Device and method for controlling misfire of spark ignition engine

A spark ignition, engine technology, applied in automatic control, automatic control, electrical automatic control and other directions, can solve the problems of easy misdiagnosis, short service life, high price of in-cylinder pressure sensor, etc., to achieve accurate and reliable misfire diagnosis, Hazard minimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below with reference to the embodiments shown in the accompanying drawings.

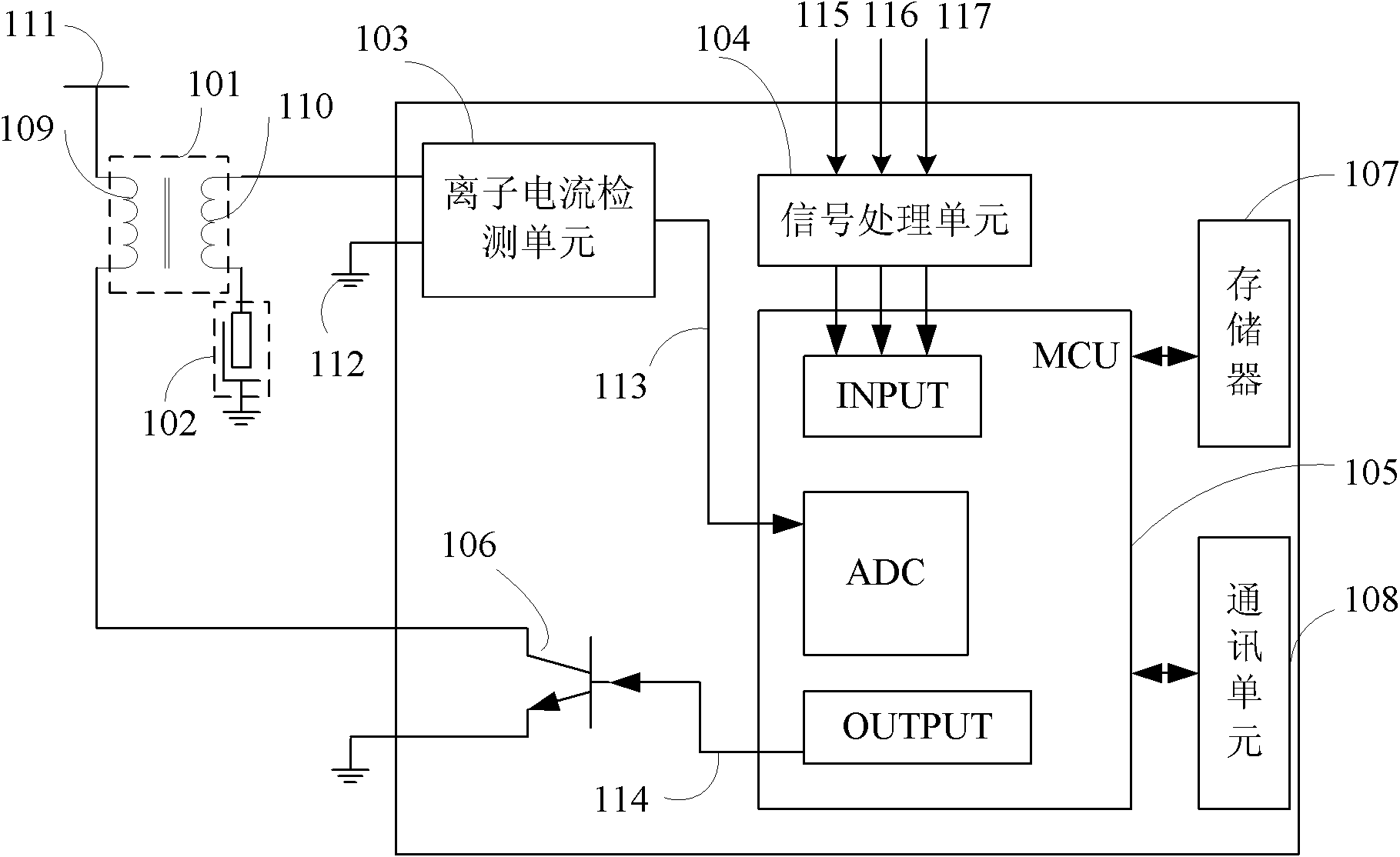

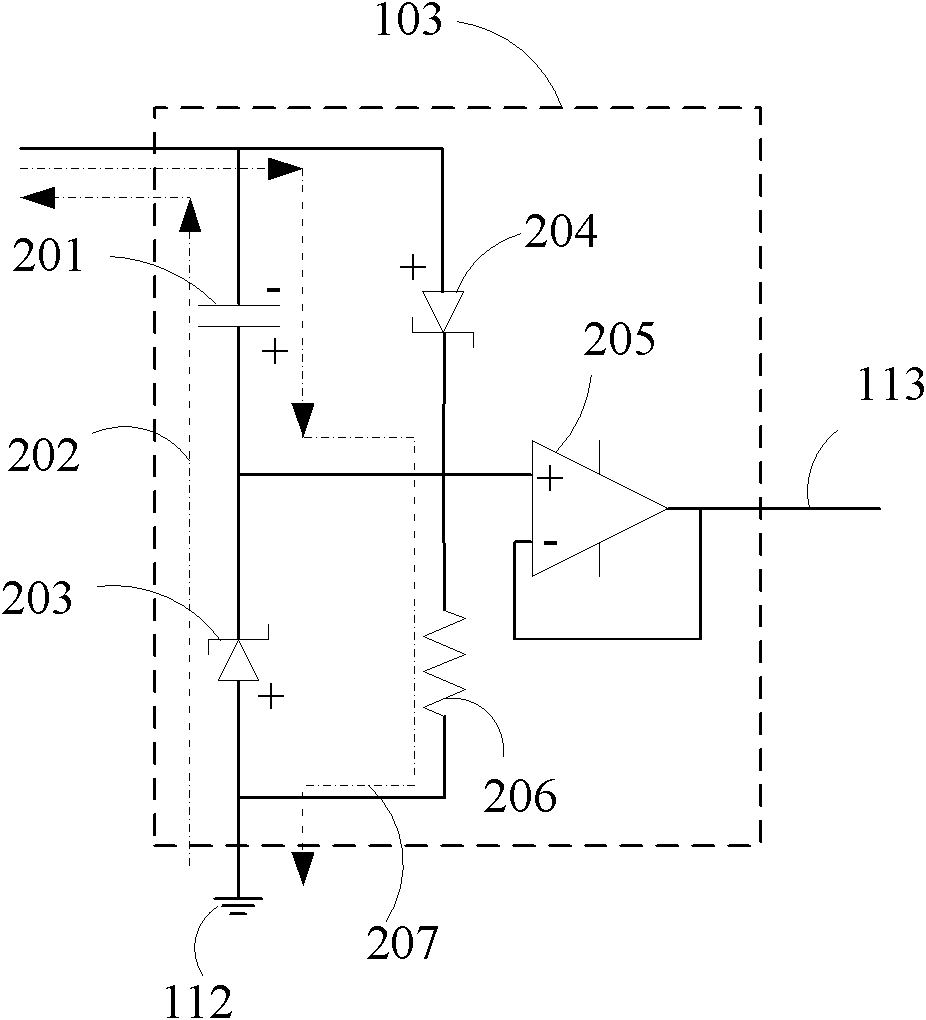

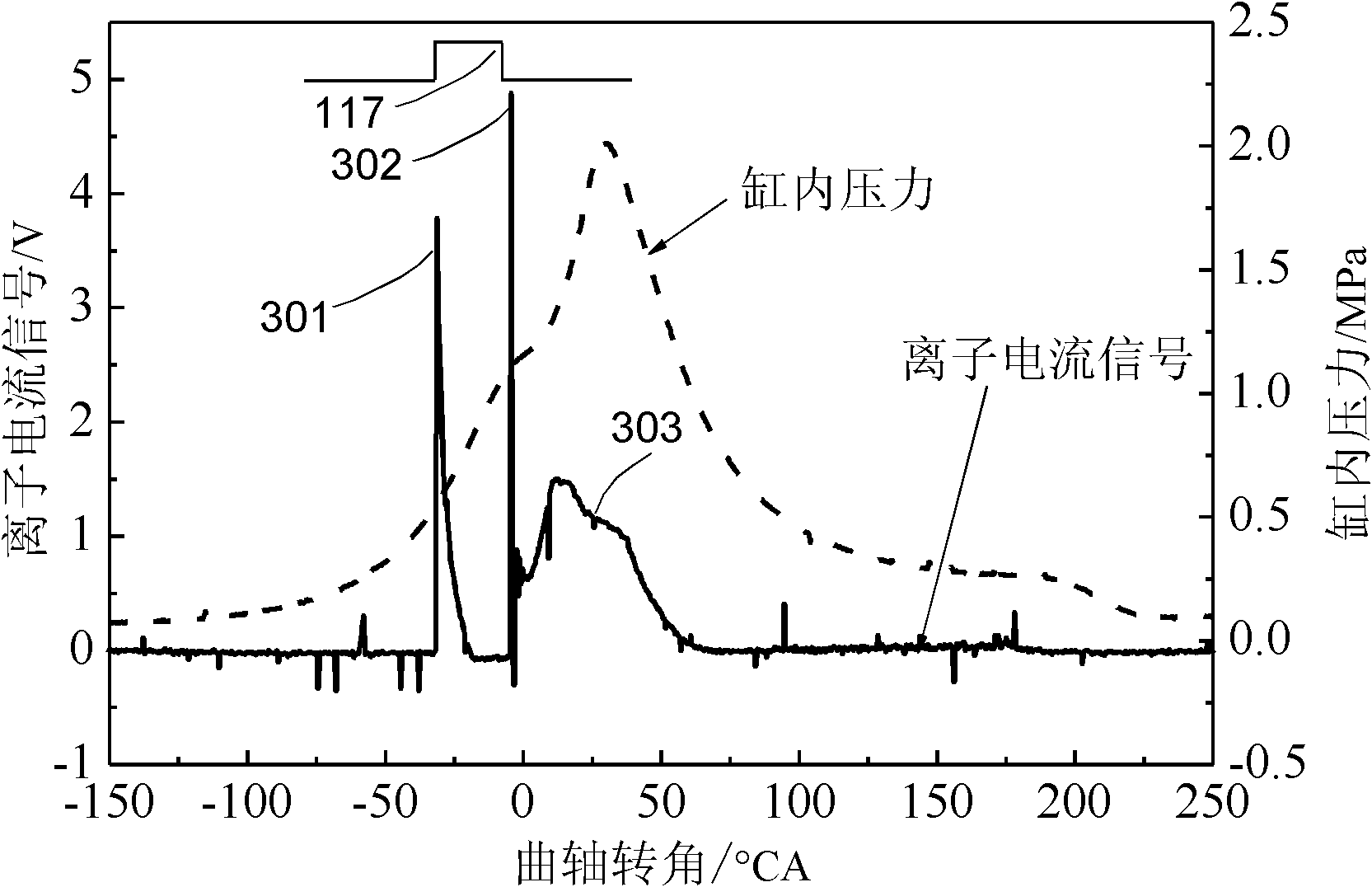

[0058] figure 1It is a schematic diagram of the device principle for spark ignition engine misfire control. The device comprises an ignition coil, a spark plug 102, an ion current detection unit 103, a signal processing unit 104, a micro control unit 105 and an ignition drive unit 106, and the ion current detection unit 103 is connected in series by the secondary coil 110 of the ignition coil, the spark plug In the circuit formed by 102 and ground 112, the ground can also be regarded as the engine block. The ion current signal 113 detected by the ion current detection unit 103 is input to the analog-to-digital conversion module ADC of the micro control unit 105 connected thereto. The engine working state signal enters the input module INPUT of the micro control unit 105 after being filtered, limited, shaped and buffered by the signal processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com