Antioxidation graphite sealing ring

A graphite sealing and anti-oxidation technology, which is applied in the field of solar thermal utilization, can solve the problems that graphite sealing rings cannot meet the use requirements and application restrictions, and achieve the effects of retaining self-lubricating performance, improving grinding efficiency, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

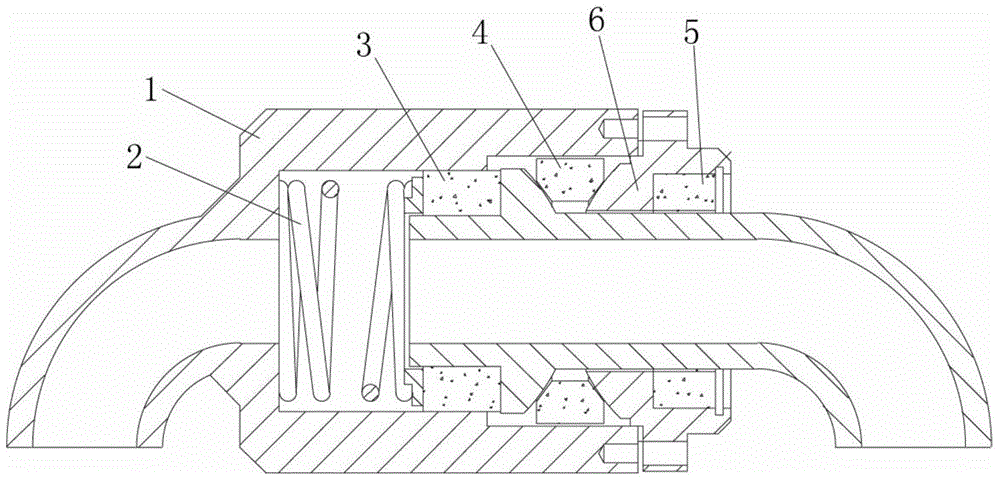

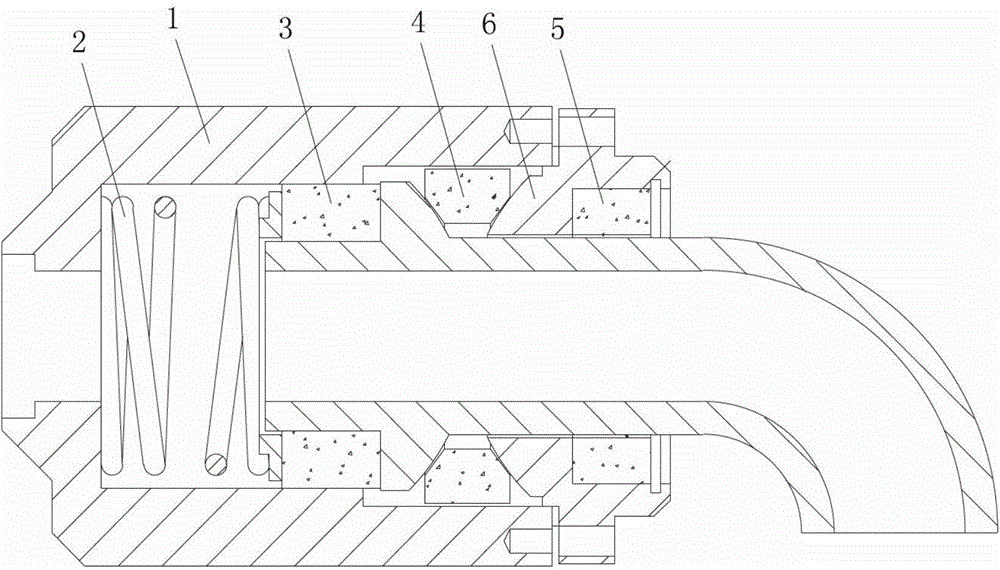

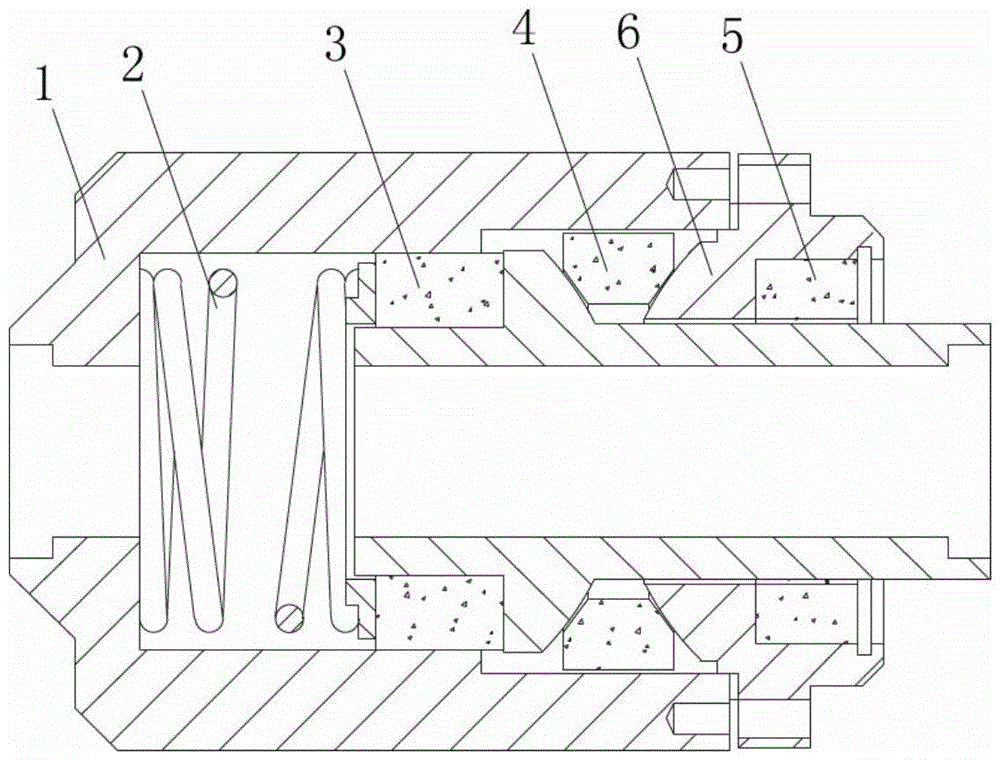

Image

Examples

Embodiment 1

[0022] An oxidation-resistant graphite sealing ring is prepared according to the following steps:

[0023] (1) Weigh each component according to the mass parts: 15 parts of silicon powder, 8 parts of boron carbide, 65 parts of asphalt, 8 parts of graphite, and 5 parts of tetrahydrofuran;

[0024] (2) Mix and stir the graphite, silicon powder, boron carbide and asphalt weighed in step (1), add tetrahydrofuran, and then quickly add it to the ball mill tank for ball milling for 50 hours. After the ball milling, vacuum distillation treatment, vacuum distillation After the treatment is completed, the mixture is added to the mold, heat-treated at 2000°C and pressed into a tube, and the tube is impregnated with polycarbosilane under high pressure at a pressure of 0.8MPa, and then pressurized and roasted to shape. After the shape is completed, it is cut into rings and polished.

Embodiment 2

[0026] An oxidation-resistant graphite sealing ring is prepared according to the following steps:

