Self-balanced underground full-bore check valve

A single-flow valve and full-bore technology, which is applied to wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., can solve the problems of prolonging construction operation time, reducing operation efficiency, increasing operation cost, etc. problems, to achieve the effect of improving production safety, improving work efficiency and shortening working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

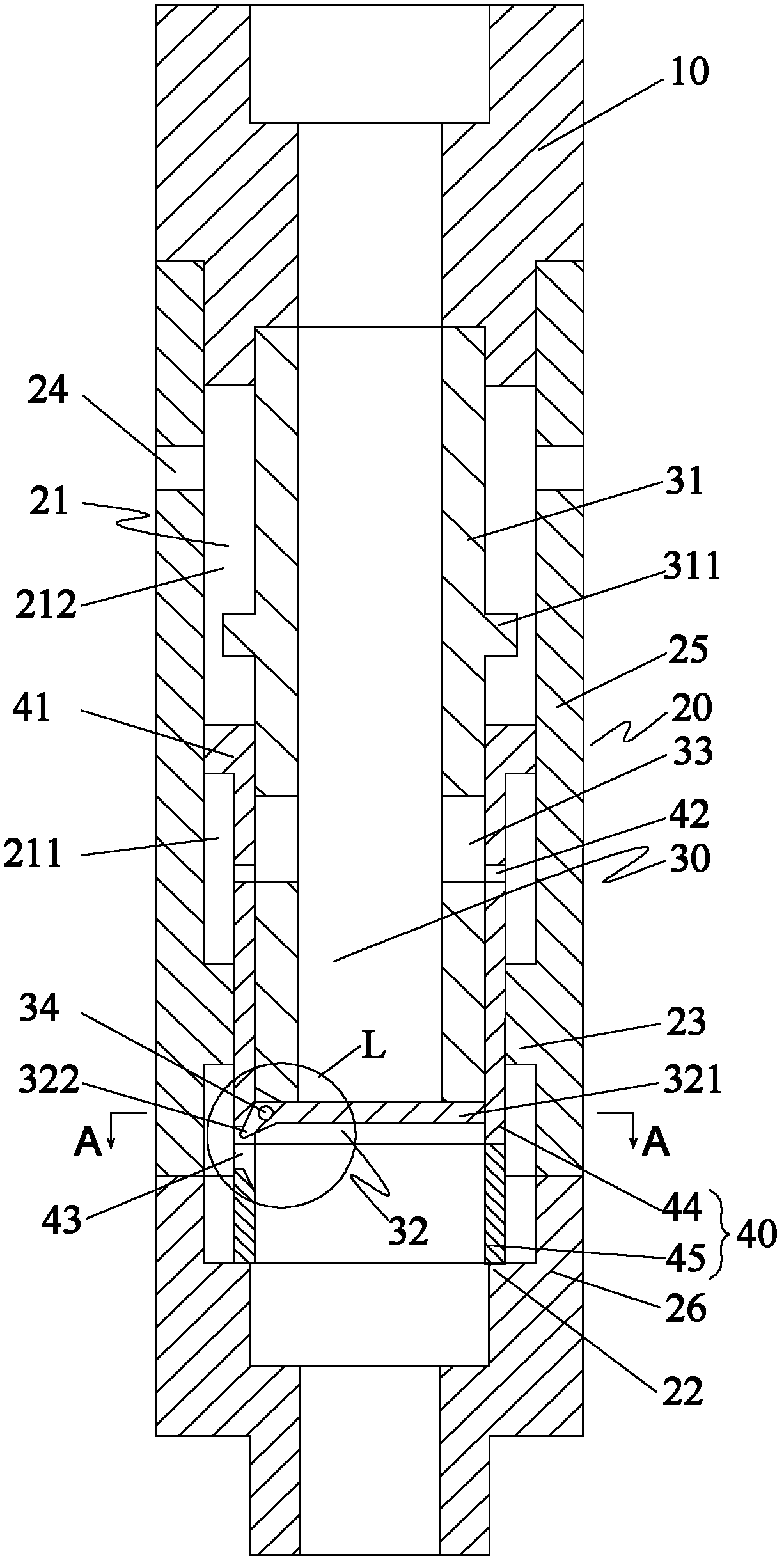

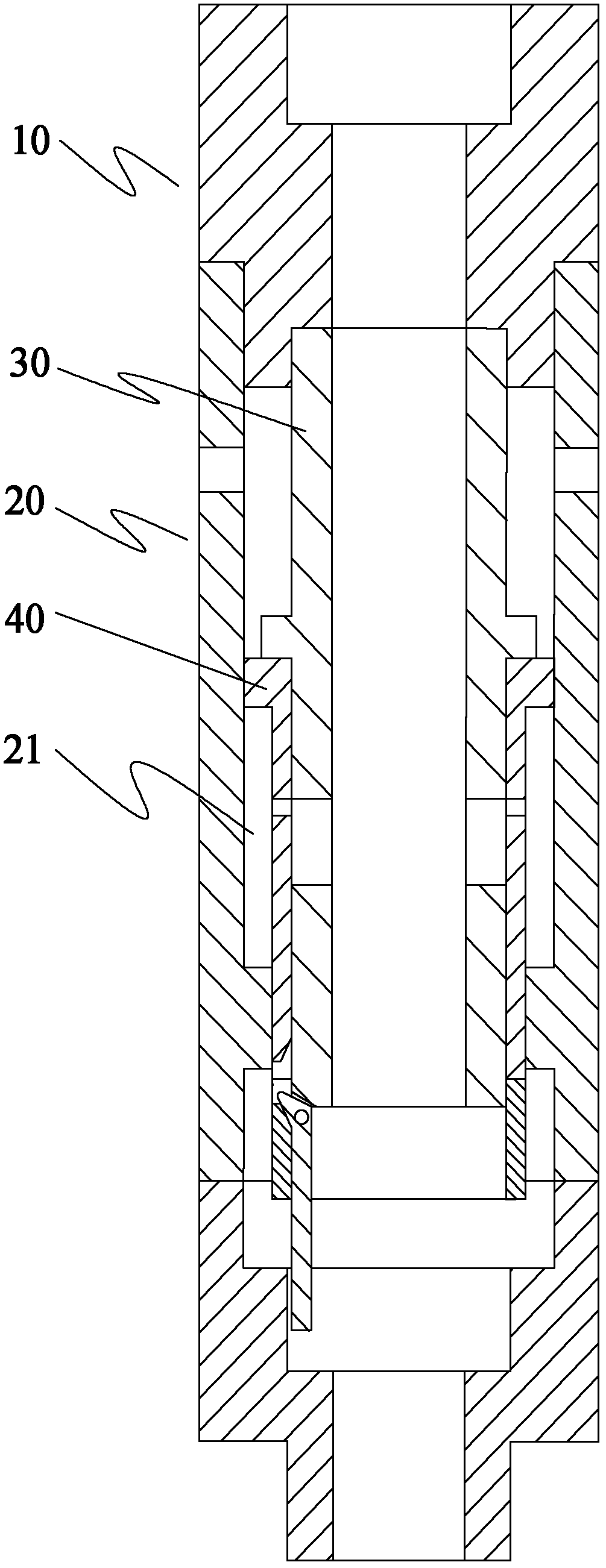

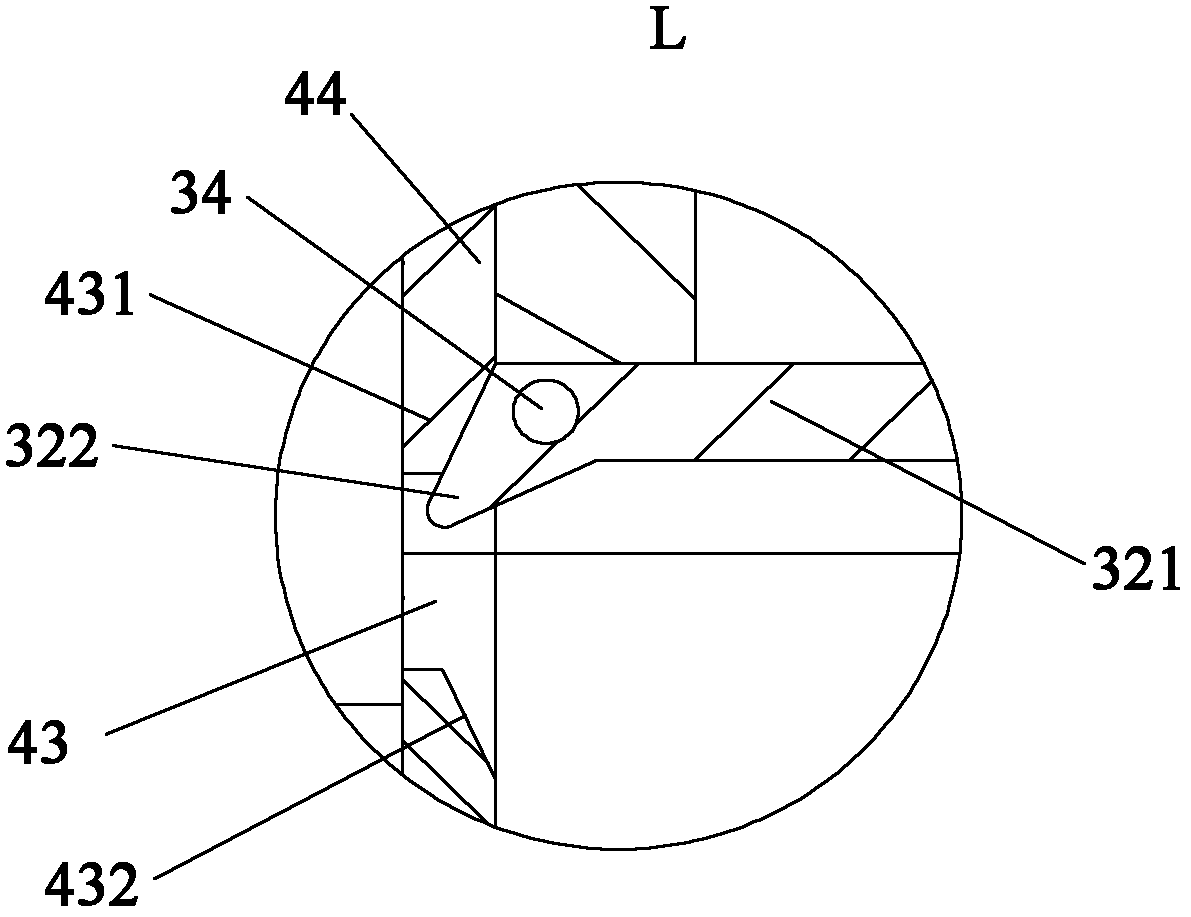

[0027] like figure 1 and figure 2 As shown, according to the embodiment of the present invention, the self-balancing downhole full-bore check valve includes a first joint 10 and a second joint 20, and the first ends of the first joint 10 and the second joint 20 are fixedly connected, and the fixed connection The method is, for example, welding. An accommodating chamber 21 is formed in the second joint 20 , and an on-off valve 30 is disposed in the accommodating chamber 21 . A sliding sleeve 40 is disposed in the annular cavity formed by the on-off valve 30 and the second joint 20 . The sliding sleeve 40 is sleeved on the on-off valve 30 and can slide along the axial direction of the on-off valve 30 .

[0028] The first joint 10 , the second join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com