Removable horizontal glue removing furnace for hard alloy production

A cemented carbide and horizontal furnace technology, which is applied in the field of movable horizontal debinding furnace for cemented carbide production, which can solve the problems of large changes in carbon content of the upper and lower laminated blocks, large deviation of alloy performance, easy deformation and brittle fracture, etc. problem, to achieve uniform oxygen content and carbon content, long service life, and reduce the effect of wiring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

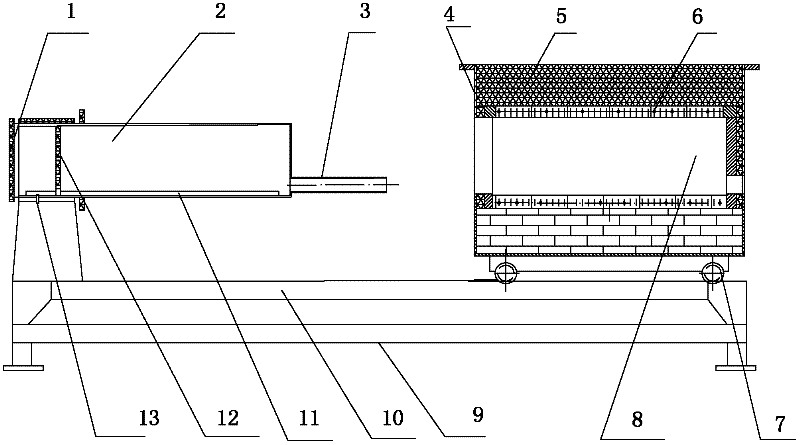

Method used

Image

Examples

Embodiment 1

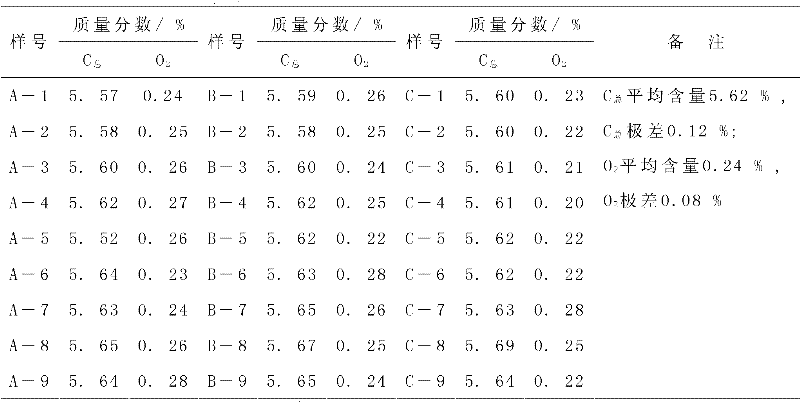

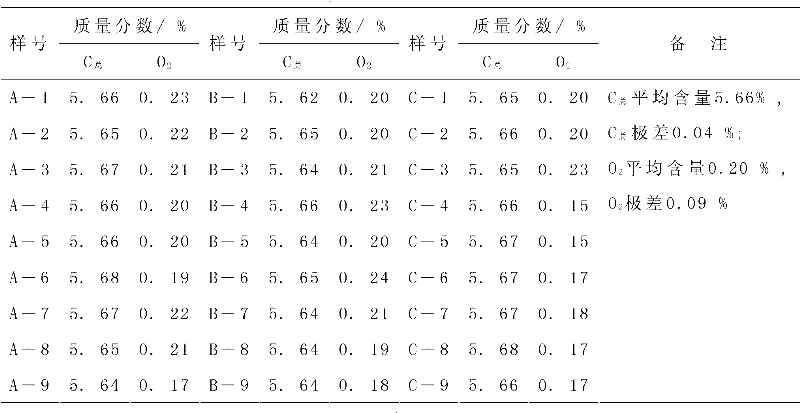

[0014] Example 1: Carbon and oxygen content of compact after debinding

[0015] Table 1 and Table 2 are the carbon and oxygen analysis results of the YJG8C brand compact after debinding by the air-cooled horizontal debinding furnace and the movable horizontal debinding furnace respectively.

[0016] It can be seen from Table 1 and Table 2 that after debinding by the movable horizontal debinding furnace, the range of carbon content of each boat compact is small, and the oxygen content is low, which is mainly due to the use of the movable horizontal debinding furnace. There are six temperature control zones, so that the temperature difference between the upper and lower parts of each group of green compacts is small. In addition, when the hydrogen gas is passed into the furnace, small hole pipes and filter plates 11 are used to divert the flow, so that the hydrogen gas can pass through the surface of each green compact evenly, ensuring The rubber is completely discharged, so tha...

Embodiment 2

[0021] The physical and mechanical properties of the alloy after embodiment 2 vacuum sintering

[0022] Table 3 and Table 4 respectively show the physical and mechanical properties of the compact after debinding in the air-cooled horizontal debinding furnace and the movable horizontal debinding furnace, and the alloy after vacuum sintering.

[0023] Since the total carbon content and oxygen content of the green compact are well controlled during debinding by the movable horizontal debinding furnace, the properties of the sintered alloy are better.

[0024] Table 3 Physical and mechanical properties of YG8C alloy after air-cooled furnace discharge and vacuum sintering

[0025]

[0026] Table 4 Physical and mechanical properties of YG8C alloy after movable grate glue and vacuum sintering

[0027]

Embodiment 3

[0028] Embodiment 3 Stove structure characteristic comparison

[0029] It can be seen from the introduction of the above-mentioned equipment structure that the new furnace type can naturally cool the furnace chamber loaded with green compacts by sealing the resistance wire connection device, increasing the heat preservation effect of the furnace, and adopting a mobile heating device. At the same time, the blasting of the blower during air cooling is omitted, so the required electric energy for cooling decreases. Therefore, when the amount of deglue compacted is the same, the design power of the new furnace type is reduced from the original 50kW to 36kW, which can save energy by about 20%. In addition, when the air-cooled debinding furnace is cooled by a blower, the resistance wire is cooled rapidly in a short period of time, the resistance wire is easily deformed and brittle, and the service life is short; while the new furnace type will move the heating device installed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com