New tigecycline crystal form and preparation method thereof

A technology of tigecycline and crystal form, applied in the field of new crystal form of tigecycline and its preparation, can solve the problems of inconvenient transportation or storage, limited medical use, unstable tigecycline powder, etc. Transportation and long-term storage, the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Preparation of tigecycline crystal form

[0056] Cool 300ml of ethanol with ice water to 15°C-20°C, add 10g of tigecycline amorphous under stirring, and stir to dissolve. Concentrate with a rotary evaporator under vacuum, and control the temperature of the water bath below 25°C. When concentrated to 100-110ml, stop concentrating. Put the concentrated solution in an ice-water bath, add 100-110ml of ethyl acetate while stirring, and when the ice-water bath is stirred to about 5°C, put it in a freezer (-20°C-0) to crystallize for 10-15 hours. After filtration, the crystal was vacuum pumped for 20-24 hours at 25°C-30°C to obtain 8.20 g of the new crystal form described in this patent (purity: 99.7%, residual solvent: ethanol 7.24%, ethyl acetate 2.9%).

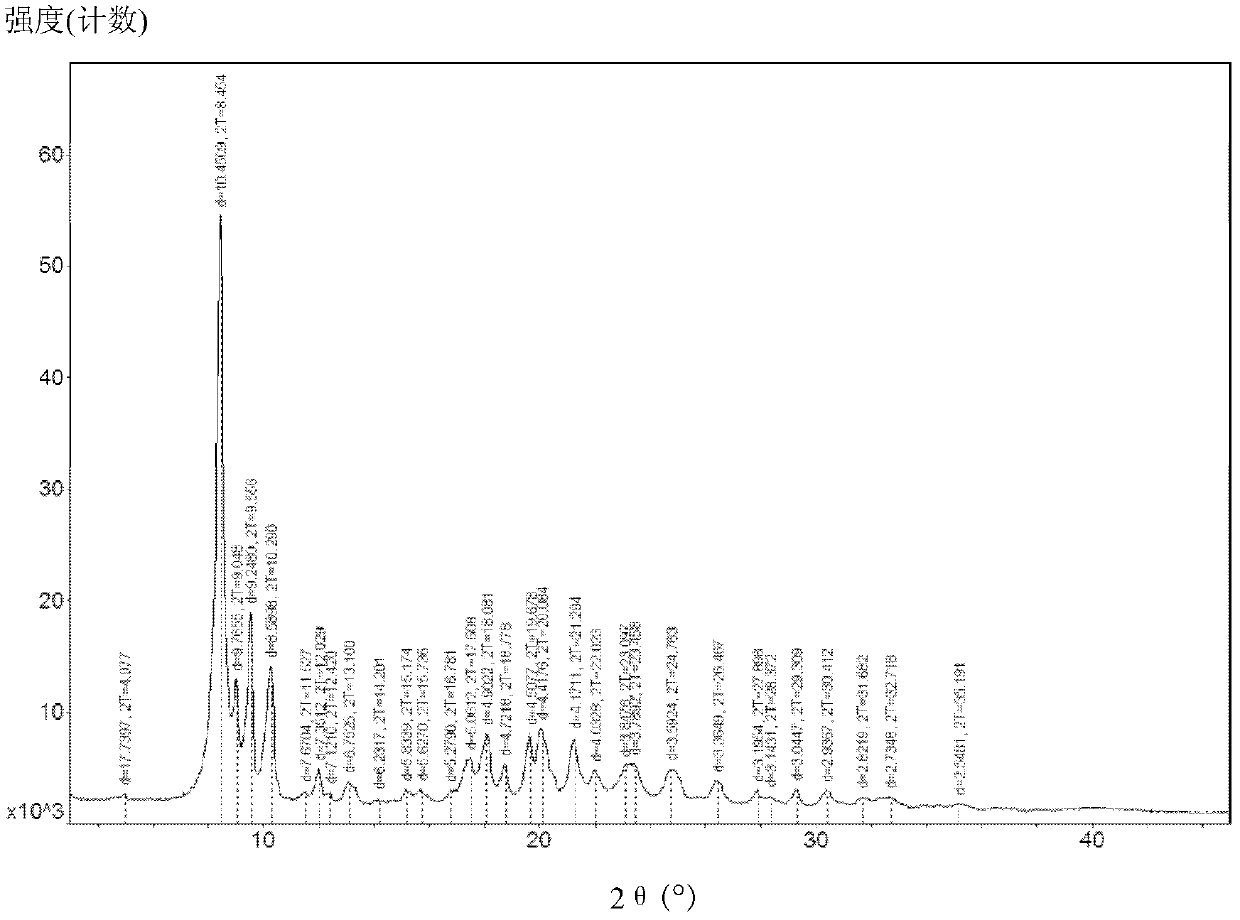

[0057] This crystal is used as a sample, and powder X-ray diffraction (hereinafter referred to as XRD) is measured to obtain figure 1 The X-ray diffraction pattern shown.