[0027] (1) Weigh each component according to the mass parts: 12 parts of silicon powder, 5 parts of boron carbide, 70 parts of asphalt, 5 parts of graphite, and 3 parts of tetrahydrofuran;

[0028] (2) Mix and stir the graphite, silicon powder, boron carbide and asphalt weighed in step (1), add tetrahydrofuran, and then quickly add it to the ball mill tank for ball milling for 50 hours. After the ball milling, vacuum distillation treatment, vacuum distillation After the treatment is completed, the mixture is added to the mold, heat-treated at 2000°C and pressed into a tube, and the tube is impregnated with a high-pressure polymer impregnating agent at a pressure of 0.8 MPa, and then pressurized and roasted to shape. After the shape is completed, it is cut into rings and polished. .

Embodiment 3

[0030] An oxidation-resistant graphite sealing ring is prepared according to the following steps:

[0031] (1) Weigh each component according to the mass parts: 8 parts of silicon powder, 10 parts of boron carbide, 68 parts of asphalt, 12 parts of graphite, 2 parts of tetrahydrofuran;

[0032] (2) Mix and stir the graphite, silicon powder, boron carbide and asphalt weighed in step (1), add tetrahydrofuran, and then quickly add it to the ball mill tank for ball milling for 50 hours. After the ball milling, vacuum distillation treatment, vacuum distillation After the treatment is completed, the mixture is added to the mold, heat-treated at 2000°C and pressed into a tube, and the tube is impregnated with a high-pressure polymer impregnating agent at a pressure of 0.8 MPa, and then pressurized and roasted to shape. After the shape is completed, it is cut into rings and polished. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com