Semi-inverse construction method of cyclone well

A construction method and a technology of semi-reverse work, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as high geological conditions and construction site requirements, surrounding soil subsidence, and hidden safety hazards of surrounding buildings, saving manpower, The effect of reducing project cost and ensuring safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

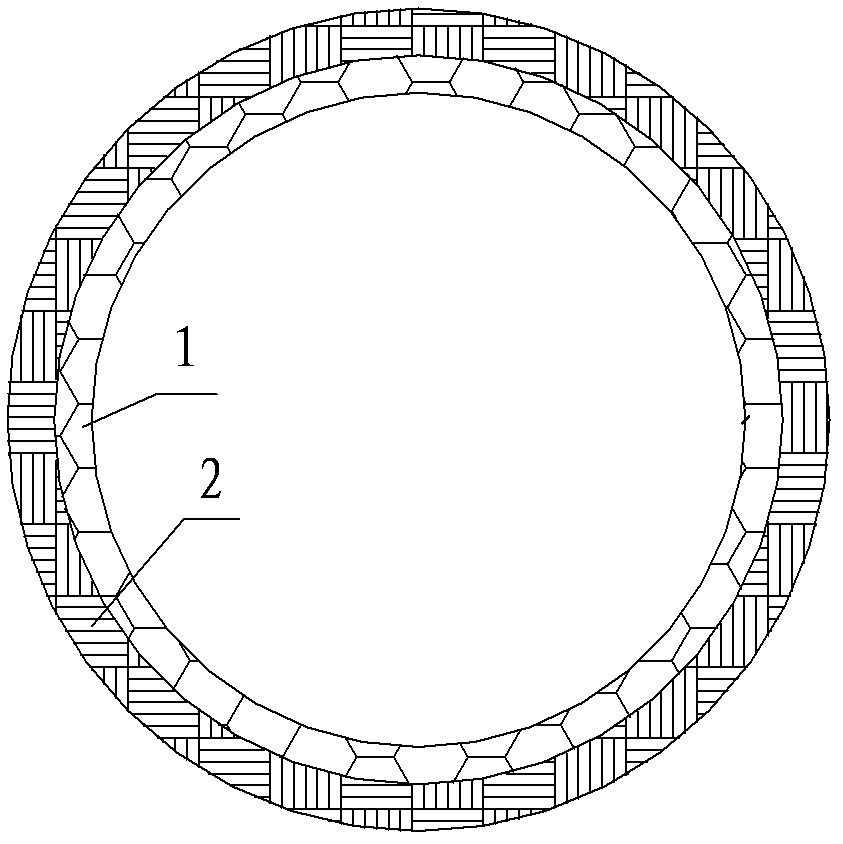

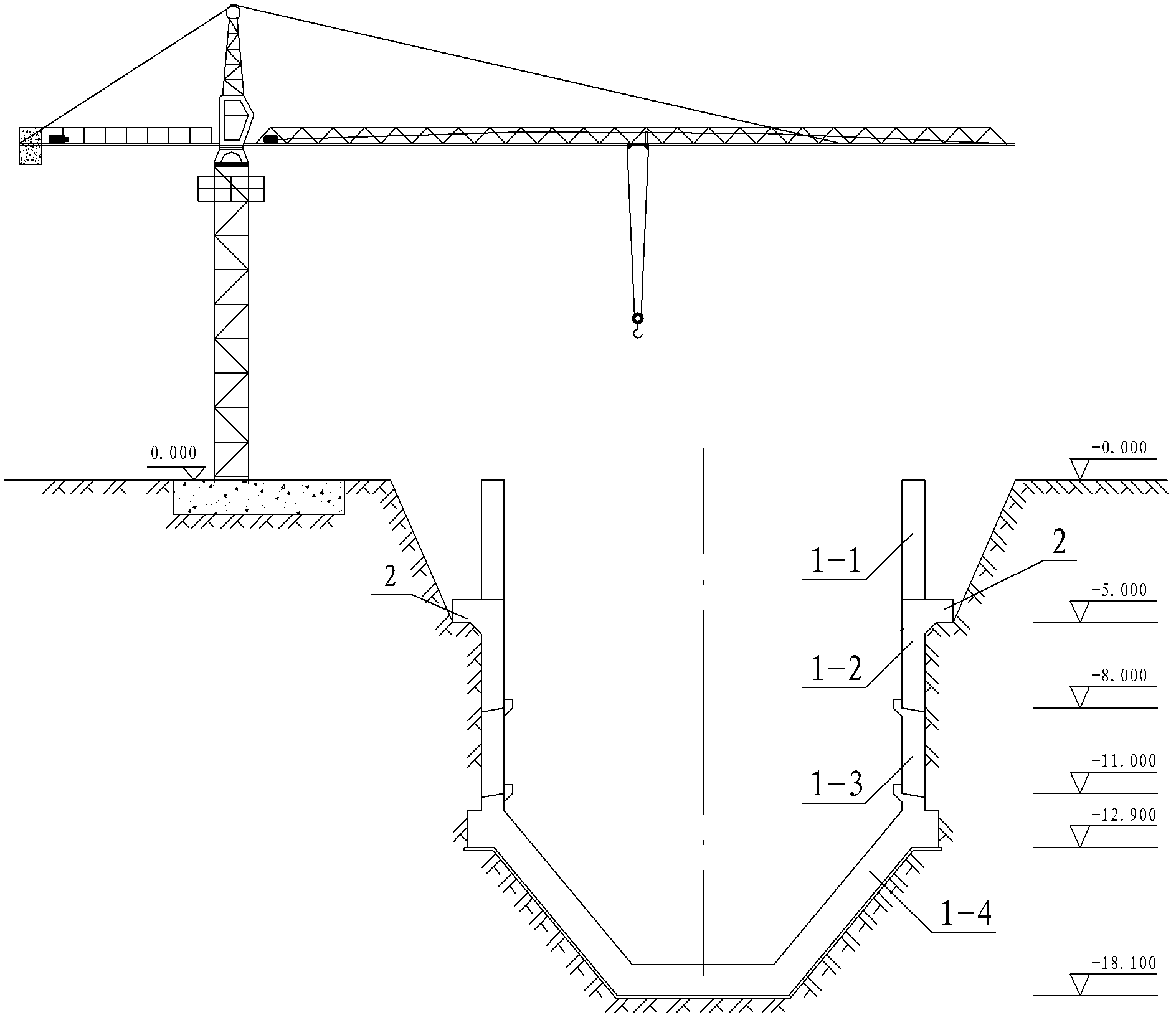

[0032] The continuous casting machine swirl pool of Hebei Jingye 150t converter phase II project is located between the 13th and 14th lines of the BC span