Method for realizing flat turning and watering of double-walled steel cofferdam by utilizing air bags

A technology of double-walled steel cofferdam and cofferdam, which is used in construction, infrastructure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

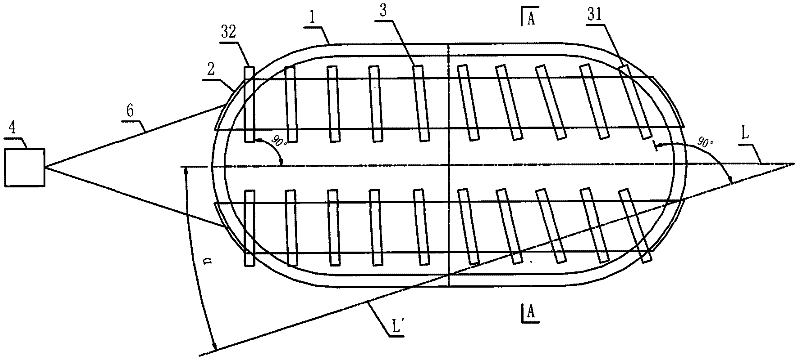

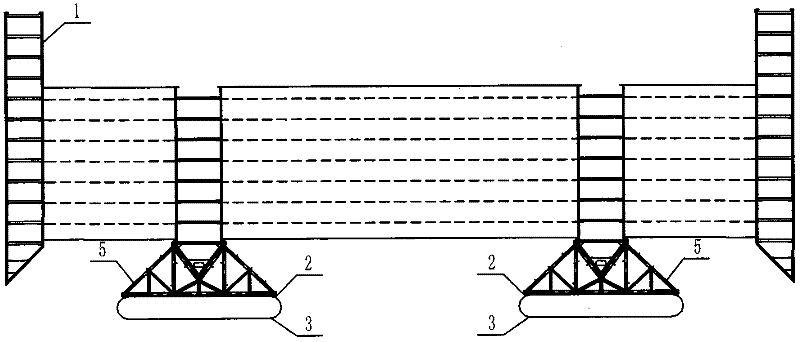

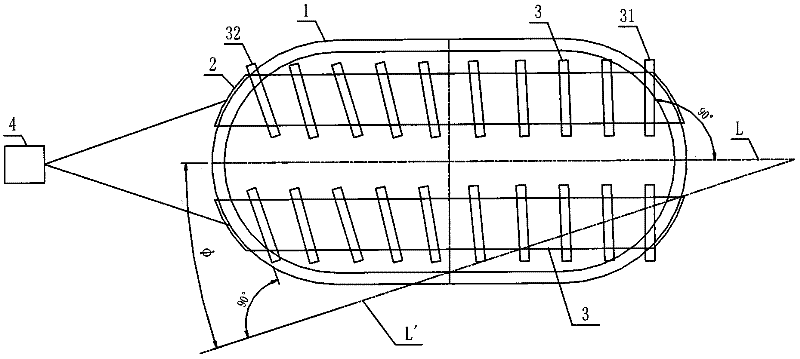

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the method for realizing double-walled steel cofferdams to turn horizontally down the river by means of the air bag described in the present method comprises the following steps:

[0022] 101. Arrange at least two pallets 2 under the cofferdam 1, arrange N (N≥1) airbags 3 under each pallet 2, and arrange N airbags 3 in a row under each pallet 2. Wherein, the lower part of the cofferdam 1 is connected to the supporting frame 5 by bolts, the supporting plate 2 is arranged below the supporting frame 5, and the supporting plate 2 and the airbag 3 jointly form the glide path of the cofferdam 1.

[0023] 102. If Figure 4 , D is the sideline of obstacles encountered by the cofferdam 1 going down the river. When it is necessary to turn the angle α to go down the river, the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com