Method of manufacturing an assembly comprising a plurality of blades mounted in a platform

A blade and component technology, which is applied to the manufacturing field of fixed integral blisks, can solve problems such as being unsuitable for manufacturing large-sized metal parts, and achieve the effect of simple positioning steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

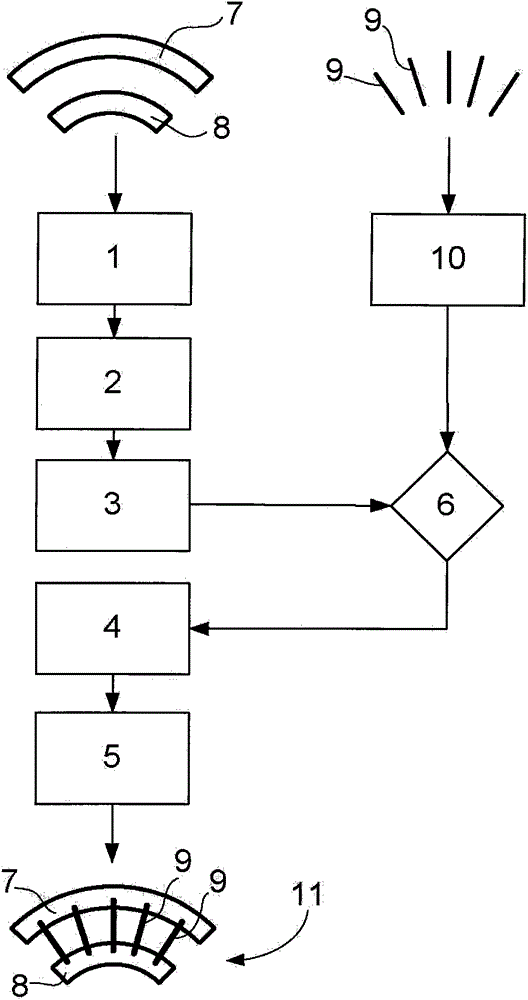

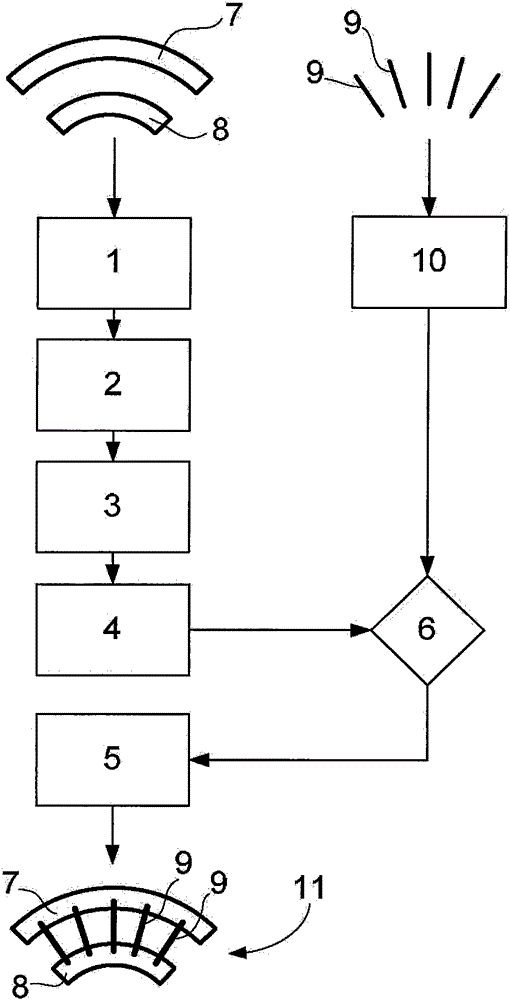

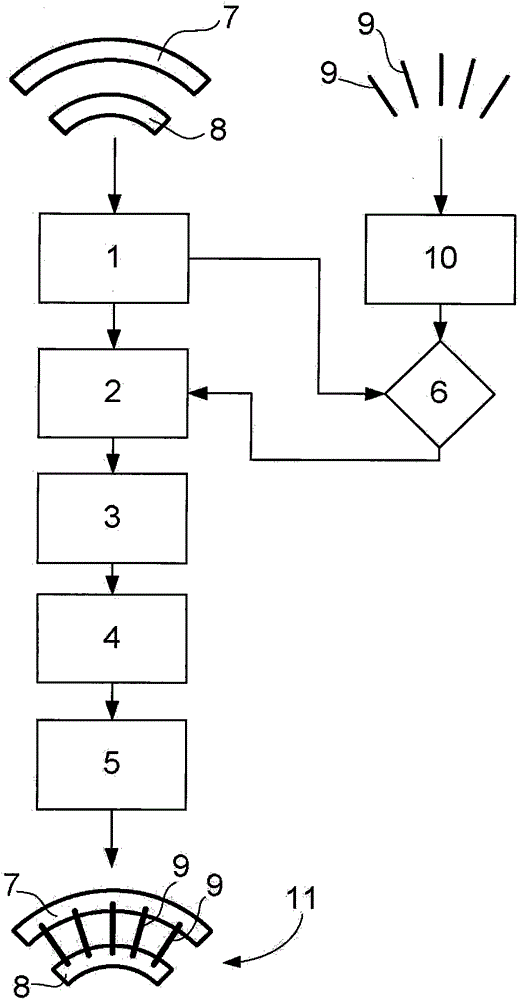

[0047] An integral blisk, such as a stator guide vane assembly of a turbojet compression stage, is conventionally formed from a plurality of blades held between an annular outer platform and an annular inner platform. The stator guide vane assembly blisk is divided into angular segments which are manufactured separately and joined together to form the stator guide vane assembly disc after installation in a turbojet compression stage.

[0048] refer to figure 1 , each stator guide vane assembly segment 11 comprises a plurality of vanes 9 fixed at their radially inner ends to an annular inner platform portion 8 (known as inner platform section 8) and at their radially outer ends to an annular outer platform Section 7 (outer platform section 7).

[0049] Refer again figure 1 , according to the first embodiment of the manufacturing method of the present invention, the platform sections 7, 8 are manufactured by Metal Injection Molding (MIM) method, in which fine alloy (nickel, ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com