Ultrasonic condensing and separating device with multiple air inlet nozzles

The technology of an intake nozzle and a separation device is applied in the field of multiple intake nozzle type supersonic condensation and separation devices, and can solve the problems of weak swirling capability of the cyclone device, unfavorable droplet growth, and reduced separation efficiency of the supersonic separator, etc. The effect of improving separation efficiency and reducing the effect of droplet re-evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

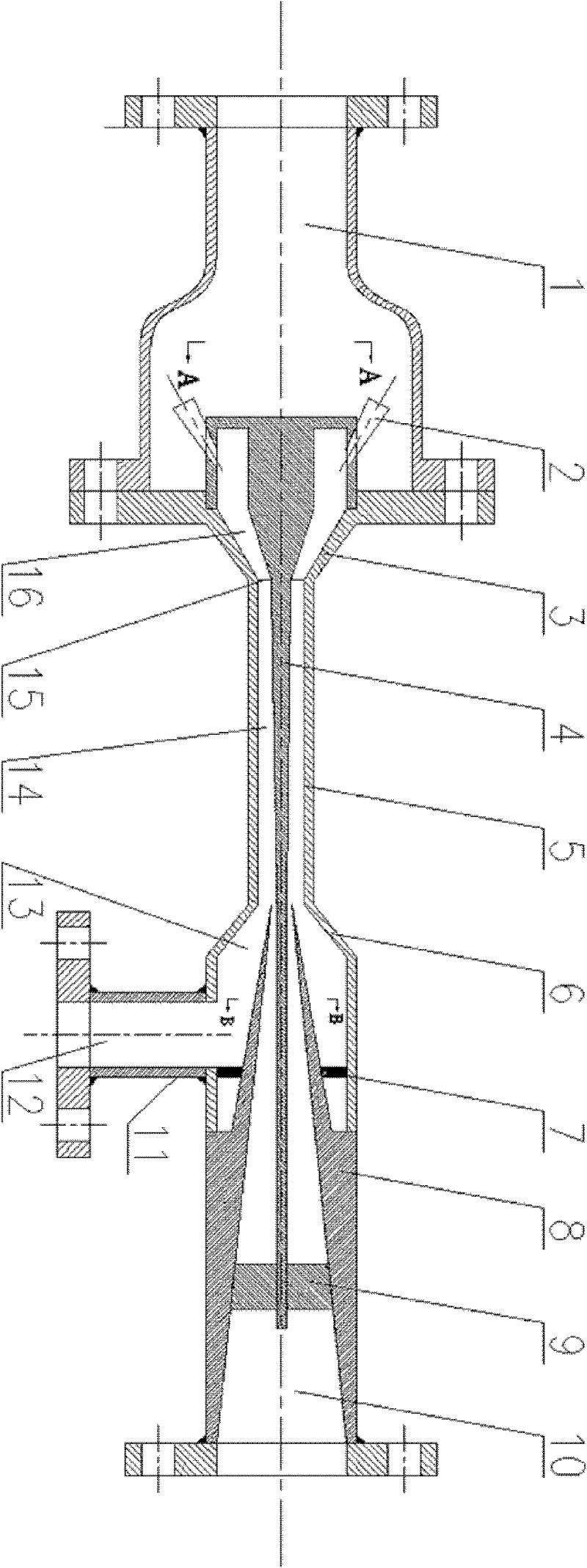

[0015] The structural features and working principles of the present invention will be further described below in conjunction with the accompanying drawings.

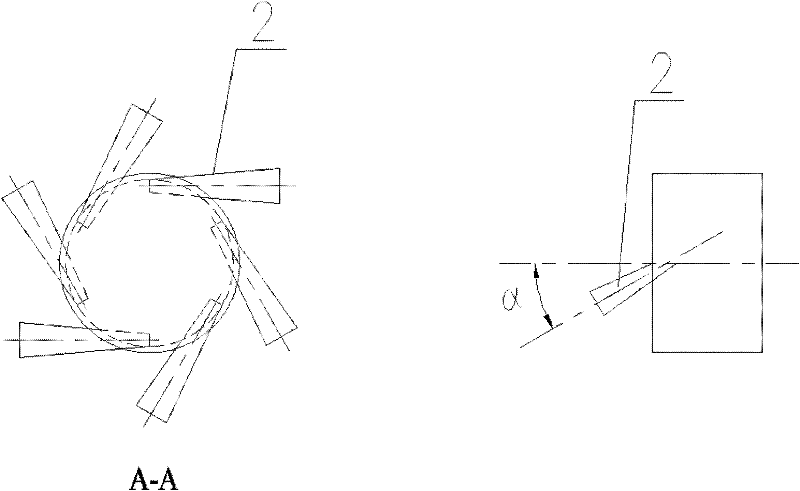

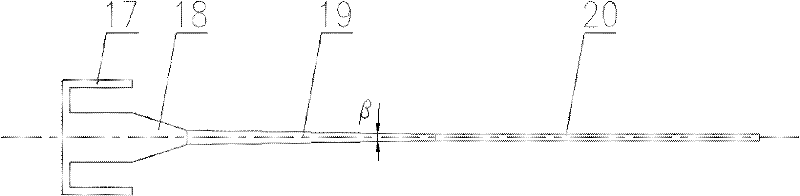

[0016] see figure 1 , 3, the present invention includes air intake chamber 1, air intake nozzle 2, contraction section 3, central body 4, outer straight pipe section 5, expansion section 6, positioning support rib 7, diffuser pipe 8, vortex arrester 9, dry gas Outlet 10, effusion cavity 13, drain tube 11 and liquid outlet 12; central body 4 includes straight tube 17, constriction cone section 18, tapering cone section 19 and cylindrical section 20, constriction section 3 and constriction section from left to right The conical section 18 forms an annular subsonic constriction channel 16 with a gradually decreasing area, the outer straight pipe section 5 and the tapering cone section 19 form an annular supersonic swirl separation channel 14 with a gradually increasing area, and the annular subsonic constriction channel 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com