Ram concrete pump and its pumping control system

A control system and concrete pump technology, applied in the field of hydraulic machinery, can solve problems such as pumping operation can not be carried out normally, pipe blockage, etc., to prevent the descending speed from being too slow, avoid pipe blockage problems, and improve adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

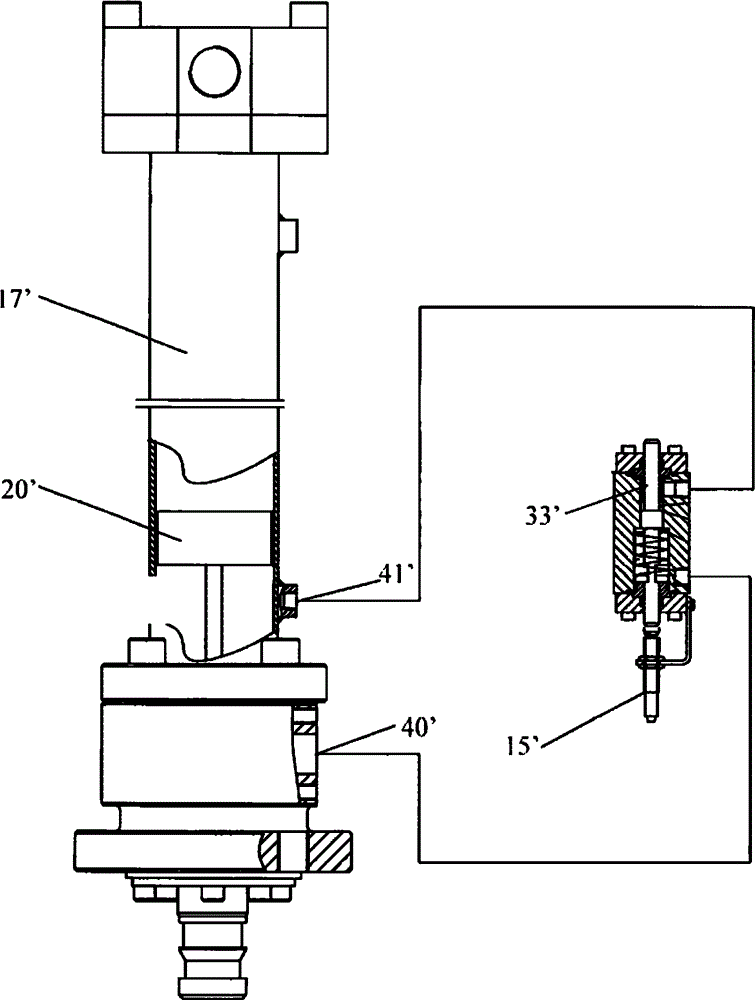

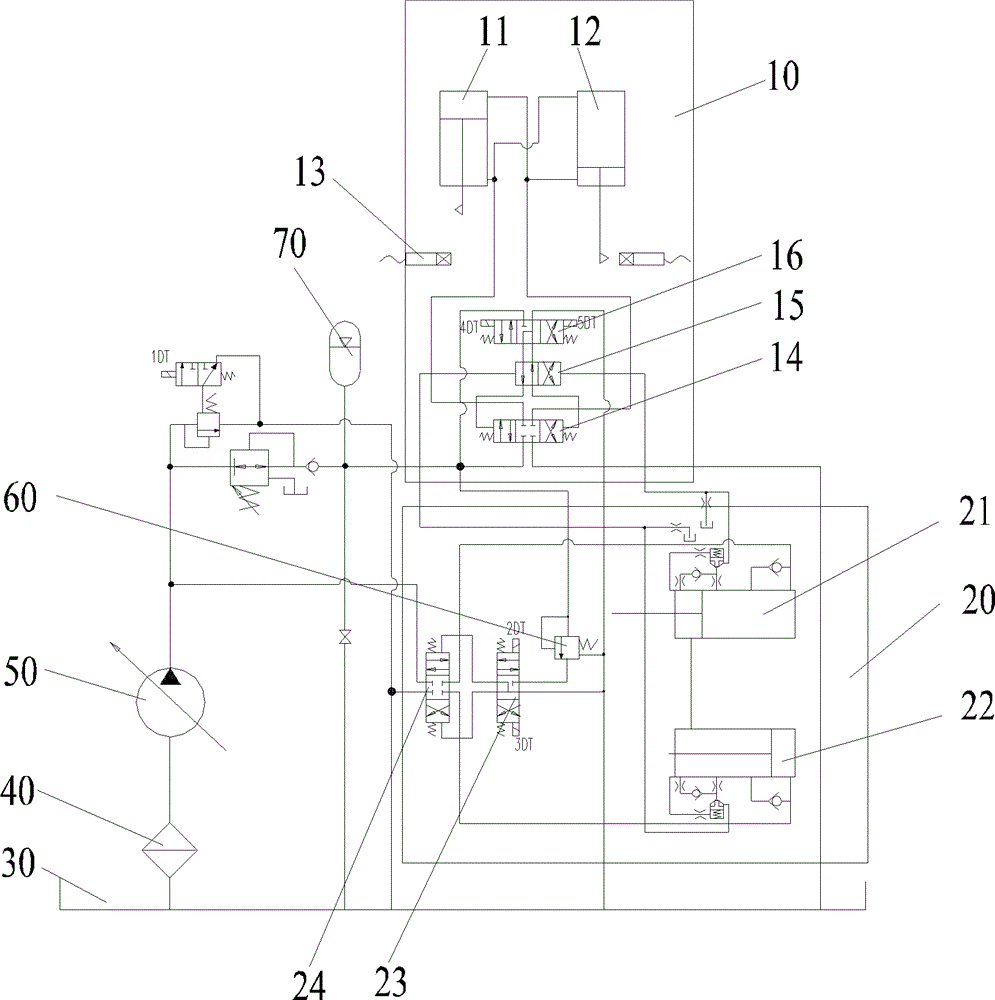

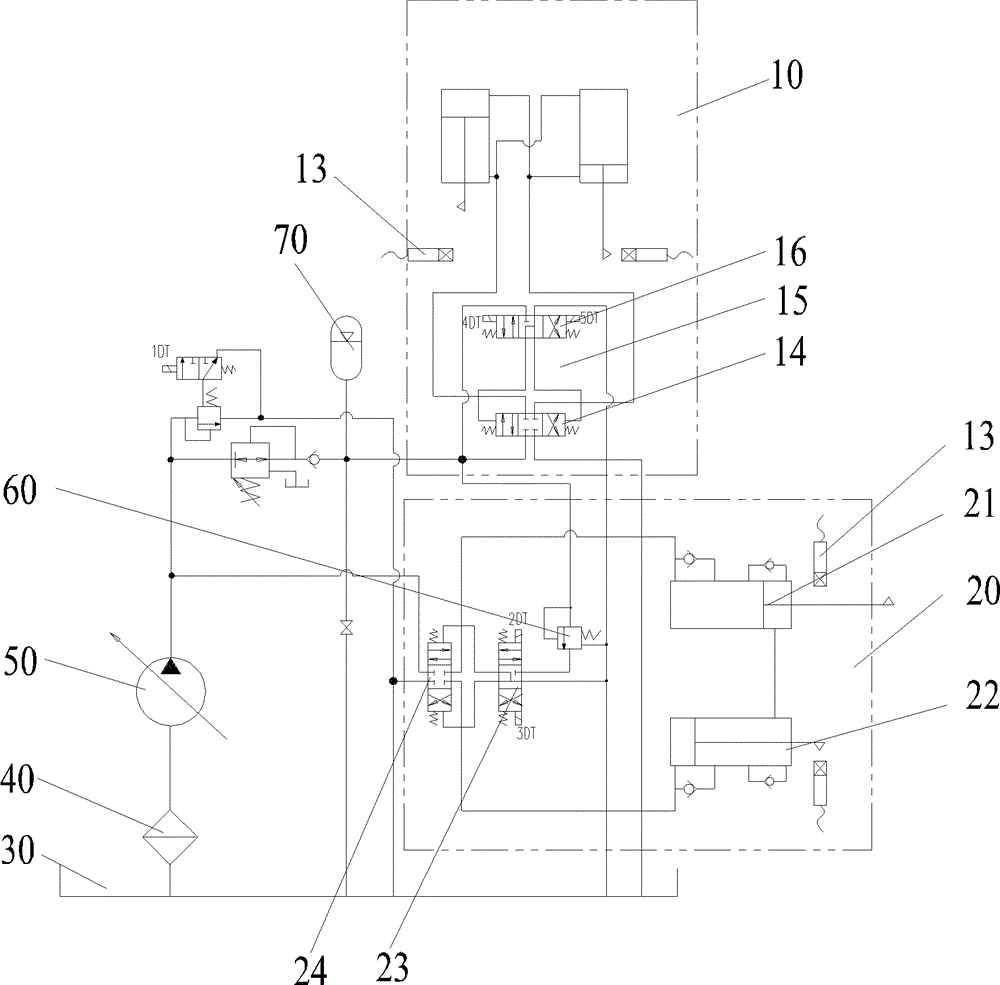

[0018] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0019] Such as figure 2 As shown, according to the first embodiment of the present invention, the pumping control system of the ram type concrete pump includes a hydraulic oil supply system, a ram control system 10 and a main cylinder control system 20, and the hydraulic oil supply system connects the oil circuit and the ram respectively The control system 10 is connected with the master oil cylinder control system 20, and provides the pressure oil required for the two systems to work.

[0020] The hydraulic oil supply system includes an oil tank 30, the oil tank 30 is connected to the main pump 50 through the oil circuit, and a filter 40 is arranged between the main pump 50 and the oil tank 30 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com