Control method of numerical control spraying device for flat plate spraying

The technology of a spraying device and a control method is applied in the field of numerical control spraying device control, which can solve the problems of harming the health of sprayers, difficult to learn, and low spraying efficiency, so as to reduce the phenomenon of oil accumulation and oil consumption, reduce material waste, and reduce the spraying process. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

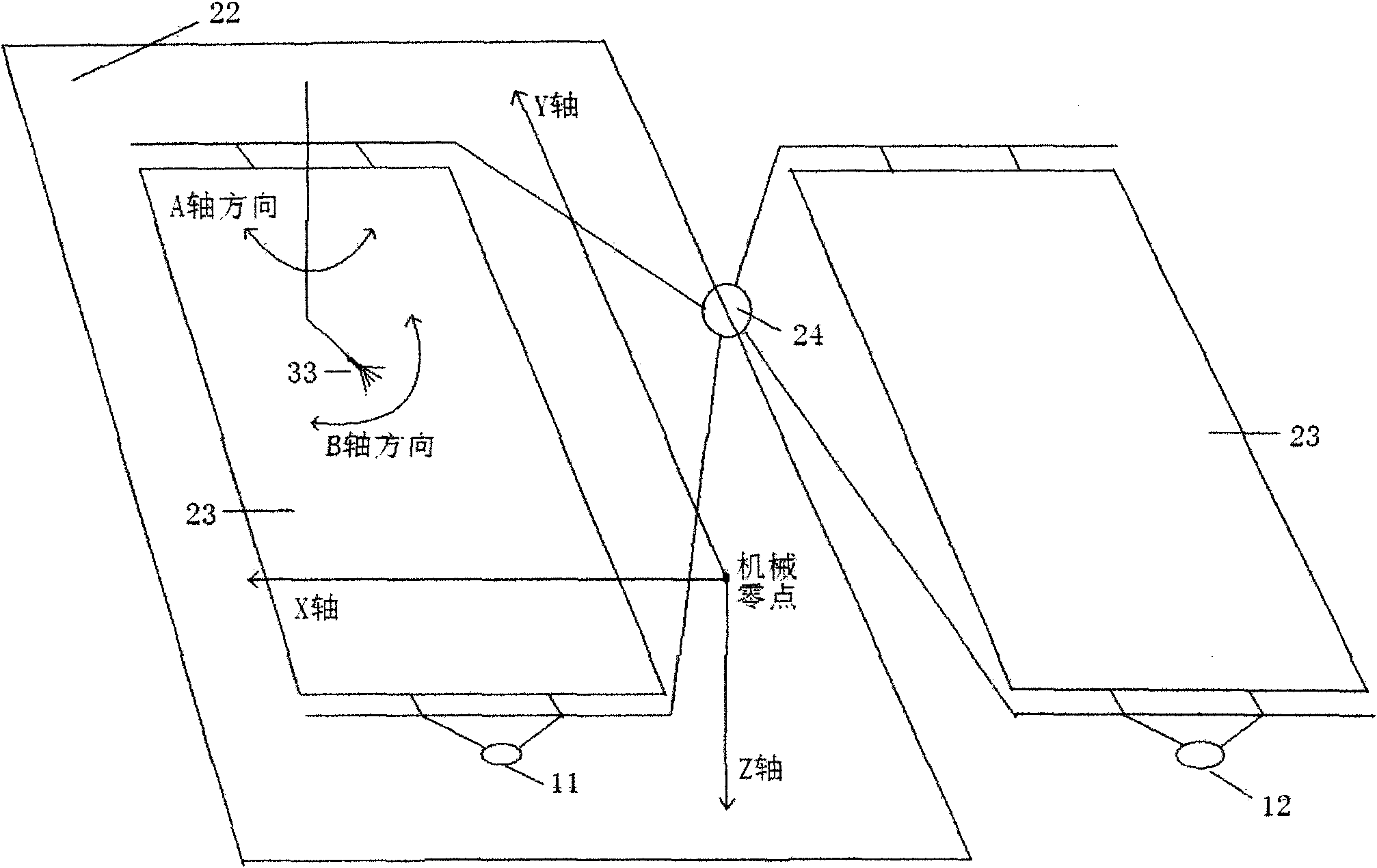

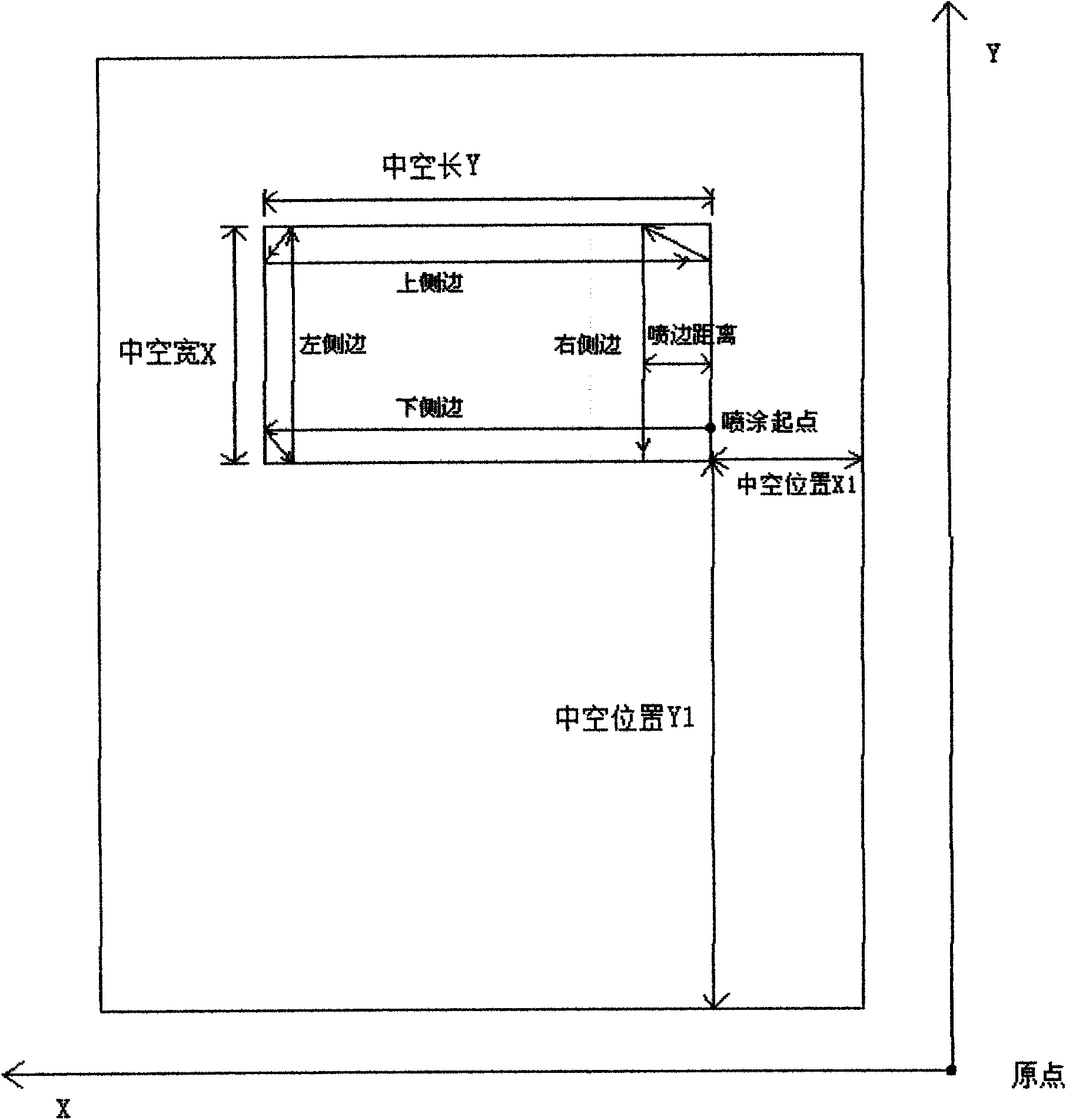

[0034] Spray the surface, edge, and inner edge of the plate: such as figure 1 , in the processing process, the operator inputs the overall width of the plate, the length of the plate, and the length and width of the inner side of the plate through the control input module, and the system information processing module generates process data and then converts it into processing data and outputs signals through the control output module Then control the five-axis spray gun control device, the revolution table mechanism 24, the A turning mechanism 11, and the B turning mechanism 12 to perform spraying processing in the spraying area 22 as required.

[0035] During the spraying process, you can set: the feeding distance and feeding direction of the spray gun 33 each time, the front and back of the plate 23, the height of the Z-axis of the spray gun, the horizontal rotation angle of the A-axis, the vertical rotation angle of the B-axis, and the enabling status of the spray gun 33.

...

