Over-glaze ceramic decal paper and production method thereof

A technology of decal paper and ceramics, which is applied in the fields of technology and decorative art for producing decorative surface effects, and can solve the problems of high cost of film making, environmental and human injury, and visual nerve damage in the workshop environment, and achieves low cost and high-quality patterns. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

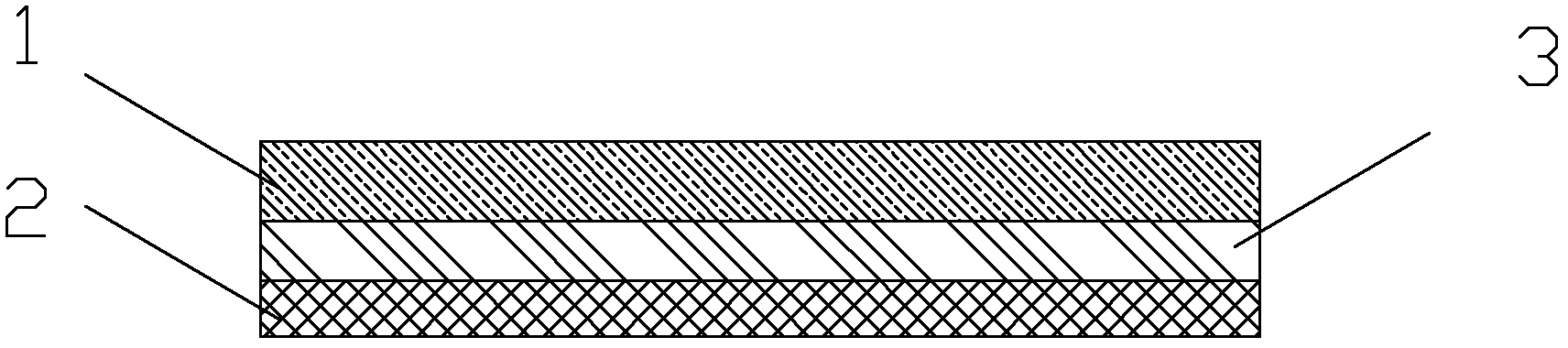

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

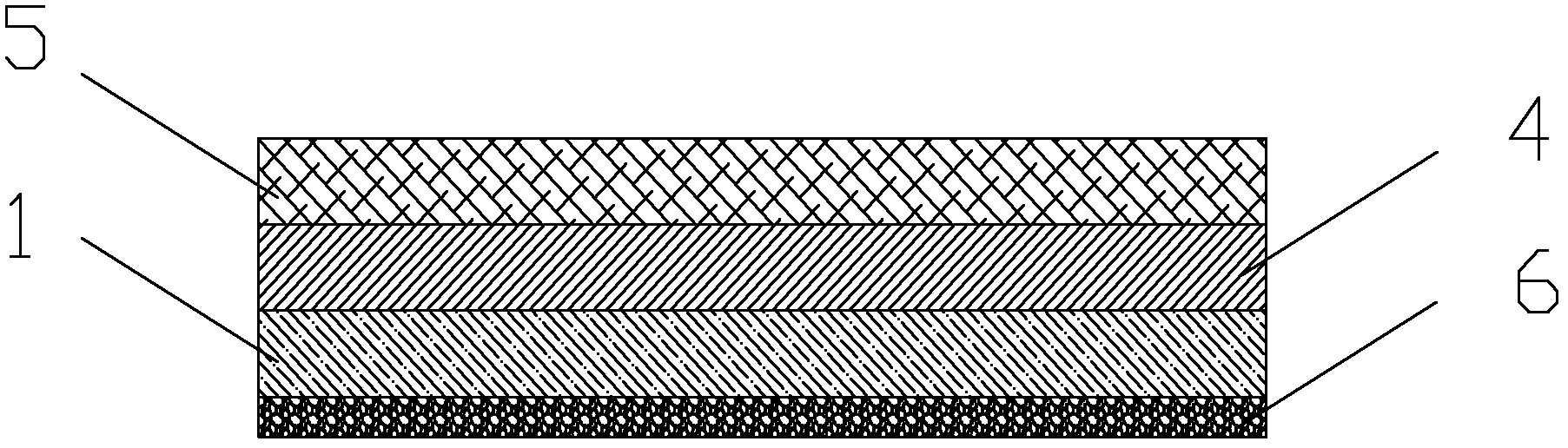

[0019] see figure 2 , glazed ceramic decal paper, a layer of water-soluble film 6 is arranged on one side of the pattern 1, and a layer of mulberry paper 5 is pasted on the other side of the pattern 1 through the glue layer 4.

