Improved coating coiling device

A technology of coating and coiling, which is applied to the device and coating of the surface coating liquid, which can solve the problems of fire and open flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

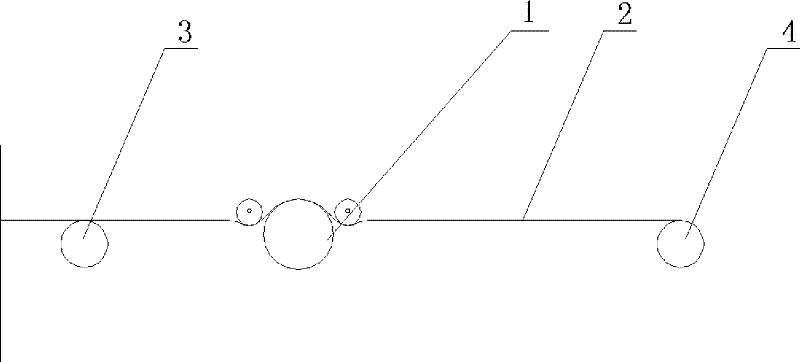

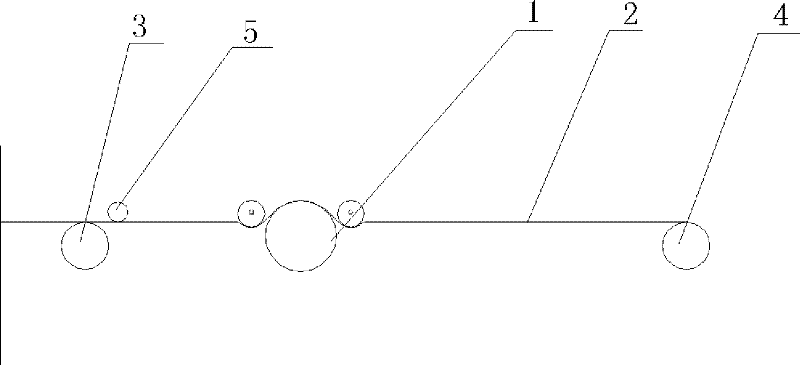

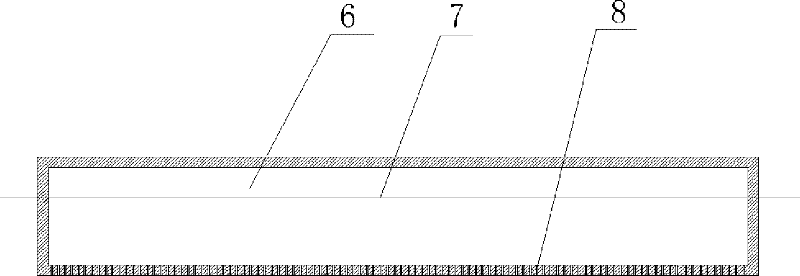

[0010] See figure 2 , image 3 , the improved coating roll device of the present invention, which includes a coating roll 1, a coil driving roll 4 and a driven roll 3, and the material (PET film) 2 contacts the coating roll 1 during the winding process, The front end of the driven roller 3 is provided with a static eliminator 5, and the static eliminator includes a hollow tube 6, and a plurality of through holes 8 are arranged on the hollow tube 6, and a metal wire 7 is arranged inside the hollow tube.

[0011] The two ends of the metal wire are connected to the power supply. After the wire is energized, the negative ions generated flow to the material 2 through the through hole 8 on the hollow tube 6, eliminating the static electricity generated when the material 2 passes through the driven roller 3, and ensuring the driving roller 4 The static electricity on the material (PET film) 2 passing through the coating roller 1 is eliminated during winding, preventing the static ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com