Construction method for wood formwork with bigger circular structure by taking reinforcing steel bar as lateral rear edge

A technology of horizontal back corrugation and construction method, which is applied in the connection parts of formwork/template/work frame, formwork/template member, building structure, etc. , waste of resources and other issues, to achieve significant economic and social benefits, simple and easy construction methods, and reduce consumption and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the drawings and embodiments:

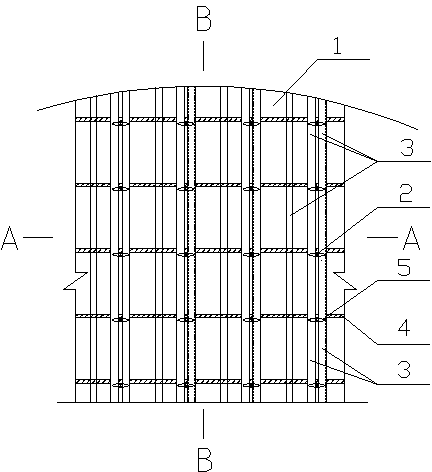

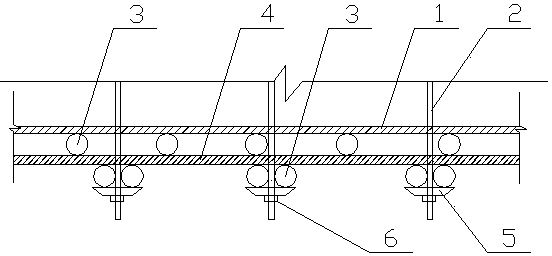

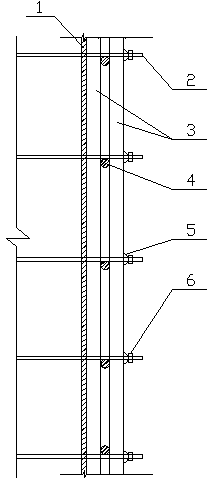

[0041] In the attached drawing: wooden formwork 1, opposite tension bolt 2, longitudinal back flute 3, transverse back flute 4, mountain clamp 5, nut 6.

[0042] For this embodiment, see attached figure 1 Attached Figure 19 ; The construction method of circular structural timber formwork with steel bars as the transverse back corrugation, the steps are as follows:

[0043] Process the size of the wooden template 1 according to the size of the circular structure;

[0044] Drill holes on the wooden template 1 according to the spacing of the tension bolts 2 to be installed, and the spacing of the tension bolts 2 is determined according to the side pressure and dumping pressure of the concrete poured on the construction wall and the on-site template support parameters;

[0045] According to the size of the drawing, determine the position of the inner and outer sides of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com