Double-layer crucible used for Czochralski silicon single crystal growth

A double-layer crucible, Czochralski technology, applied in the direction of single crystal growth, crystal growth, self-melting liquid pulling method, etc., can solve the problems of large equipment investment, electromagnetic field consumption, etc., to reduce oxygen concentration and improve temperature stability , the effect of reducing the erosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

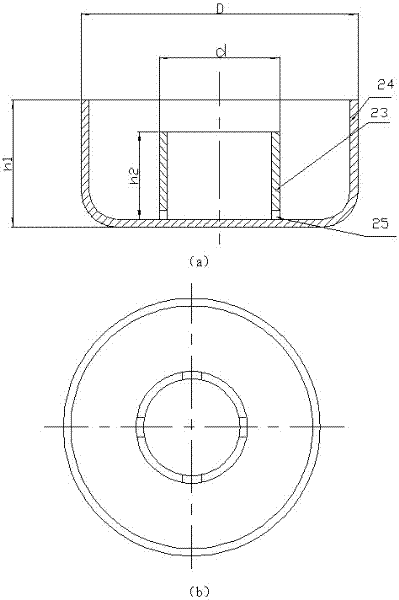

[0012] like figure 1 As shown, the double-layer crucible used for the growth of Czochralski silicon single crystal includes a crucible 24, an inner crucible ring 23, and a liquid flow hole 25. The crucible 24 is provided with a crucible inner ring 23 in the center, and the lower end of the crucible inner ring 23 is connected to the bottom of the crucible 24. Four symmetrically distributed liquid flow holes 25 are arranged at the contact point, the diameter of the flow liquid holes 25 is 10-20 mm, the crucible inner ring 23 is coaxial with the crucible 24, and the wall thickness of the crucible 24 and the crucible inner ring 23 is 8-12 mm, The ratio of the outer diameter d of the crucible inner ring 23 to the outer diameter D of the crucible 24 is 0.5-0.7, and the height h of the crucible inner ring 23 2 Height h with crucible 24 1 The ratio is 0.6 to 0.8.

[0013] The materials of the crucible 24 and the crucible inner ring 23 are quartz glass, silicon nitride ceramics or si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com