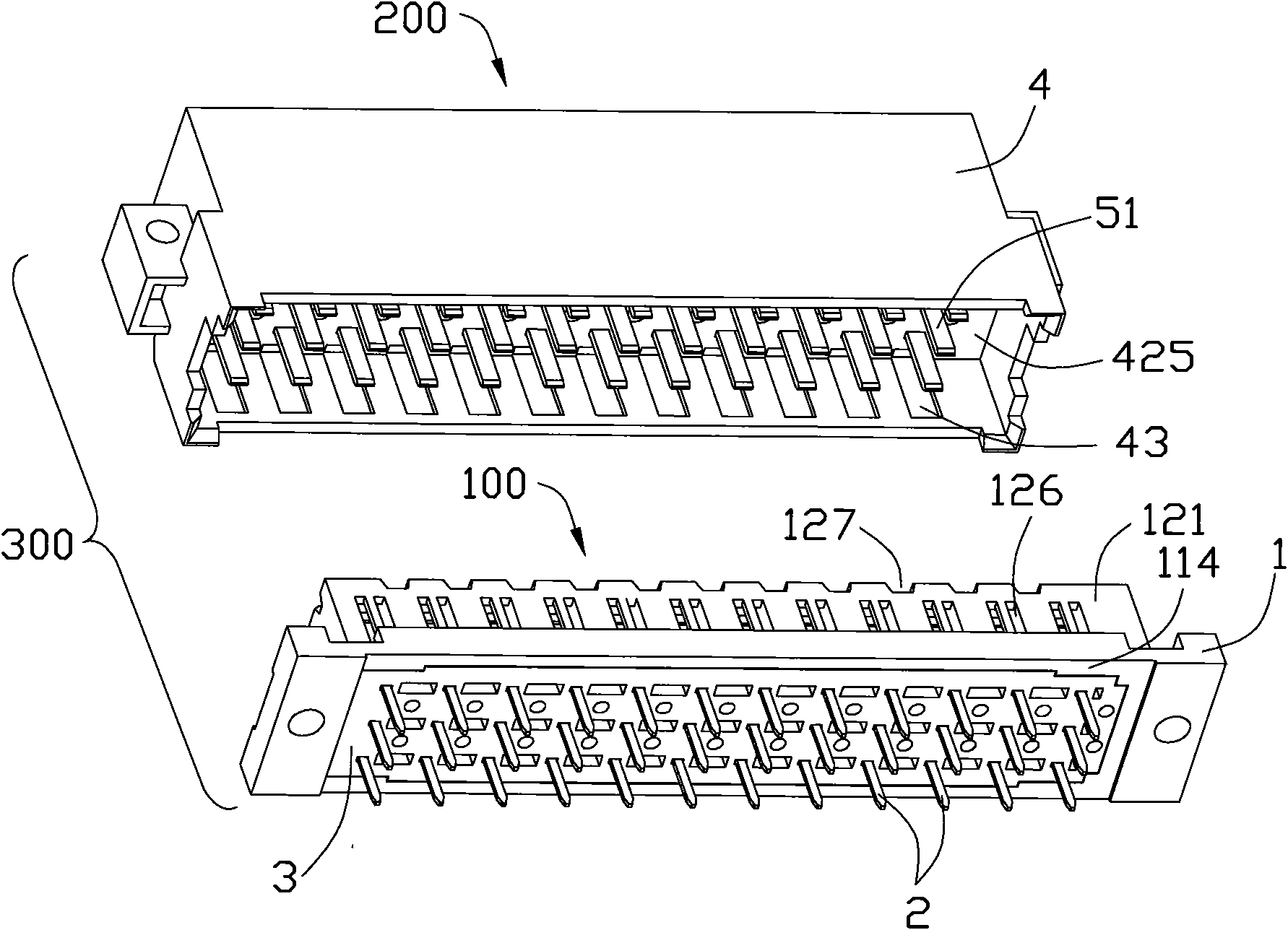

[0043] Please refer to Figure 1 to Figure 3 As shown, the power connector assembly 300 of the present invention includes a receptacle power connector 100 and a plug power connector 200 that cooperate with each other.

[0044] Please refer to Figure 3 to Figure 7 As shown, the socket power connector 100 includes a socket insulating body 1 , a plurality of socket power terminals 2 installed in the socket insulating body 1 , and a positioning block 3 installed on the socket insulating body 1 for positioning the socket power terminals 2 .

[0045] The socket insulating body 1 includes a base portion 11 and a docking portion 12 protruding from the base portion 11 . The base 11 has a top wall 111 , a bottom wall 112 , a front surface 113 and a first installation surface 114 opposite to the front surface 113 . The docking portion 12 integrally extends forward from the front surface 113 of the base portion 11 , and the docking portion 12 shrinks relative to the base portion 11 . Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap