Micro electromagnetic vibration energy harvester based on patterned permanent magnet full integration

An electromagnetic vibration and energy harvester technology, applied in the field of micro-electromechanical, can solve the problems of numerous and complex manufacturing process steps, difficulty in mass production, difficulty in parameter control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

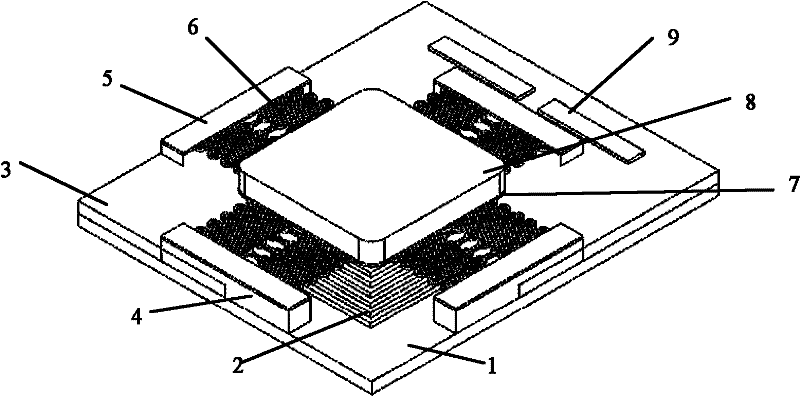

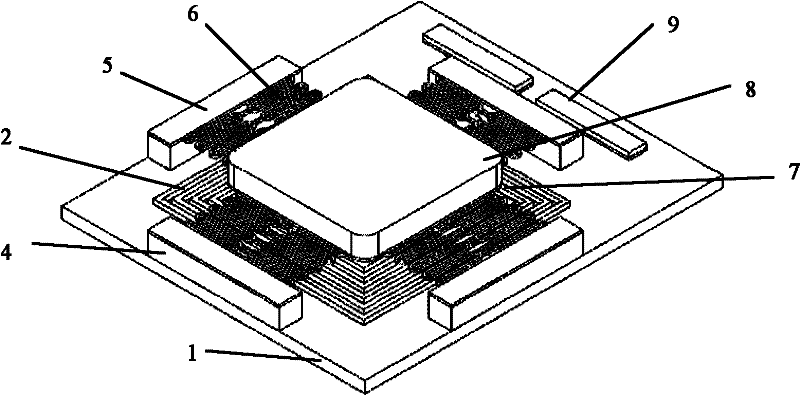

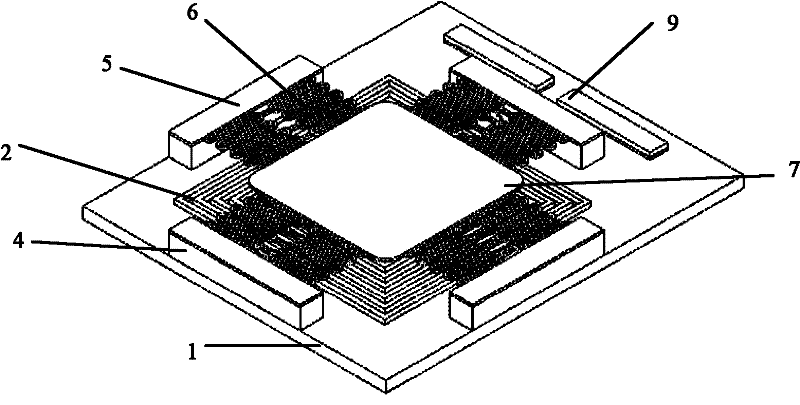

[0031] The embodiment is based on a fully integrated miniature electromagnetic vibration energy harvester with patterned permanent magnets

[0032] Such as figure 1 As shown, this embodiment includes: an insulating substrate 1, a planar spiral induction coil 2, an insulating material coating layer 3, a supporting structure 4, a connecting piece 5, a serpentine spring 6, a gasket 7, a patterned permanent magnet 8, and a lead wire Electrode 9. Four sets of supporting structures 4 are fixed on the insulating substrate 1, the connecting piece 5 is fixed on the supporting structure 4, the serpentine spring 6 is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com