Automatic doffer for ring spinning machine

A ring spinning and doffing machine technology, applied in textiles and papermaking, etc., can solve the problems of lower production efficiency, low yarn pulling speed, and difficult detection of doffing and missing yarn, so as to improve yarn pulling efficiency and reduce radial The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

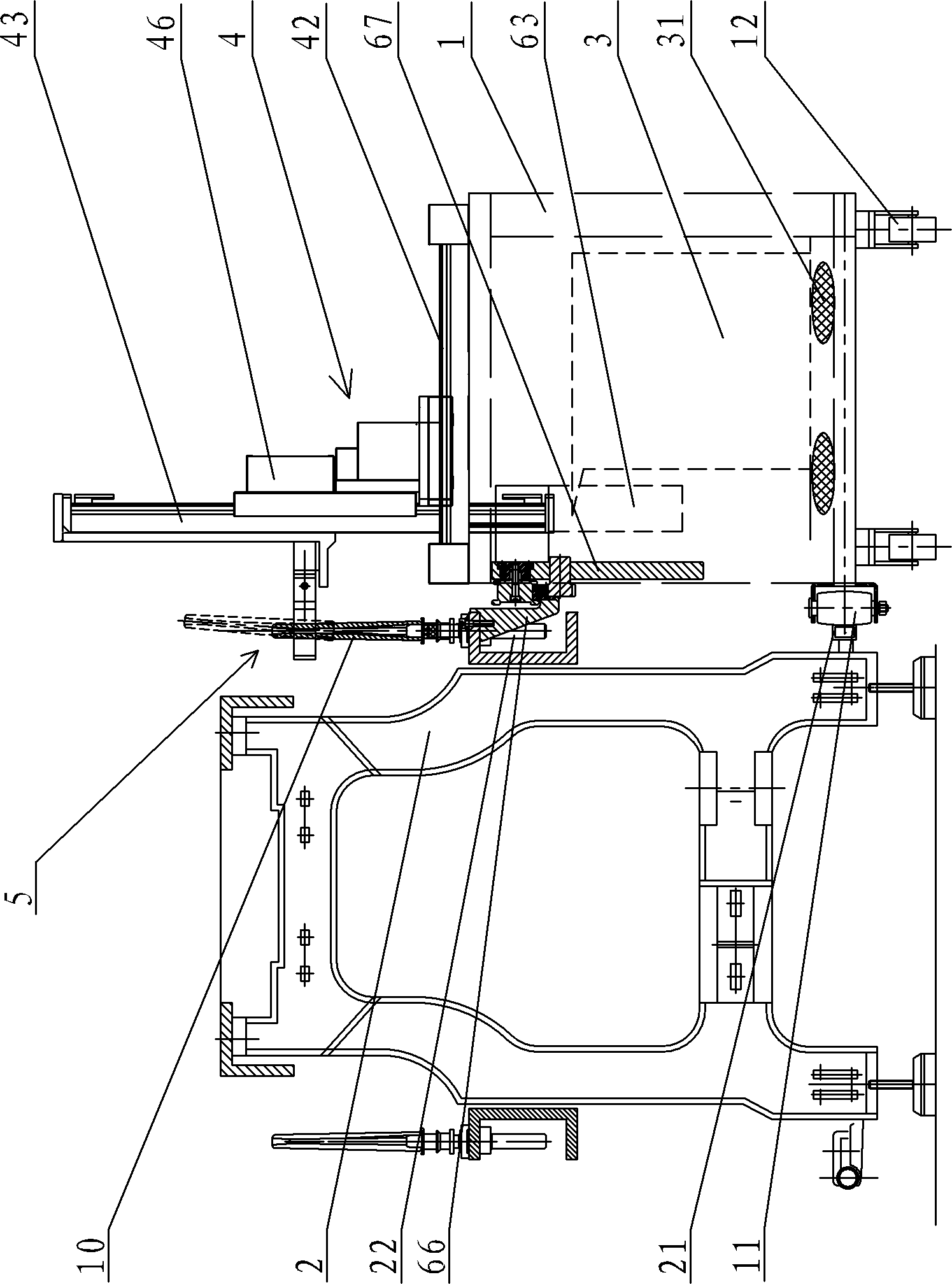

[0041] Such as figure 1 As shown, the ring spinning intelligent doffing machine of the present invention includes a doffing car 1, a yarn connecting basket 3 is installed in the doffing car 1, and a shockproof pad 31 is arranged between the bottom of the yarn connecting basket 3 and the doffing car 1, for Buffer the impact on the doffing carriage 1 when the bobbin 10 falls. The doffing trolley 1 is installed on one side of the ring spinning frame 2 through a sliding device, and the sliding device is used to make the doffing trolley 1 move in parallel along the length direction of the ring spinning frame 2 . The doffing trolley 1 is also equipped with two friction wheels 11 near the side of the ring spinning frame 2, and the friction wheels 11 are in contact with the auxiliary track 21 installed on the bottom of the ring spinning frame 2. The side of the bottom of the doffing trolley 1 away from the ring spinning machine 2 is equipped with a universal wheel 12 . A three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com