Method for defoaming pipeline from mouth of gas well to separator by using solid defoamer device

A solid defoamer and separator technology, applied in wellbore/well parts, foam dispersion/prevention, production of fluid, etc., can solve the problems of increased maintenance cost, incomplete defoaming, complex equipment structure, etc., to save production The effect of maintenance cost, reduction of operation labor intensity and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, but protection scope of the present invention is not limited to the following:

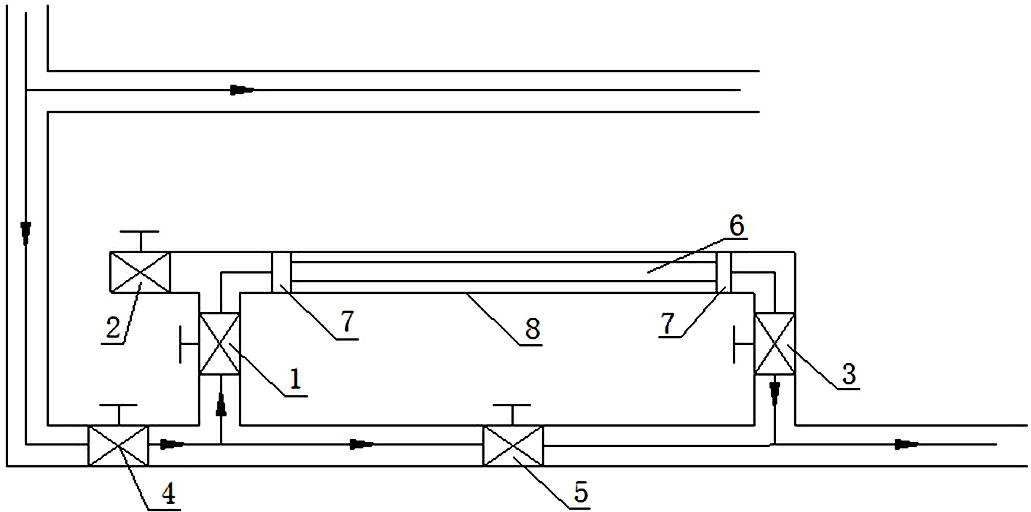

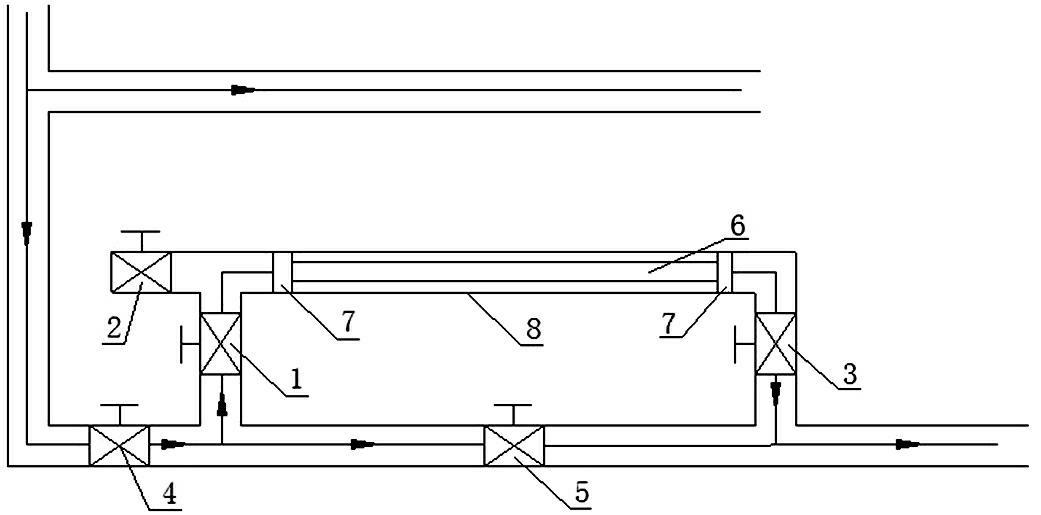

[0020] The solid defoamer device eliminates the foam in the gas well wellhead to the separator pipeline, such as figure 1 As shown, a solid defoamer device is installed in a bypass mode at a position about 30 meters away from the separator from the wellhead of the gas well to the gas transmission line of the separator. The solid defoamer device includes a main body 8, an inlet valve 1, and a packing valve 2 , Outlet valve 3, valve A4 is installed on the main line, valve B5 is installed on one end pipeline connected in parallel with the solid defoamer device, and the solid defoamer is placed in the main body 8 of the solid defoamer device through the filling valve 2.

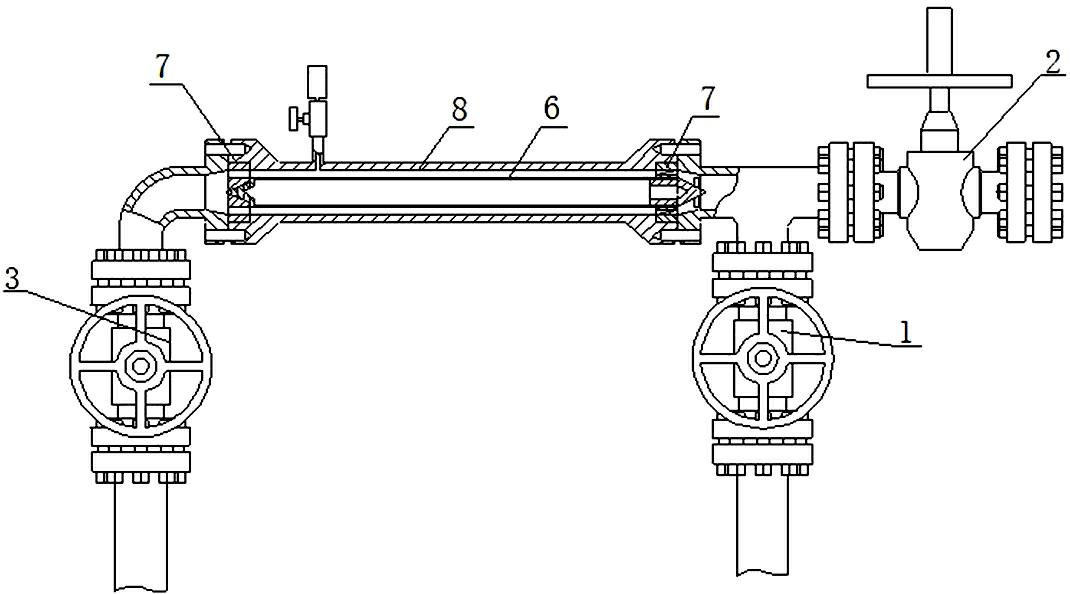

[0021] Such as figure 2 As shown, a fixed net 6 is installed in the main body 8 of the solid defoamer device, and the specially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com