Double-acting synchronizer

A double-acting, synchronizer technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problem that the transmission is not an ideal solution, and achieve the effect of reducing the axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

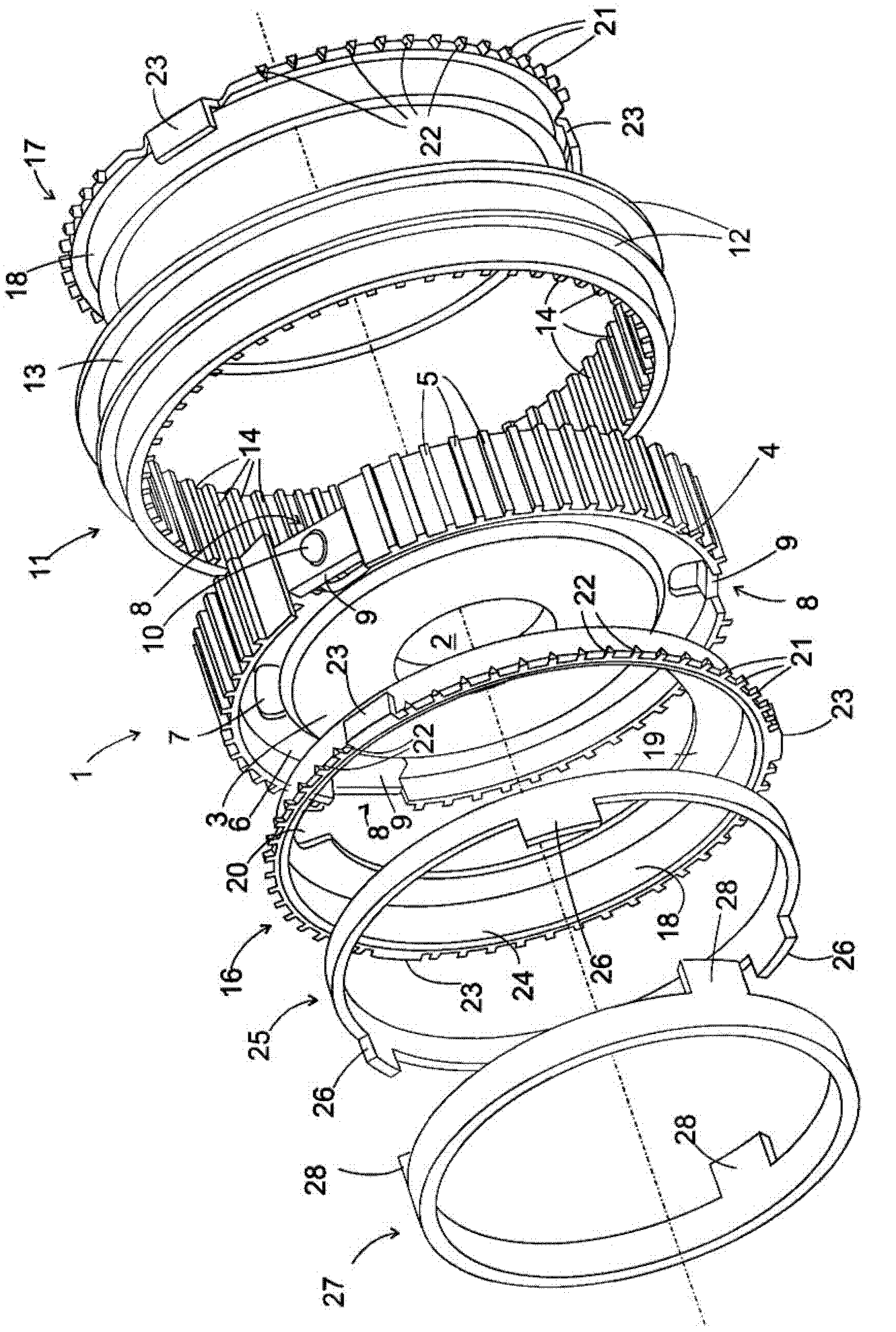

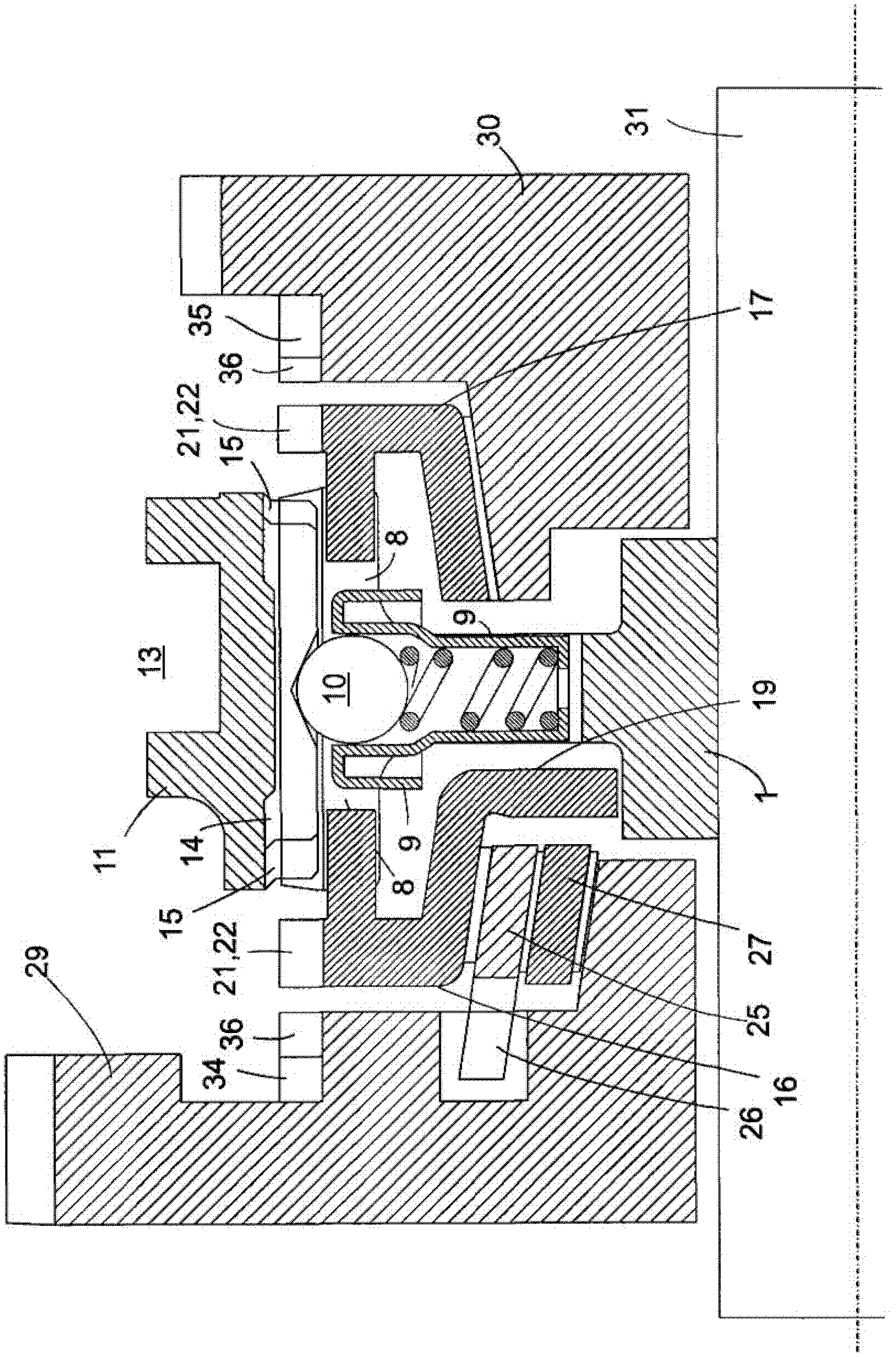

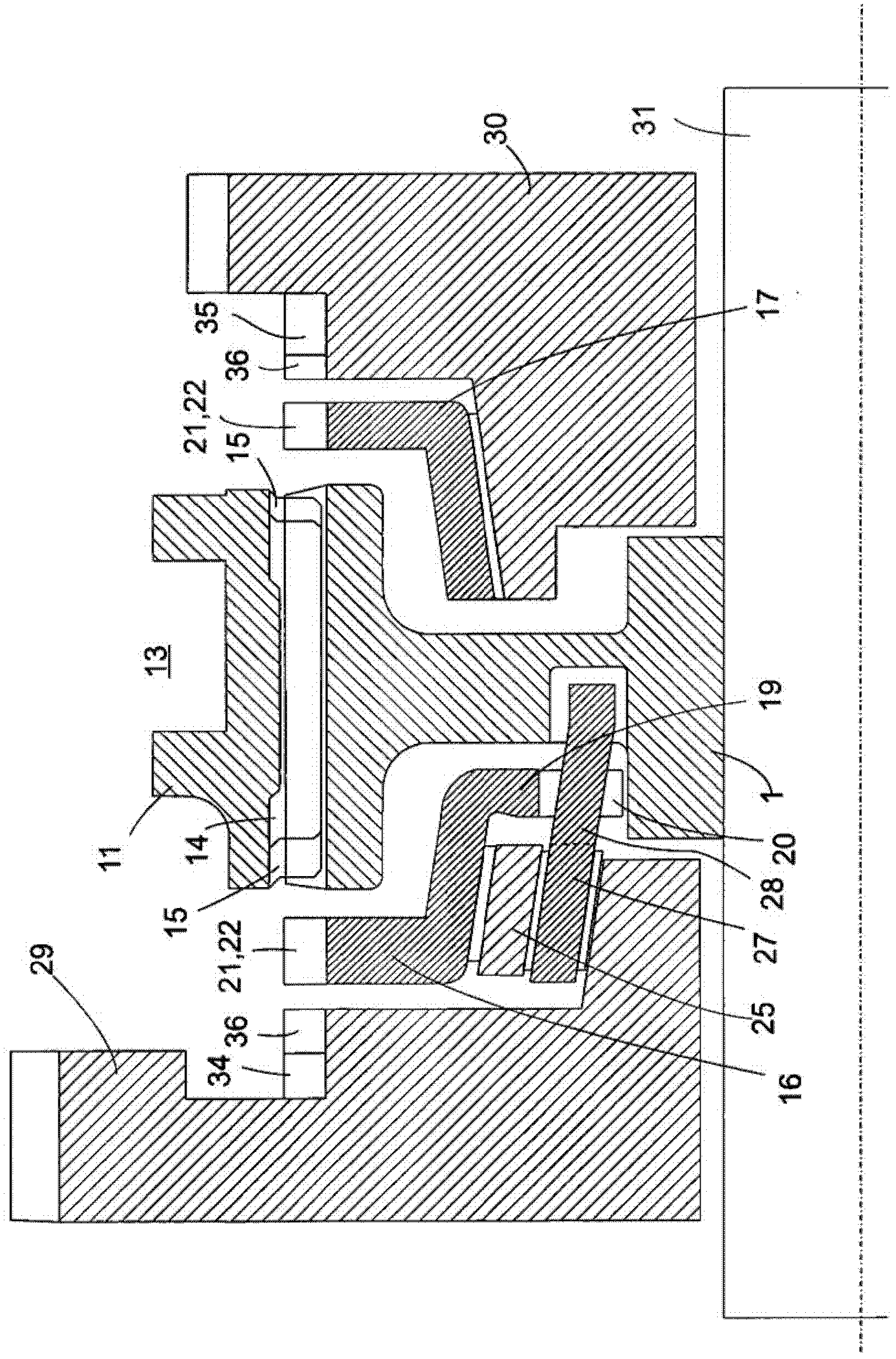

[0025] figure 1 is an exploded view of a double-acting synchronizer according to the present invention. The synchronizer comprises a hub 1 adapted to be non-rotatably splined to a shaft (not shown) extending through a central bore 2 of the hub 1 . The central part of the hub is in the form of a disc 3 and the tubular part 4 has engaging teeth 5 extending along the circumference of the disc 3 . Near the periphery of the disc 3 , an annular groove 6 is formed in the disc 3 and three shallow recesses 7 are formed in the groove 6 . exist figure 1 , only one of the three recesses 7 can be seen.

[0026] Three cutouts 8 are formed in the tubular portion 4 and extend well into the annular groove 6 of the disc 3 . Within the cutouts 8 are located booster blocks 9, each comprising a ball 10 biased radially outwards by a spring (not shown).

[0027] The tubular sleeve 11 has on its circumference two annular ribs 12 forming grooves 13 for engagement by a fork (not shown). The shift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com