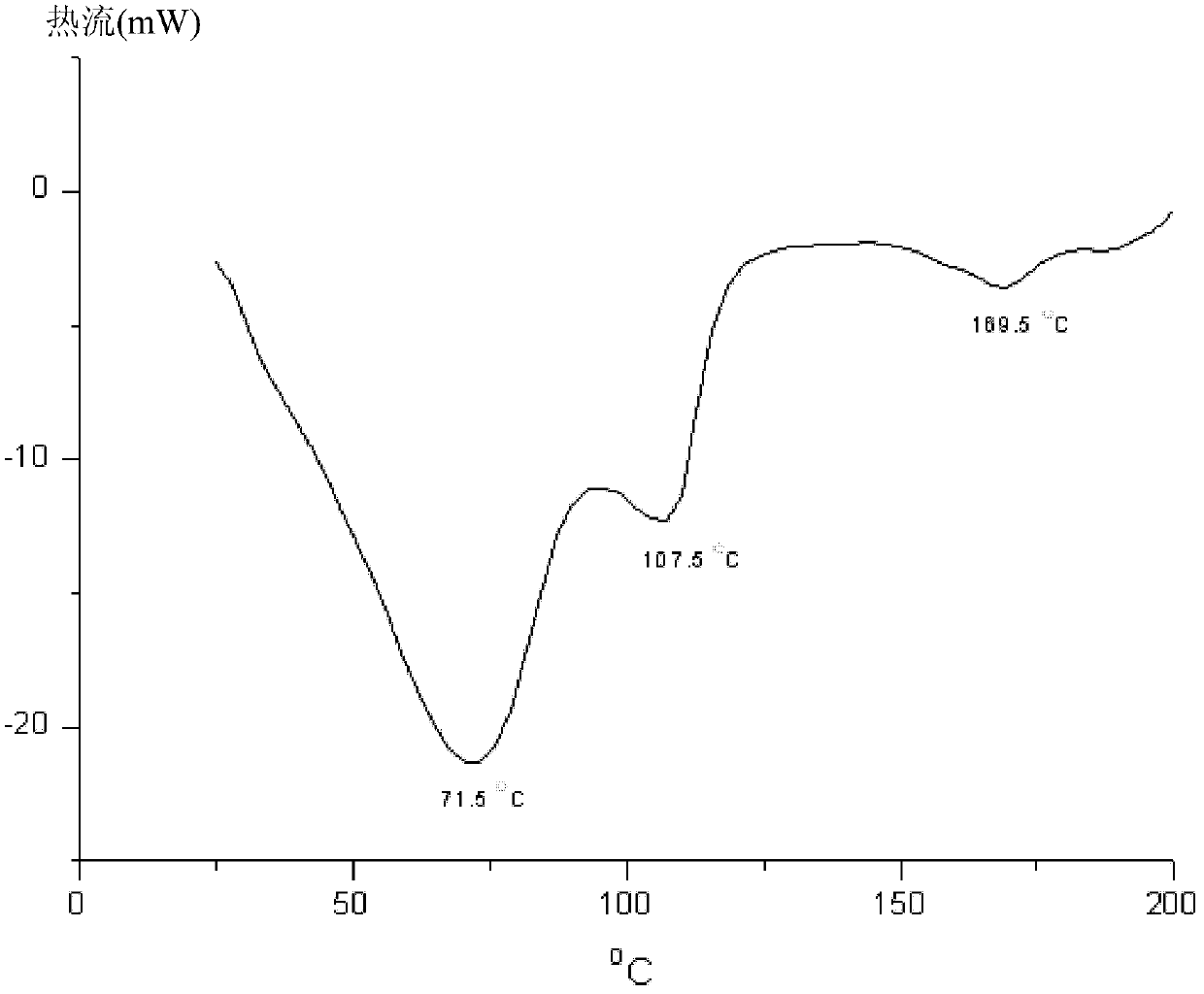

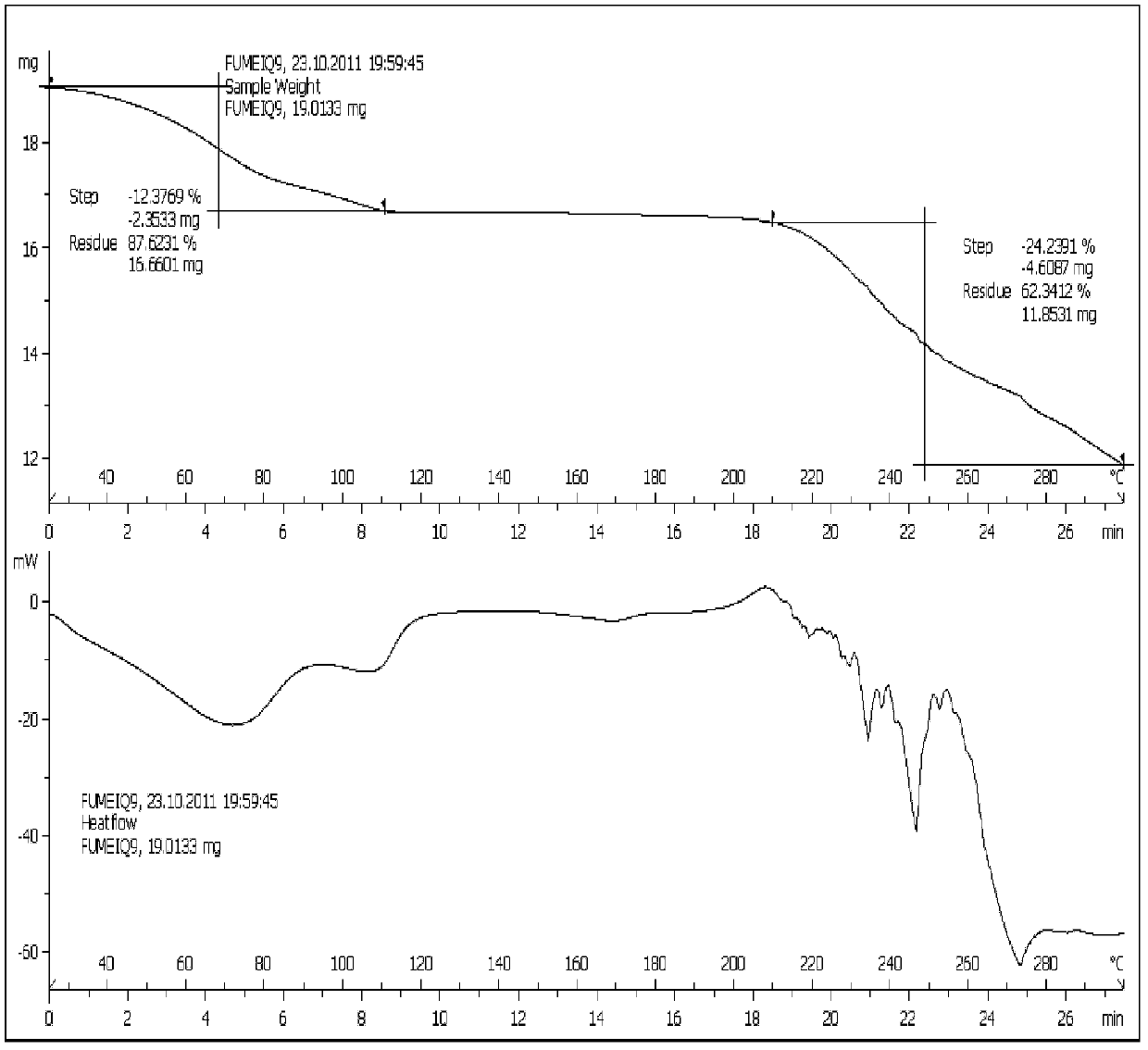

[0058] This crystallization is u...

Embodiment 2

[0060] Embodiment 2: Preparation of tigecycline crystal form

[0061] Cool 400ml of methanol with ice water to 15°C-20°C, add 10g of tigecycline amorphous under stirring, and stir to dissolve. Concentrate with a rotary evaporator under vacuum, and control the temperature of the water bath below 25°C. When concentrated to 100-110ml, stop concentrating. Put the concentrated solution in an ice-water bath, add 100-110ml of ethyl acetate while stirring, and when the ice-water bath is stirred to about 5°C, put it in a freezer (-20°C-0) to crystallize for 10-15 hours. Filtrate, vacuumize the crystal for 20-24 hours at 25°C to 30°C to obtain the new crystal form described in this patent, and obtain 9.1g of tigecycline crystal form (purity: 99.6%, residual solvent: methanol 0.24% , ethyl acetate 3.7%). The X-ray diffraction figure of described crystal form tigecycline is as attached figure 1 shown.

Embodiment 3

[0062] Embodiment 3: Preparation of tigecycline crystal form

[0063] Cool 300ml of isopropanol with ice water to 15°C to 20°C, add 10g of tigecycline amorphous under stirring, and stir to dissolve. Concentrate with a rotary evaporator under vacuum, and control the temperature of the water bath below 25°C. When concentrated to 100-110ml, stop concentrating. Put the concentrated solution in an ice-water bath, add 100-110ml of ethyl acetate while stirring, and when the ice-water bath is stirred to about 5°C, put it in a freezer (-20°C-0) to crystallize for 10-15 hours. After filtration, the crystals are vacuumed for 20 to 24 hours in an environment of 25°C to 30°C to obtain the new crystal form described in this patent. 8.7 g of tigecycline were obtained (purity: 99.5%, residual solvent: isopropanol 7.32%, ethyl acetate 1.7%). The X-ray diffraction figure of described crystal form tigecycline is as attached figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com