motor control unit

A motor control and circuit technology, used in AC motor control, current controller, electronic commutation motor control, etc., can solve problems such as increased noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

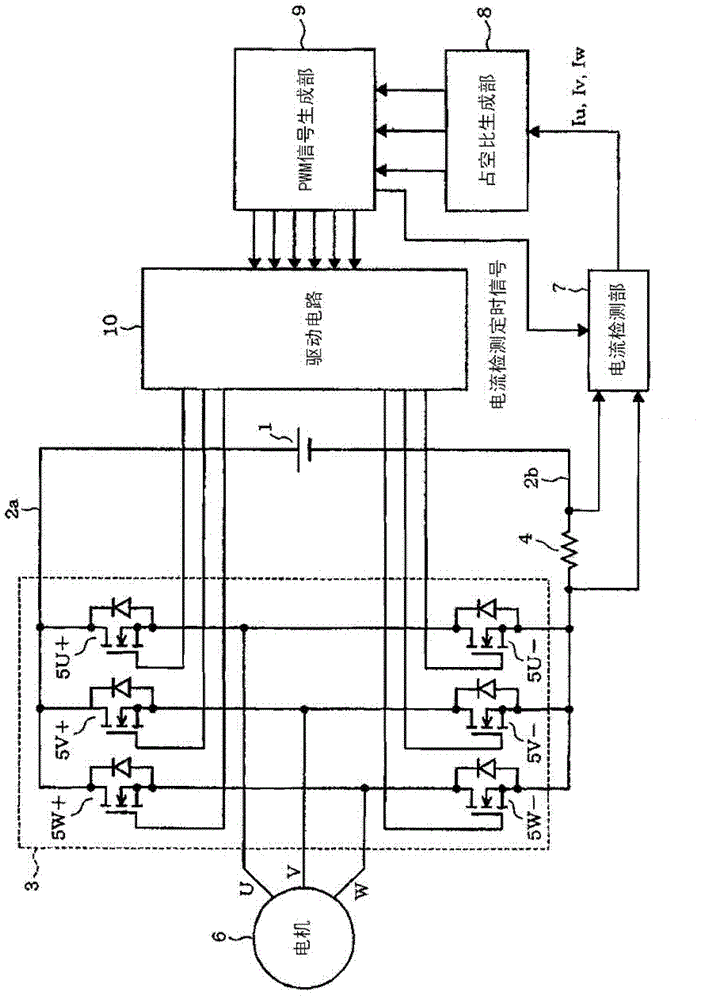

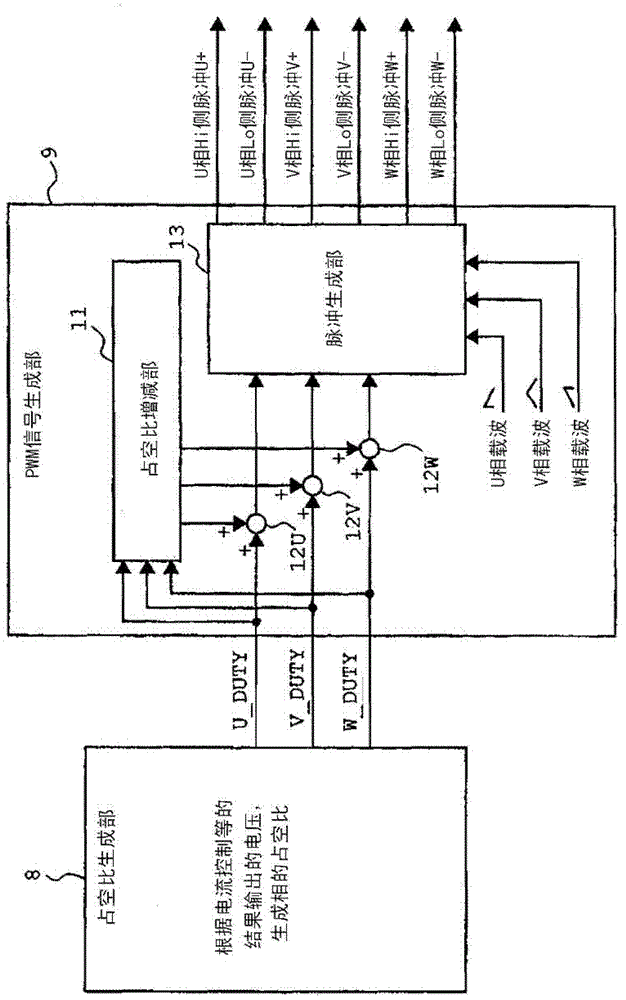

[0029] Refer below Figure 1 to Figure 11 The first embodiment will be described. figure 1 It is a functional block diagram showing the configuration of the motor control device. The DC power supply unit 1 is represented by a symbol of a DC power supply, but includes a rectification circuit and / or a smoothing capacitor when the DC power is generated from a commercial AC power supply. DC power supply unit 1 is connected to converter circuit (DC / AC converter) 3 via positive side bus 2 a and negative side bus 2 b , but shunt resistor 4 as a current detection element is inserted on the side of negative side bus 2 b . The converter circuit 3 is composed of, for example, N-channel type power MOSFETs 5 (U+, V+, W+, U-, V-, W-) connected to a three-phase bridge, and the output terminals of each phase are connected to a motor composed of, for example, a brushless DC motor. The coils of each phase of 6 are connected respectively.

[0030] The terminal voltage (signal corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com