Process hot air circulating device for tobacco charging machine and control method for device

A technology of hot air circulation and control method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of low thermal efficiency of radiators, short service life of radiators, unable to reach the temperature of process hot air, etc., so as to improve heat exchange efficiency and reduce Warm-up time, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

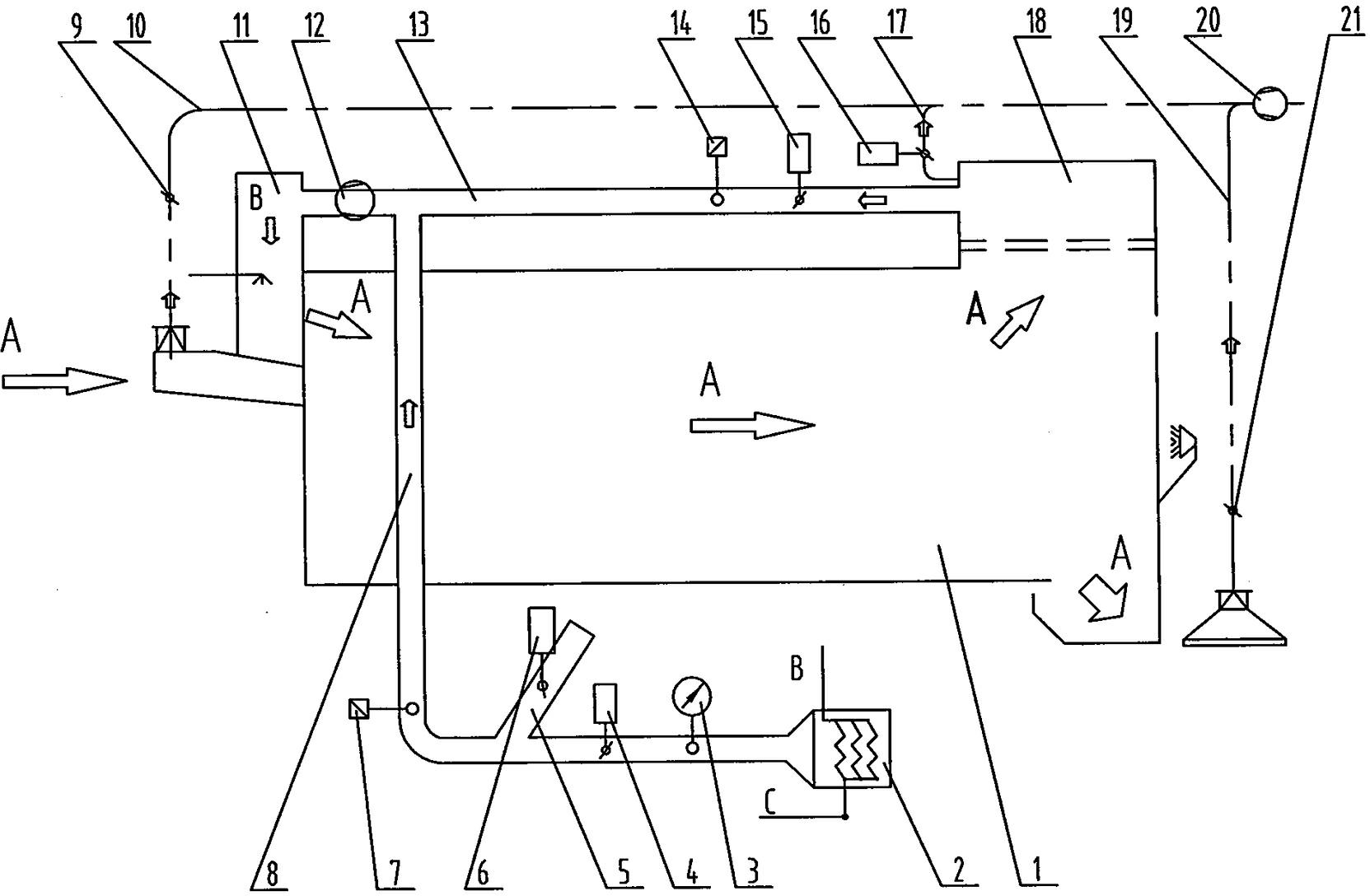

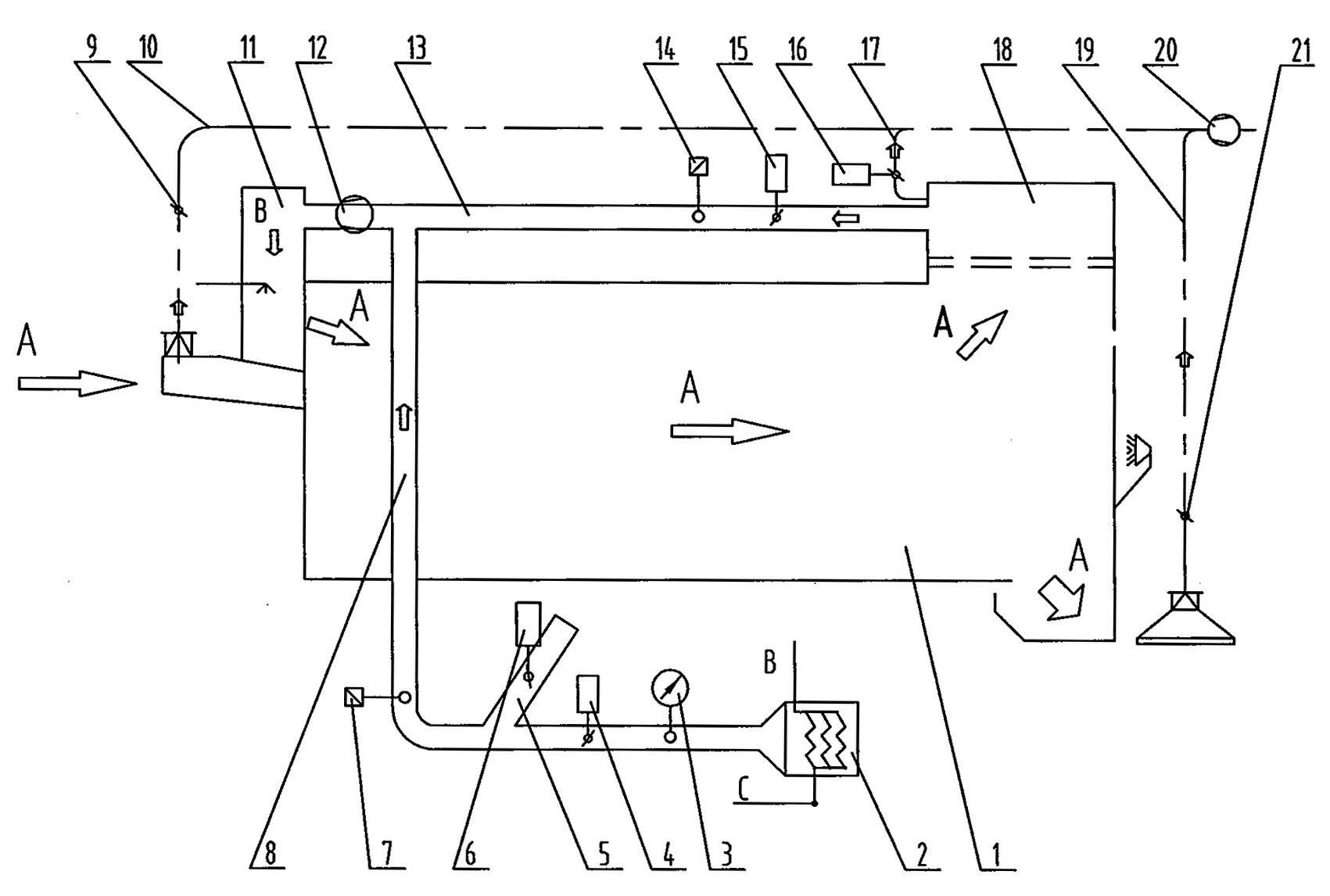

[0019] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

[0020] Such as figure 1 Shown is a hot air circulation device for a tobacco feeding machine, which is mainly composed of a hot air circulation channel and a radiator (2); the hot air circulation channel consists of a drum (1), a drum front chamber (11), The drum rear chamber (18) is formed with a pipeline (13) communicating with the front and rear chambers of the drum; the hot air circulation duct is provided with an air supply pipe (8) communicated with the radiator (2), and the air supply pipe is provided with There is an air supply port (5) with an electric angle actuator, an axial flow fan (12) is arranged on the hot air circulation duct, and is located between the drum front chamber (11) and the air supply duct (8), the hot air circulation duct A temperature sensor (14) is also arranged on it; the radiator (2) is also connected with an electric angle actuator (4).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com