Green vegetable reaping machine

A technology for green leafy vegetables and harvesters, which is applied in the direction of harvesters, agricultural machinery and implements, applications, etc., and can solve the problems of fragile green leafy vegetables, different growth heights, difficulty in mechanized harvesting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

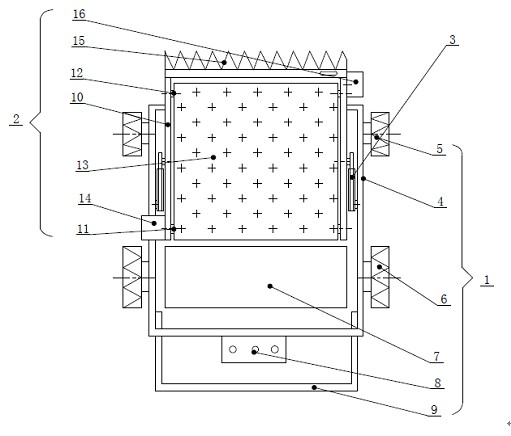

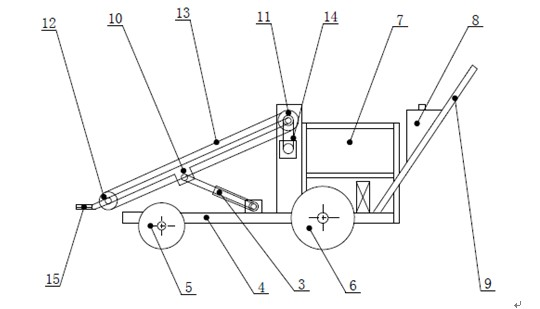

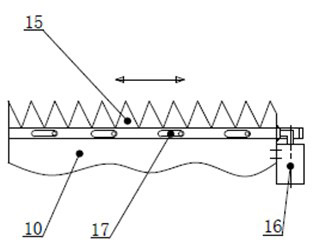

[0022] Such as figure 1 and figure 2 As shown, in this embodiment, the green leafy vegetable harvester includes: a frame assembly 1, a harvesting assembly 2 and an electric push rod 3, wherein: the non-cutting end of the harvesting assembly 2 is movably connected with the frame assembly 1, and the electric push rod One end of the bar 3 is movably connected with the frame assembly 1, and the other end of the electric push rod is movably linked with the harvesting assembly.

[0023] Frame assembly 1 comprises: vehicle frame 4, two front wheels 5, two rear whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com