Chemical cleaning method for reverse osmosis membrane

A chemical cleaning and reverse osmosis membrane technology, which is applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of unsatisfactory operating time and service life of reverse osmosis membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

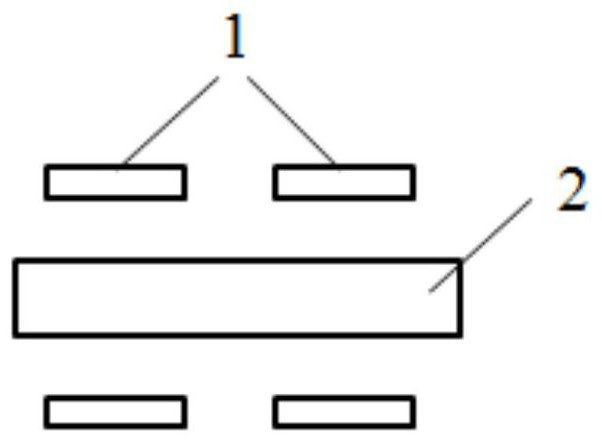

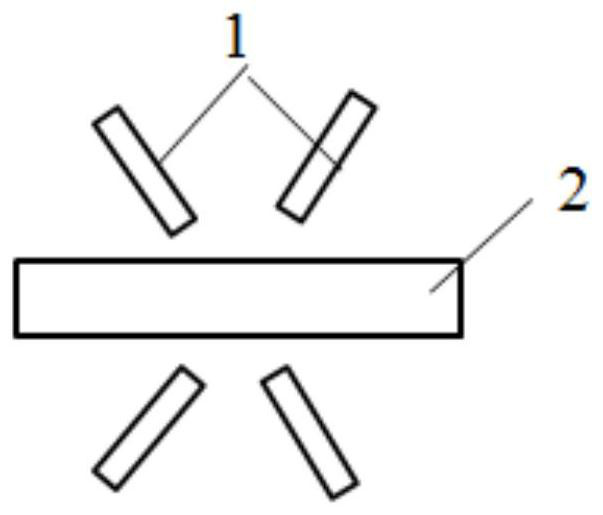

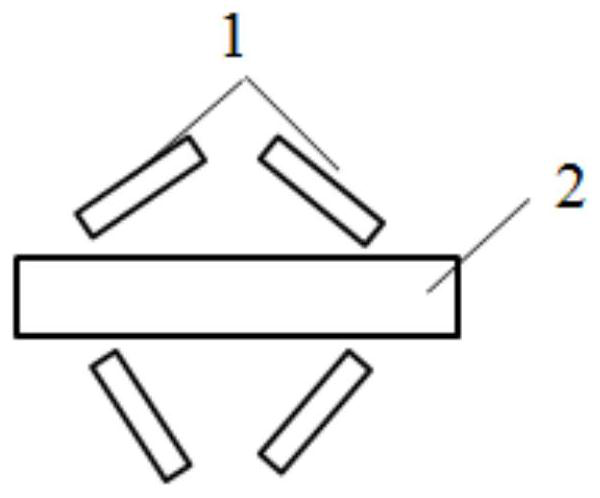

Image

Examples

Embodiment 1

[0055] The reverse osmosis membrane chemical cleaning method described in the present embodiment comprises the following steps:

[0056] (1) prepare reverse osmosis cleaning agent, the mass fraction of its raw material is: EDTA ammonium salt (ammonium ethylenediamine tetraacetate) 15%, chelating agent (ATMP Na 4 ) 5%, ethanolamine 3%, and the rest is water;

[0057] Prepare the bactericide, the mass fraction of its raw materials is: organic bromine (DBNPA) 10%, first auxiliary agent (lactic acid) 2%, solvent (polyethylene glycol) 60%;

[0058] Prepare an acid cleaning agent, the mass fraction of its raw materials is: citric acid 15%, organic phosphoric acid (hydroxyethylidene diphosphoric acid) 5%, and the rest is water;

[0059] Prepare an alkaline cleaning agent, the mass fraction of its raw materials is: EDTA disodium salt 15%, sodium dodecylsulfonate 1%, the second auxiliary agent (lactic acid) 2%, and the rest is water;

[0060] (2) preparation mass fraction is 30% hydr...

Embodiment 2

[0075] The reverse osmosis membrane chemical cleaning method described in this embodiment is the same as in Example 1, the difference is that the alkali cleaning process specifically includes the following steps:

[0076] (1) Use fresh alkali cleaning reagent prepared for the first time to clean the first section of reverse osmosis membrane components. The alkali cleaning time is 2 hours, and the ratio of reverse osmosis membrane area to alkali cleaning time is 26㎡ / min. At the same time, it is treated with ultrasonic oscillation The first reverse osmosis membrane module;

[0077] (2) Use the fresh alkali cleaning reagent prepared for the second time to clean the second and third reverse osmosis membrane components in series. The alkaline cleaning time is 2 hours, and the ratio of the reverse osmosis membrane area to the alkaline cleaning time is 18.5㎡ / min. At the same time, it cooperates with ultrasonic oscillation to process the second and third reverse osmosis membrane compo...

Embodiment 3

[0081] The chemical cleaning method for the reverse osmosis membrane described in this embodiment is the same as that of Embodiment 2, the difference is that the step of washing and cleaning the water tank is included before the pickling step:

[0082] (1) Observation: Fill the cleaning water tank with water and observe the clarity of the water in the water tank. If the water is turbid, it needs to be washed;

[0083] (2) Open the steam inlet valve of the cleaning water tank, heat the water in the cleaning water tank to 25°C, shake the cleaning water tank, and discharge the water in the cleaning water tank after washing;

[0084] (3) Fill water again and repeat the operation of step (2) until the water in the cleaning water tank is clear.

[0085] The difference is also that in the pickling step, after the pickling reagent has cleaned all the reverse osmosis membrane components, it circulates back to the cleaning water tank, and after detecting the pH value, it is used to clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com