of the newly built main building, close to the main building column foundation, and the depth reaches -18.100m, according to the actual situation on site and the overall progress of the project , it was decided that the outer wall of the shaft should be constructed using the semi-inverted construction method.

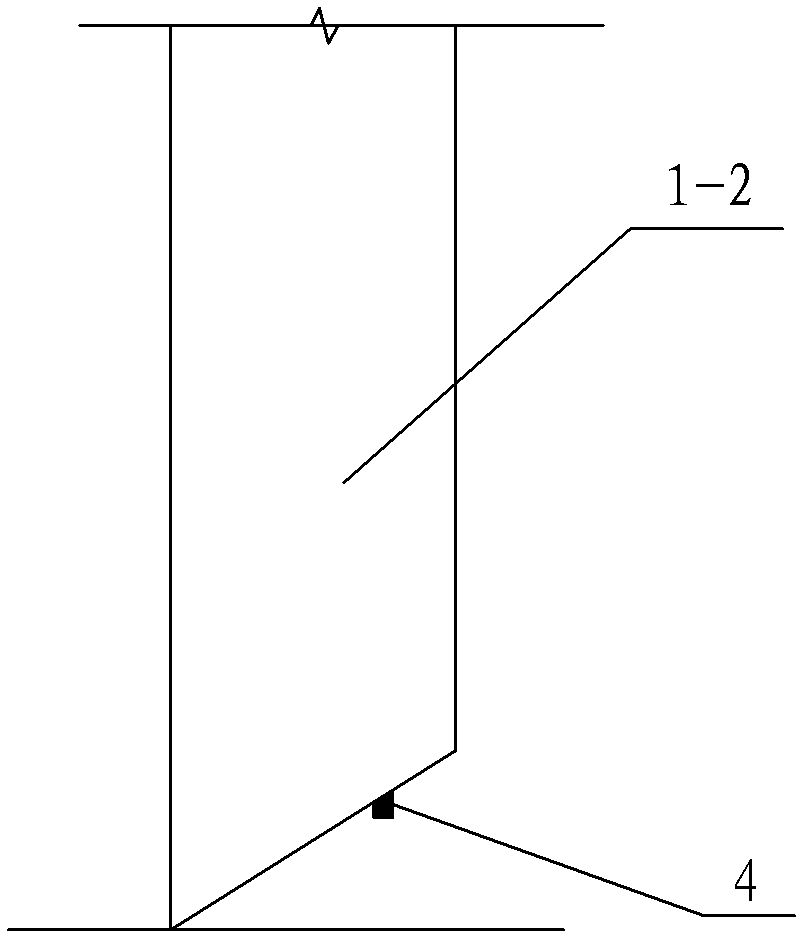

[0033] See Figure 1 to Figure 6 .

[0034] The above-mentioned swirl well semi-reverse construction method comprises the following steps:

[0035] 1) Measurement and positioning, determine the position of the center point of the swirl well, the well wall 1 and the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com