Roller wheel for track belt-type traveling vehicle

A crawler type and vehicle technology, which is applied in the field of runners of crawler type vehicles, can solve the problems of easy deformation and uneven contact of the inner circumference of the roller sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

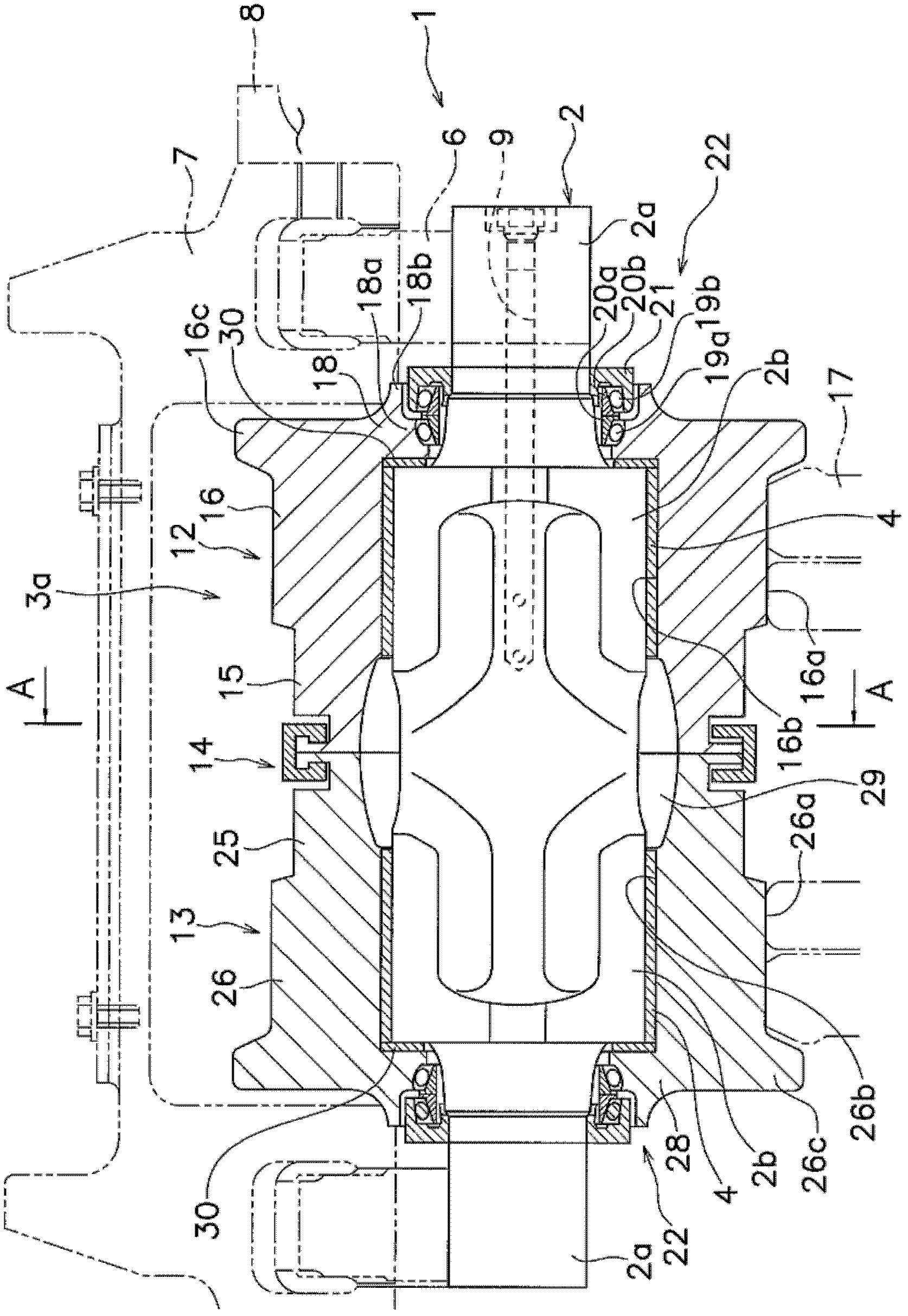

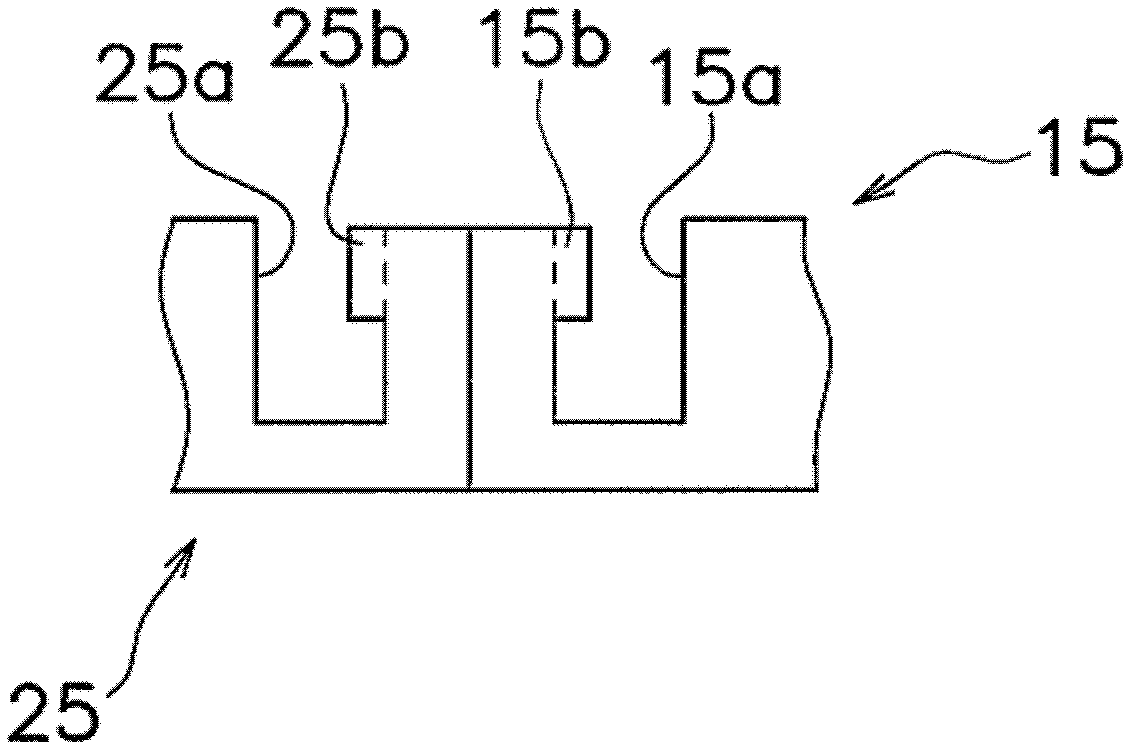

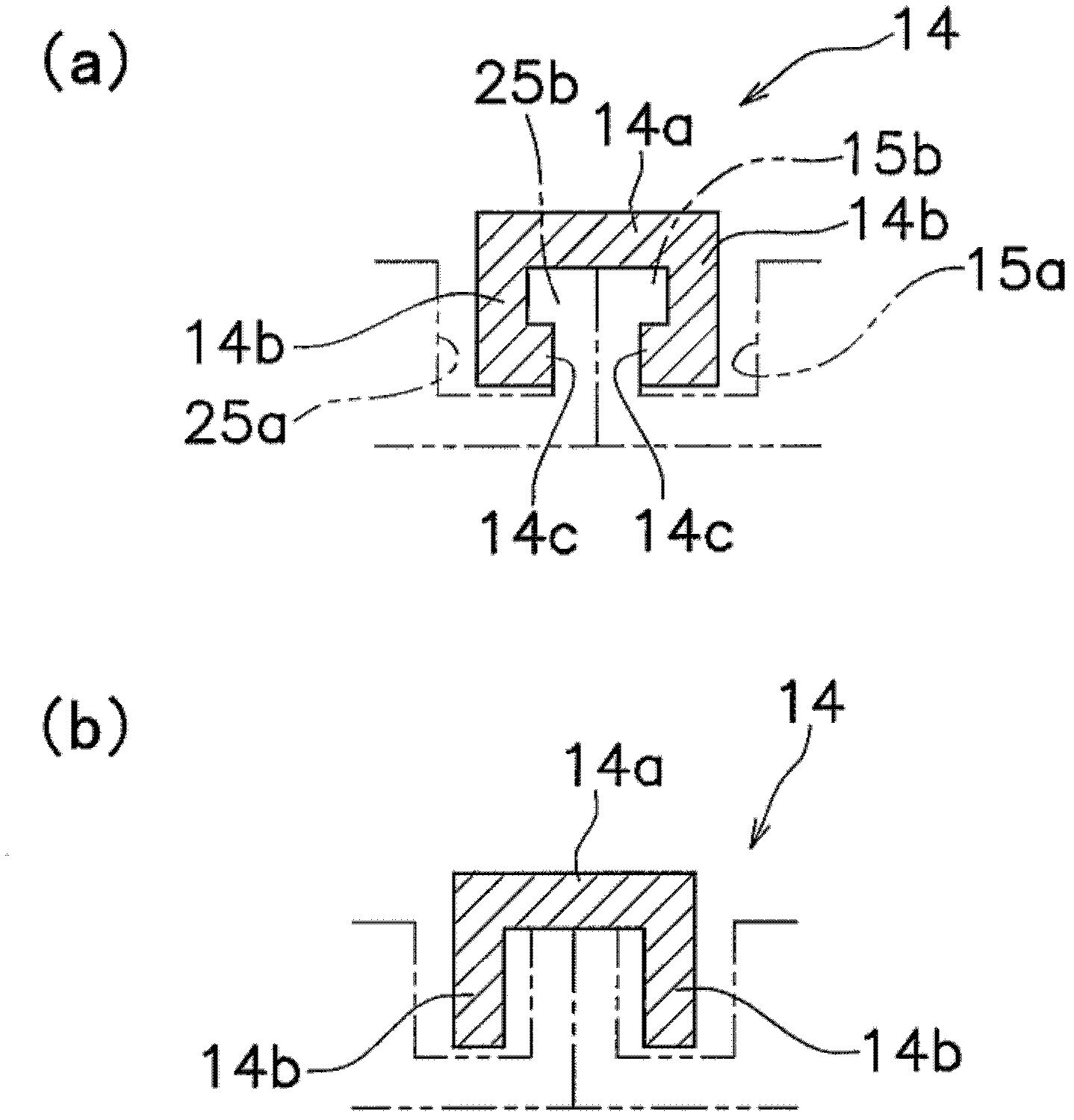

[0070] figure 1 It is a longitudinal sectional view of the running wheel of the crawler-type traveling vehicle according to the first embodiment of the present invention. The runner 1 is provided on the non-contact surface side of the crawler belt, and has a shaft 2, a roller assembly 3a, and two bushes 4 as bearings.

[0071] [axis]

[0072] The shaft 2 has a small-diameter support portion 2a at both ends, ie, an inner end and an outer end, and has two bearing mounting portions 2b having a larger diameter than the support portion 2a at a central portion where the roller assembly 3a is provided. Here, "inside" refers to the side close to the vehicle body frame 8, that is, figure 1 In the right side, "outside" refers