Short-slab-span cast-in-situ beam ribbed floor early-dismantling template formwork system

A technology for early dismantling of formwork and floor formwork, applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of high cost and achieve low cost, The effect of saving wood and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

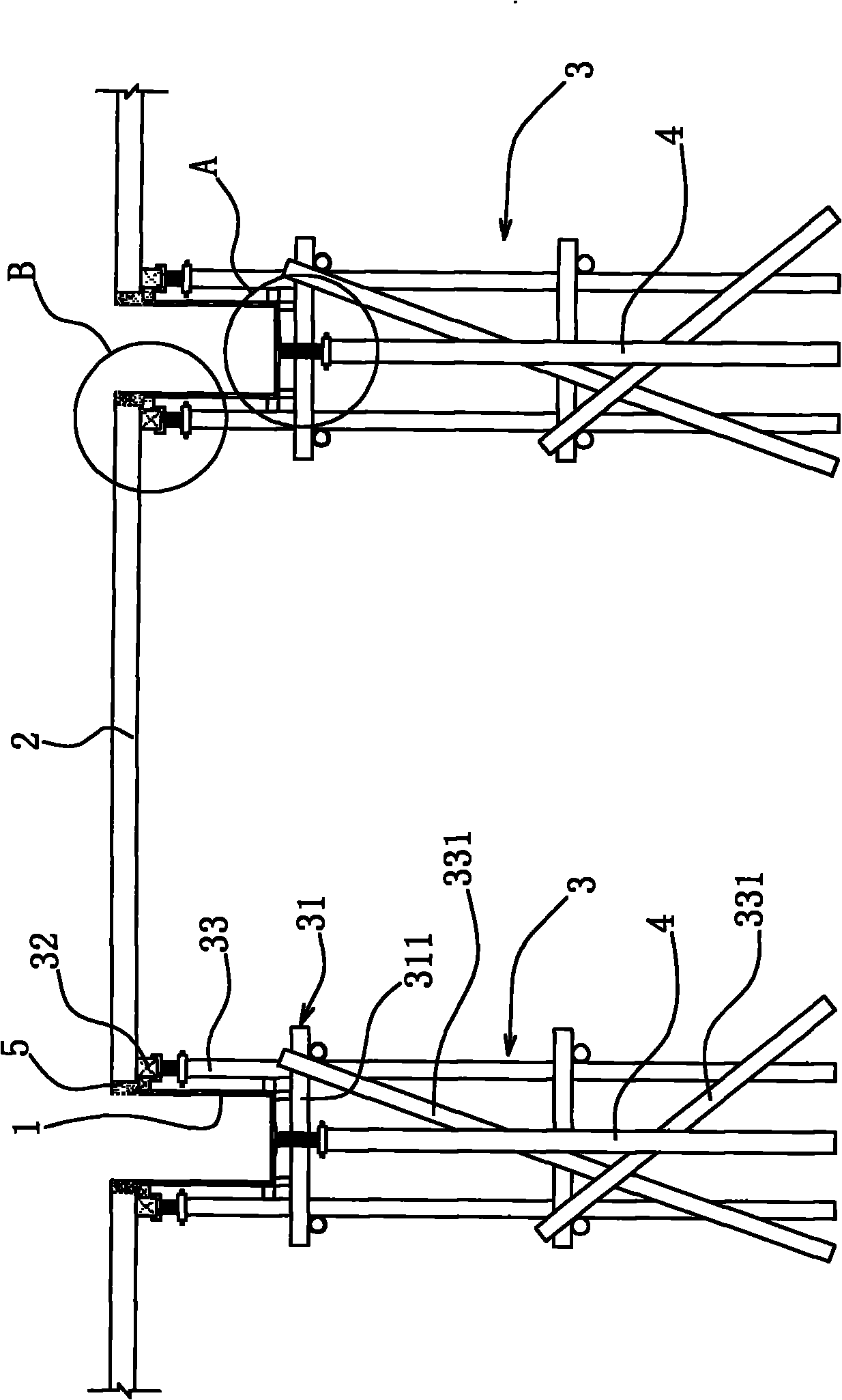

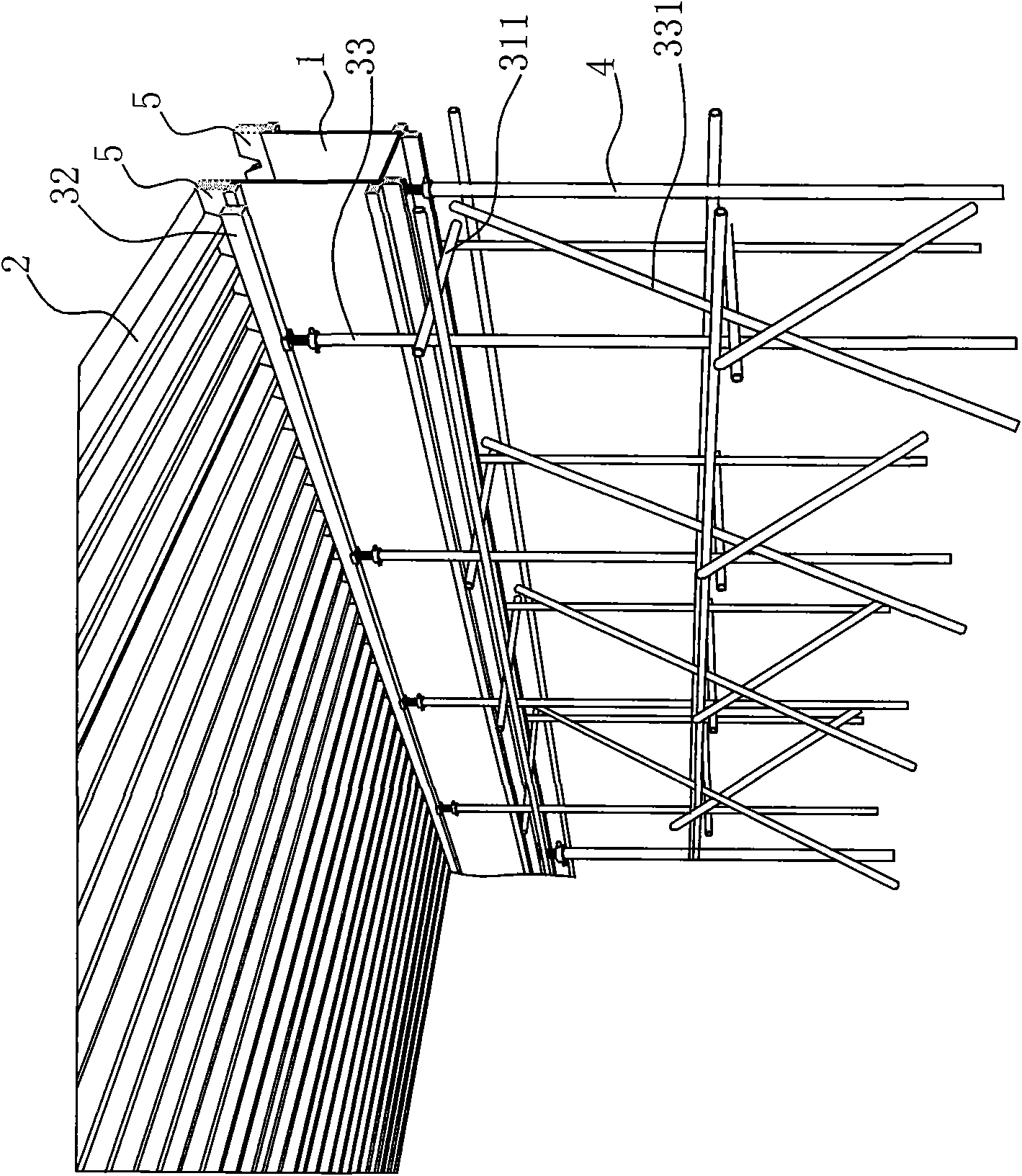

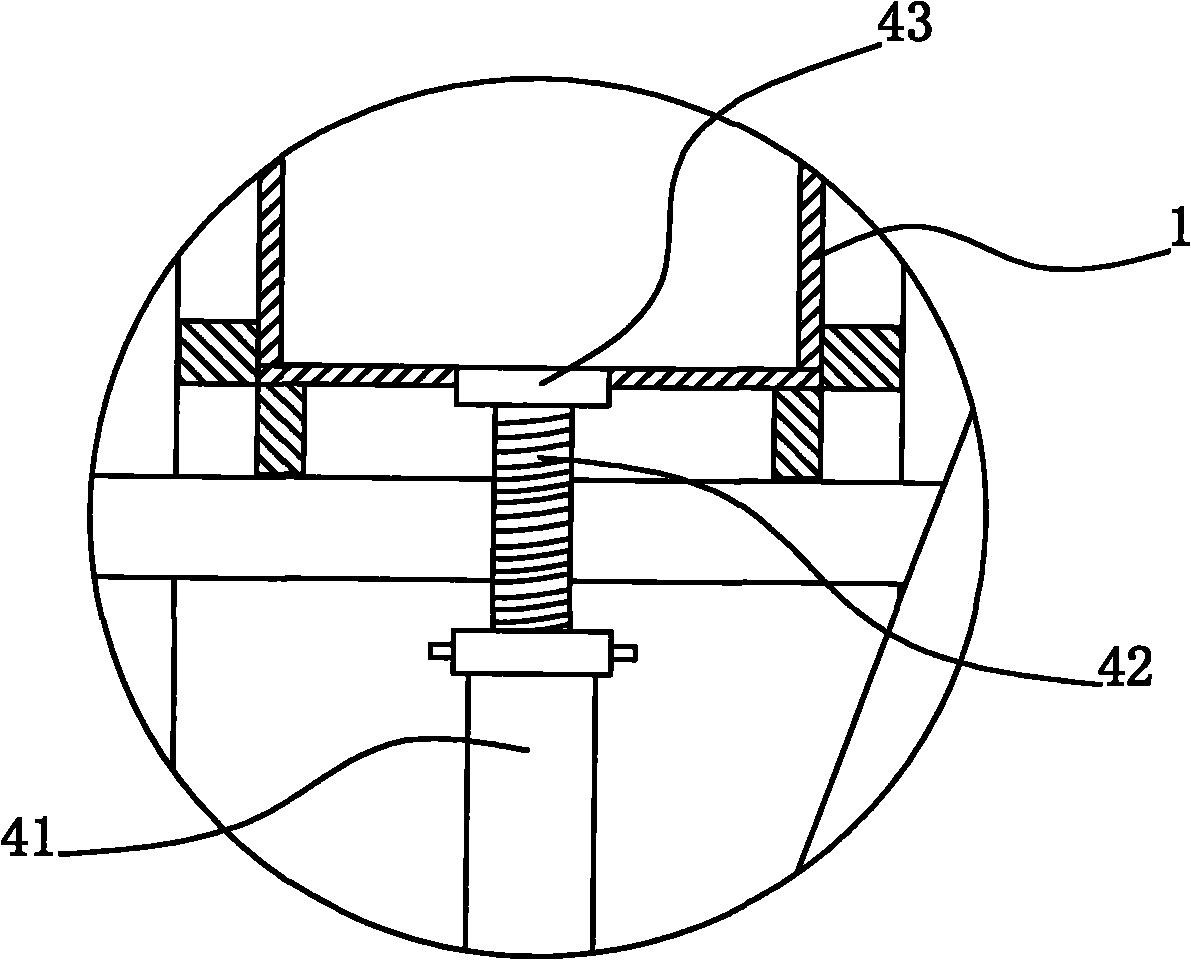

[0026] see figure 1 and figure 2 , in the embodiment of the small-span cast-in-place beam densely ribbed slab early demolition formwork support system provided by the present invention, it includes a beam formwork 1, a densely ribbed slab formwork 2 and a bracket supporting the beam formwork 1 and the densely ribbed slab formwork 2 3. It also includes an adjustable post 4 under the beam for supporting the lower part of the beam body. The adjustable post 4 under the beam is removed later than the support 3, the beam formwork 1 and the ribbed floor formwork 2. The support 3 includes The under-beam formwork support 31 supported at the bottom of the beam formwork 1, the support beam 32 supported at the end of the densely ribbed floor formwork 2 and the beam pillar 33 supporting the support beam 32, the densely ribbed floor formwork 2 is Profiled steel formwork, the profiled steel formwork 2 straddles the supporting beams 32 on the left and right sides, the end of the densely rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com