Embodiment approach 2

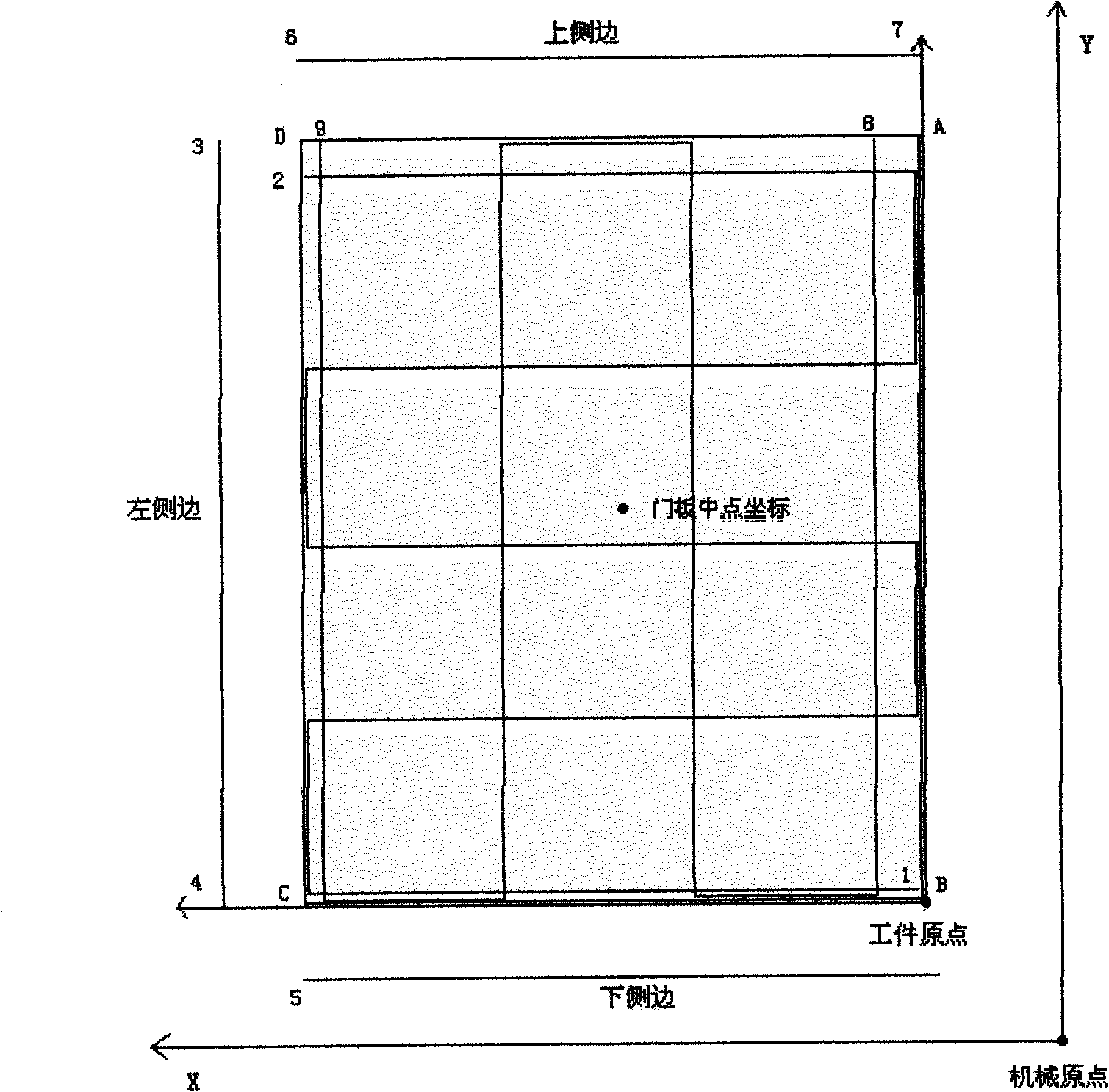

[0038] like image 3 , to determine the first point generated by each process in the continuous generation process to reduce the phenomenon of pulling the gun: in the process of processing, after the operator inputs the length and width of the plate through the control input part, the workpiece coordinates of the midpoint X and Y of the plate can be obtained value.

[0039] X coordinate of door panel midpoint = door panel width X÷2;

[0040] The Y coordinate of the middle point of the door panel = the length of the door panel Y÷2;

[0041] The first point of the next processing data generation process is determined according to the last point of the previous processing data generation process.

[0042] The end point (X1, Y1) of the last generated data, and the midpoint of the door panel (X0, Y0).

[0043] If (1) X1

[0044] The next generation process is, face X is fed in forward direction, face Y is fed in forward direction, the bottom side is measured, and the ...

Embodiment approach 3

[0066] Solve the accumulation of oil during the acceleration process: in the process of spraying, the spray gun is generally in high-speed motion, and the spray gun cannot always keep moving at a constant speed. Therefore, each straight line segment needs an acceleration and deceleration process when it moves. When spraying the straight line on the flat plate, the oil accumulation phenomenon will be caused due to the uneven speed of the acceleration section of the head and tail.

[0067] In order to solve this oil accumulation phenomenon, we widen left and right on both sides of the feeding direction of the flat spray surface, and widen left and right on both sides of the spray edge of the flat plate. The head and tail ends of the straight lines sprayed by each spray gun have all been lengthened like this. The long line along the head and tail is used for the acceleration and deceleration process. When the spray gun enters the plate to complete the acceleration process, it is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com