Multifunctional numerical control combined machine tool for machining shaft parts

A technology of combining machine tools and shaft parts, which is used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem that the production line is too long and cannot be processed and milled at both ends of the reference center hole of shaft parts at the same time. End face processing, different processing methods, etc., to achieve the effect of reducing the floor space and shortening the assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

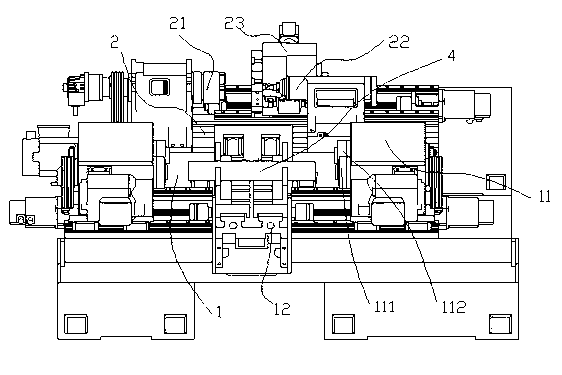

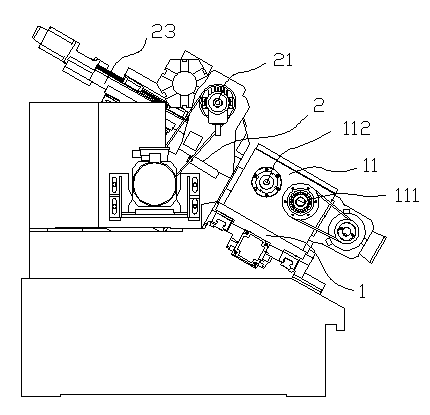

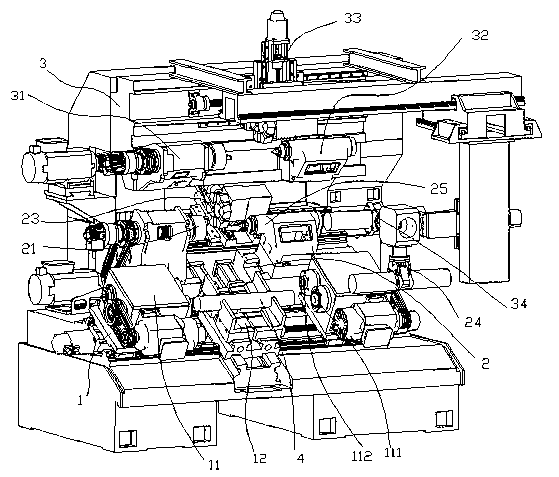

[0021] Such as figure 1 , 2 As shown in and 5, a multifunctional numerical control combined machine tool for processing shaft parts combined with two machine tools, the main work surface of the machine tool adopts a superimposed structure of two steps.

[0022] Wherein the first stepped surface 1 at the bottom is provided as an inclined plane, and the inclination of the inclined plane is 25°-45°. Both ends of the first stepped surface 1 are respectively provided with a spindle head 11 for milling the center hole of the end face. Each spindle head 11 is provided with a milling spindle 111 and a drilling spindle 112, which are respectively used for milling and drilling of the shaft 4. Center hole machining. A self-centering jig 12 is arranged in the middle of the first stepped surface 1 and can slide along the transverse sliding platform.

[0023] The second stepped surface 2 is an inclined surface hollowed out in the middle, and the second stepped surface 2 is set at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com