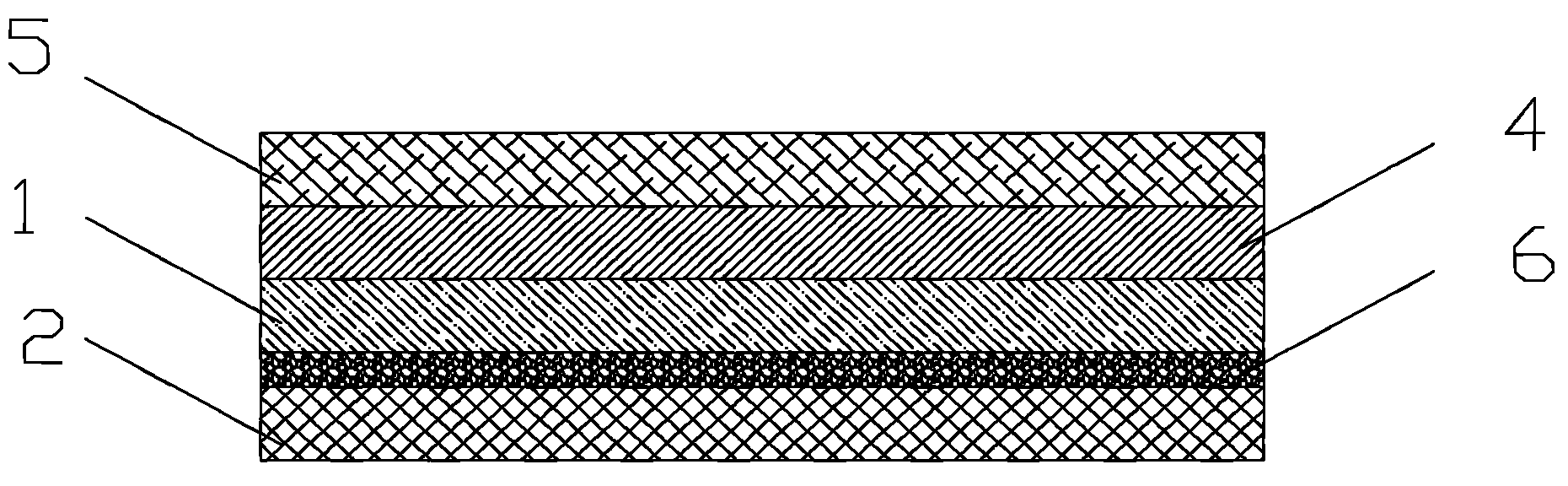

[0020] see image 3 , the production method of the overglaze ceramic decal paper provided by the invention, the steps are as follows:

[0021] (1), uniformly coat one layer of water-soluble glue on the hard bottom film 2, the water-soluble glue is made of polyacrylamide, polyvinyl alcohol or methyl cellulose with a mass concentration of 8% to 15% and good fluidity The glue solution, the water-soluble glue is dried to form a water-soluble film 6 with a thickness of 0.004-0.008mm;

[0022] (2), on this water-soluble film 6, adopt water-based binder color printing pigment, form pattern 1;

[0023] (3), after the patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap