Liquid crystal display device and method for manufacturing transparent electrode

A technology of liquid crystal display devices and transparent electrodes, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of high off-state transmittance, disordered orientation of liquid crystal molecules 8a, and decreased contrast, so as to suppress light leakage and disorder , to improve the effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

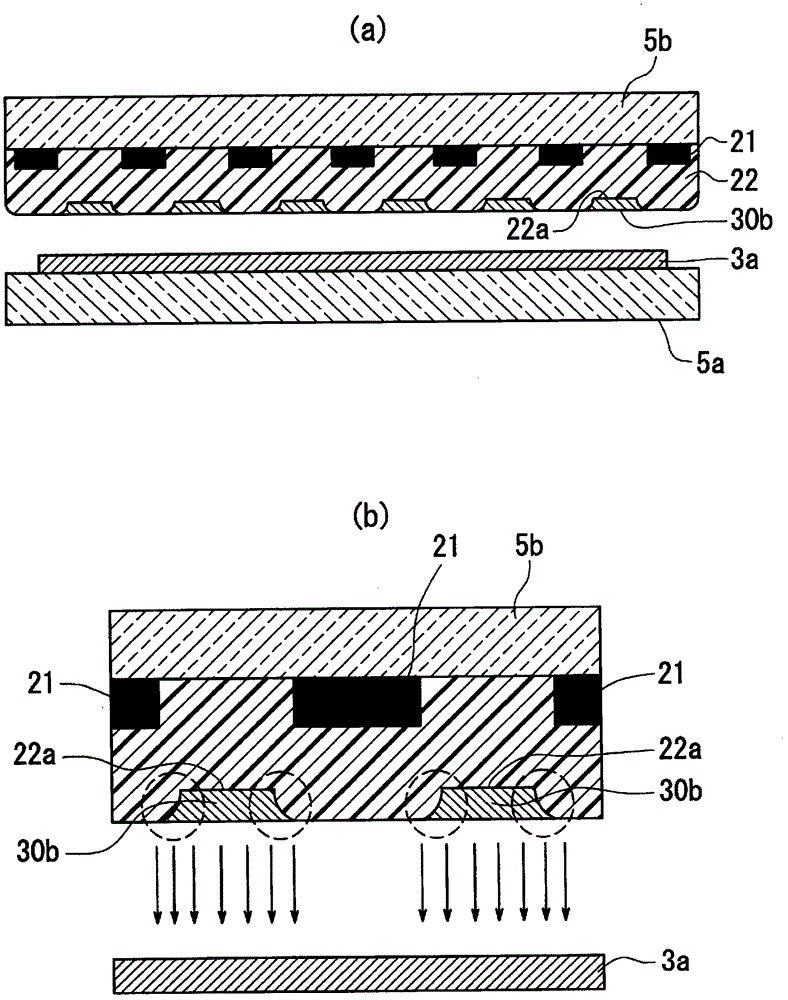

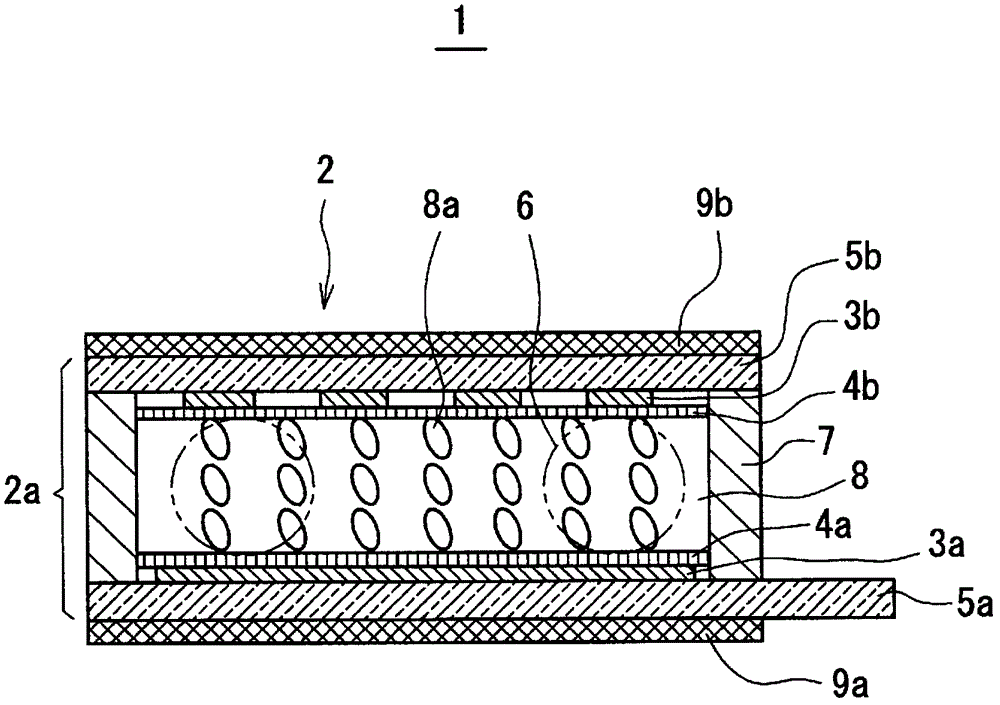

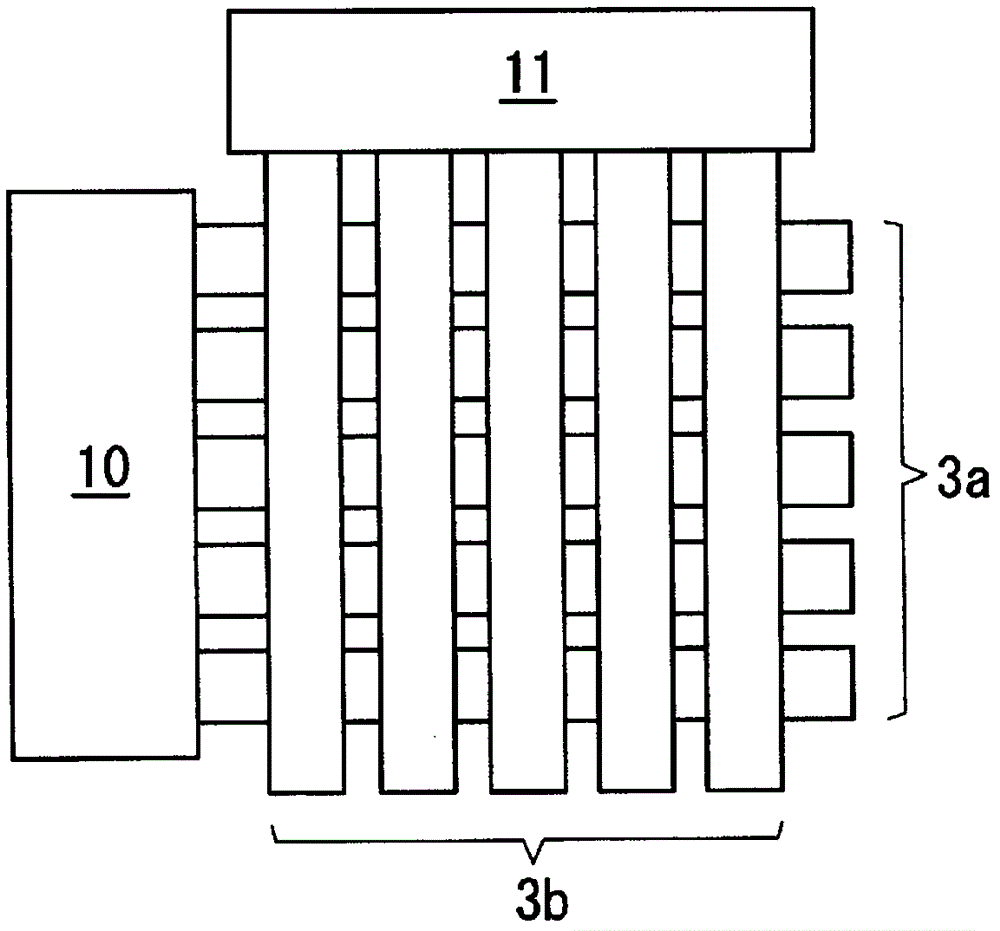

[0038] Below, refer to figure 1 Embodiments of the present invention will be described. figure 1 It is a schematic cross-sectional view showing a liquid crystal display device having a simple matrix electrode structure of the present invention, (a) is a schematic cross-section showing the shape of the first and second strip-shaped transparent electrodes, and (b) is a schematic cross-sectional view showing the shape of the first and second strip-shaped transparent electrodes. A schematic cross-sectional view of an electric field generated by an off-state voltage applied between the first and second transparent electrodes. In addition, in figure 1 The display device shown in is characterized by the structure of the second transparent electrode and its manufacturing method, and other structures and Figure 4 The vertical alignment type liquid crystal display devices shown in are the same, and therefore the same reference numerals are attached to the same structural parts, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com