Load sensor

A load sensor, ring-shaped technology, applied in the field of sensors, can solve the problems of affecting the measurement accuracy of the sensor, permanent deformation of the elastic body, and inconvenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

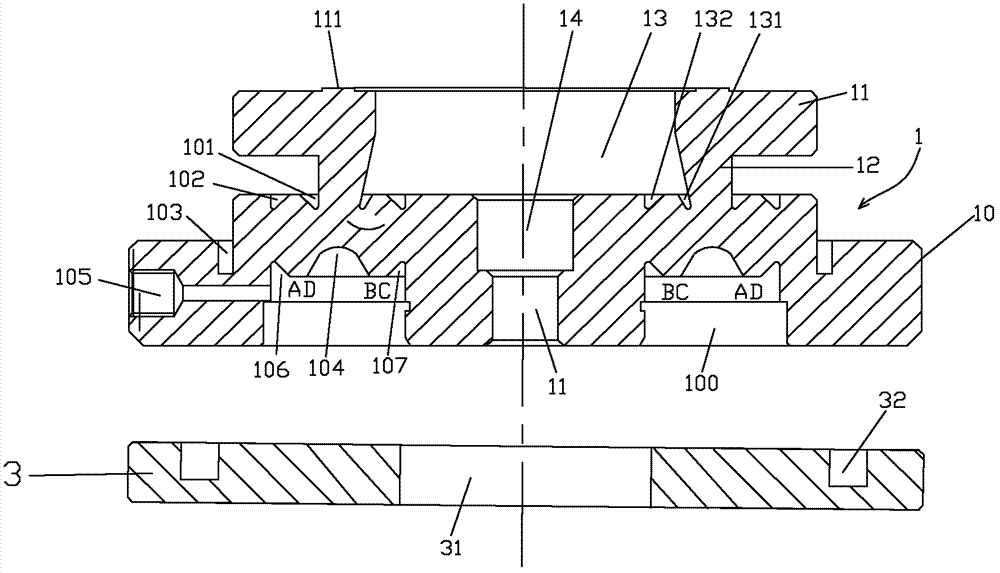

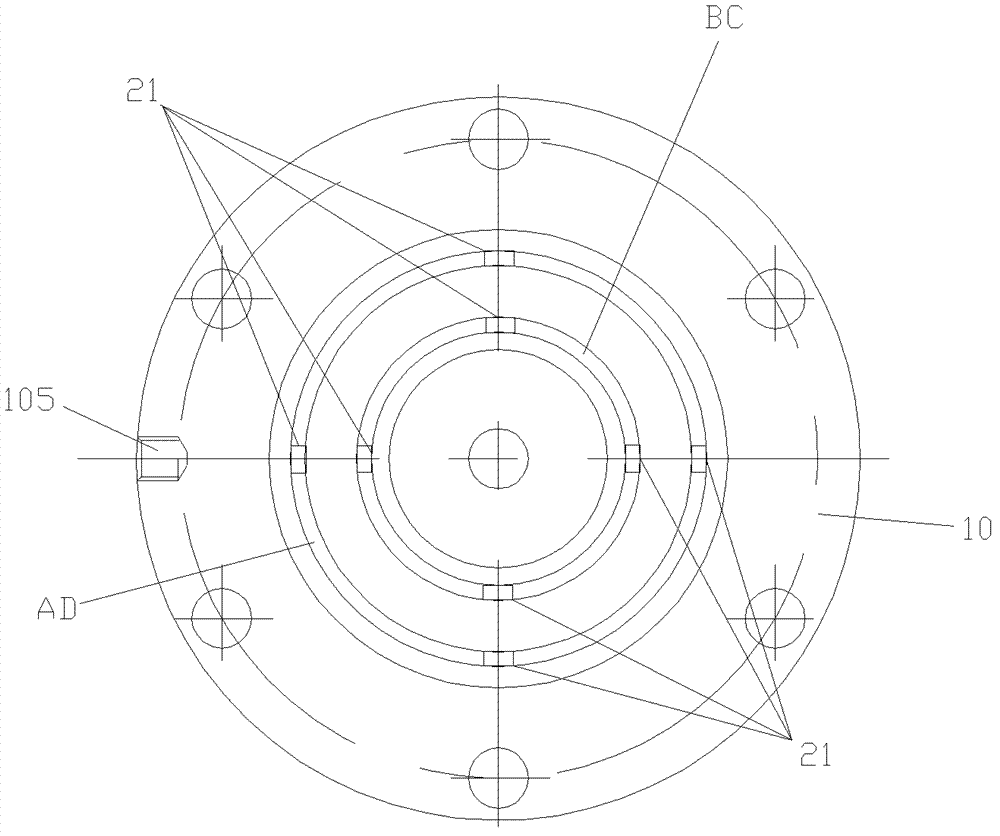

[0023] See figure 1 with 2 , The embodiment of the present invention is provided with a stressed elastic body 1, a strain gauge group (composed of 8 strain gauges 21) and a bottom cover 3.

[0024] The stressed elastic body 1 is provided with central through holes 13, 14 and 11, and the central through holes 13, 14 and 11 are coaxial central through holes with upper and lower steps. The force-receiving elastic body 1 is sequentially provided with a coaxial force-receiving platform 11, a force guiding column 12 and a stepped base 10 from top to bottom. The force platform 11 is provided with an annular force plane 111, and the bottom surface of the central through hole 13 is provided with a first annular force guide angle 131 extending obliquely downward along the bottom of the inner wall of the force guide column 12 and a first annular force guide angle located at the first annular force guide angle. The second annular force guiding angle 132 next to 131, the first annular force g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com