to the side away from the vehicle body frame 8 that is figure 1 in the left side. The supporting parts 2a are respectively supported on the large steering members 7 (big boggies) via the small steering members (small boggies) 6 . Furthermore, the large stee...

no. 2 example

[0103] [structure]

[0104] Figure 9 A runner 40 showing a second embodiment of the present invention is shown. The runner 40 of the second embodiment differs from the first embodiment only in the inner roller sleeve, outer roller sleeve, and coupling ring constituting the roller assembly, and the other structures are the same as in the first embodiment. Only the parts different from the first embodiment will be described here.

[0105] The roller assembly 3b is the same as the first embodiment, and has an inner roller sleeve 42 arranged on the inner side close to the vehicle body frame, an outer roller sleeve 43 arranged on the outer side of the inner roller sleeve 42, and is used to combine the two rollers. The coupling ring 44 of the sleeve 42,43.

[0106] The inner sleeve 42 is formed in a cylindrical shape, and has an inner joining portion 45 and an inner tread portion 46 from the outer side toward the inner side.

[0107] As enlarged Figure 10 As shown, the inner ...

no. 3 example

[0122] Figure 14 A longitudinal sectional view showing a running wheel of a crawler-type traveling vehicle according to a third embodiment of the present invention. This runner 101 is provided on the non-contact surface side of the track, and has a shaft 102, a roller assembly 103a, and two bushes 104 as bearings.

[0123] [axis]

[0124] The shaft 102 has a small-diameter support portion 102a at both ends, ie, an inner end and an outer end, and has two bearing mounting portions 102b having a larger diameter than the support portion 102a at a portion where the roller assembly 103a is provided. The supporting parts 102a are respectively supported on the large steering members 107 via the small steering members 106 . Also, a large steering member 107 is fixed to a vehicle body frame 108 . Thus, axle 102 is supported on vehicle body frame 108 . Furthermore, the shaft 102 is formed with an oil supply hole 109 extending from one end on the inside toward the outside and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com