Aluminium electrolysis cell through-current body hot-line welding control system

A technology of aluminum electrolytic cell and control system, which is applied in the control field of aluminum electrolytic cell through-fluid non-stop welding, which can solve problems such as difficult operation, insignificant shielding effect, and easy magnetization of magnetic-conducting materials, and achieves good effect and high degree of automation High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

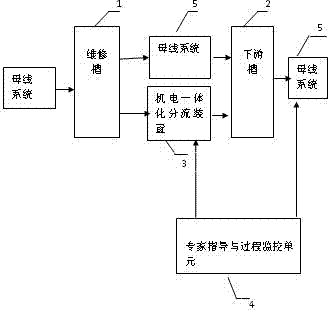

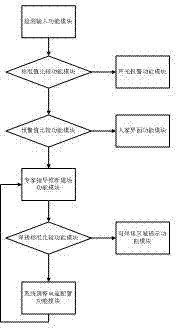

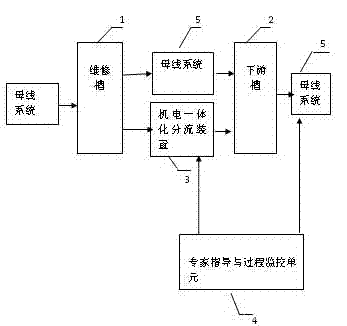

[0033] Example 1: When welding the cathode steel rod and the aluminum soft strip, a mechatronic shunt device 3 is installed between the maintenance tank 1 and the downstream tank 2, and the aluminum electrolytic tank passes the expert guidance and the process monitoring unit 4 to the maintenance tank 1 The temperature and current of the bus system 5 and the shunt device 3 and the bus system 5 of the downstream slot 2 are monitored online, and the current and temperature signals are input to the expert guidance and process monitoring unit 4 through the detection input function module, and the function module is compared with the standard value according to the standard value. The pre-set standard threshold range is compared with the warning threshold range. If the current or temperature data is not within the standard threshold range, the light and voice alarm will be issued through the sound and light alarm function module, and the detected The current and temperature data are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com