Spacecraft gridded composite bearing cylinder

A composite material and bearing tube technology, applied in the field of aerospace vehicles, can solve the problems of large bearing capacity and weak bearing capacity, and achieve the effect of improving bearing capacity, strong bearing capacity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

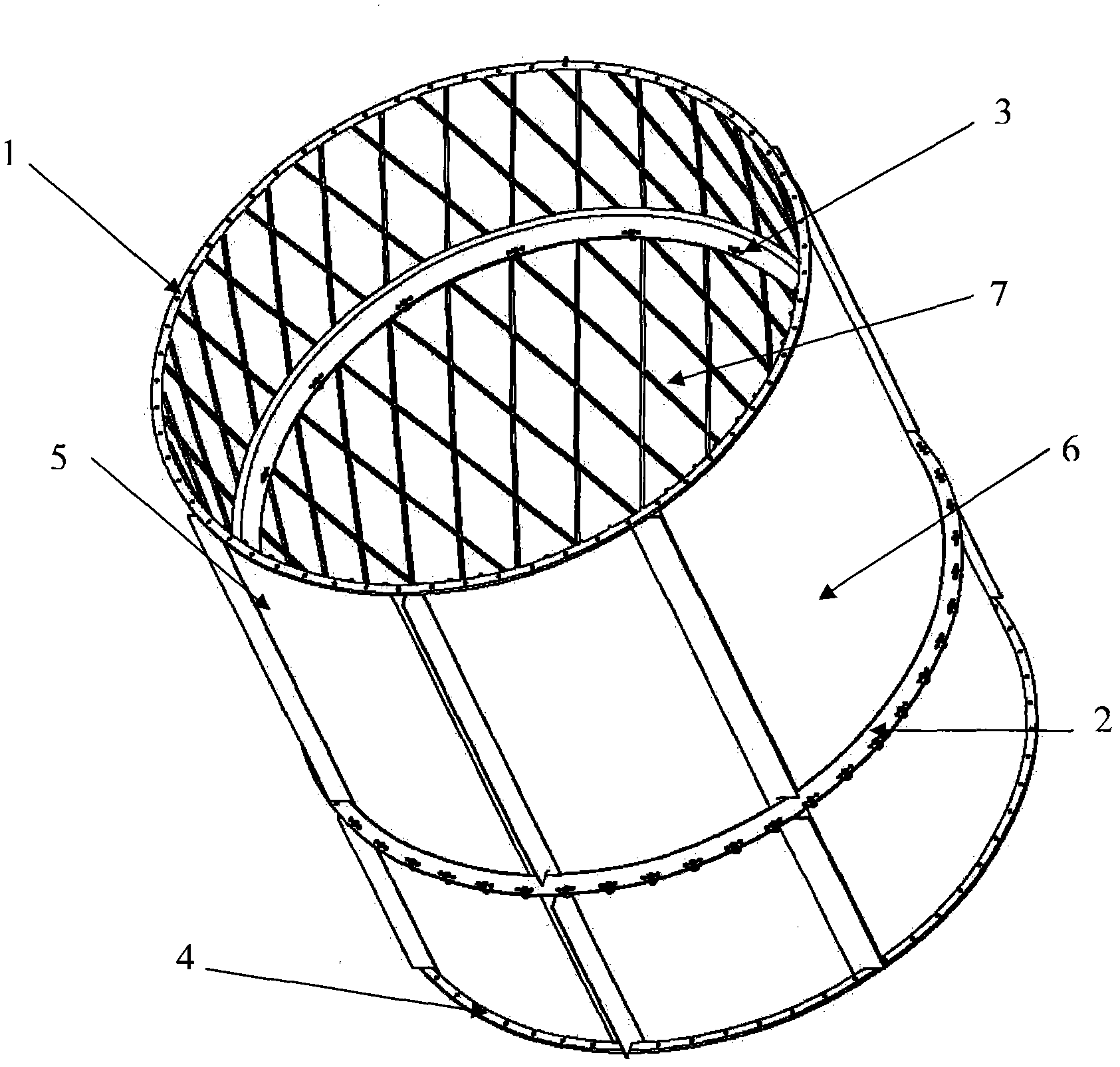

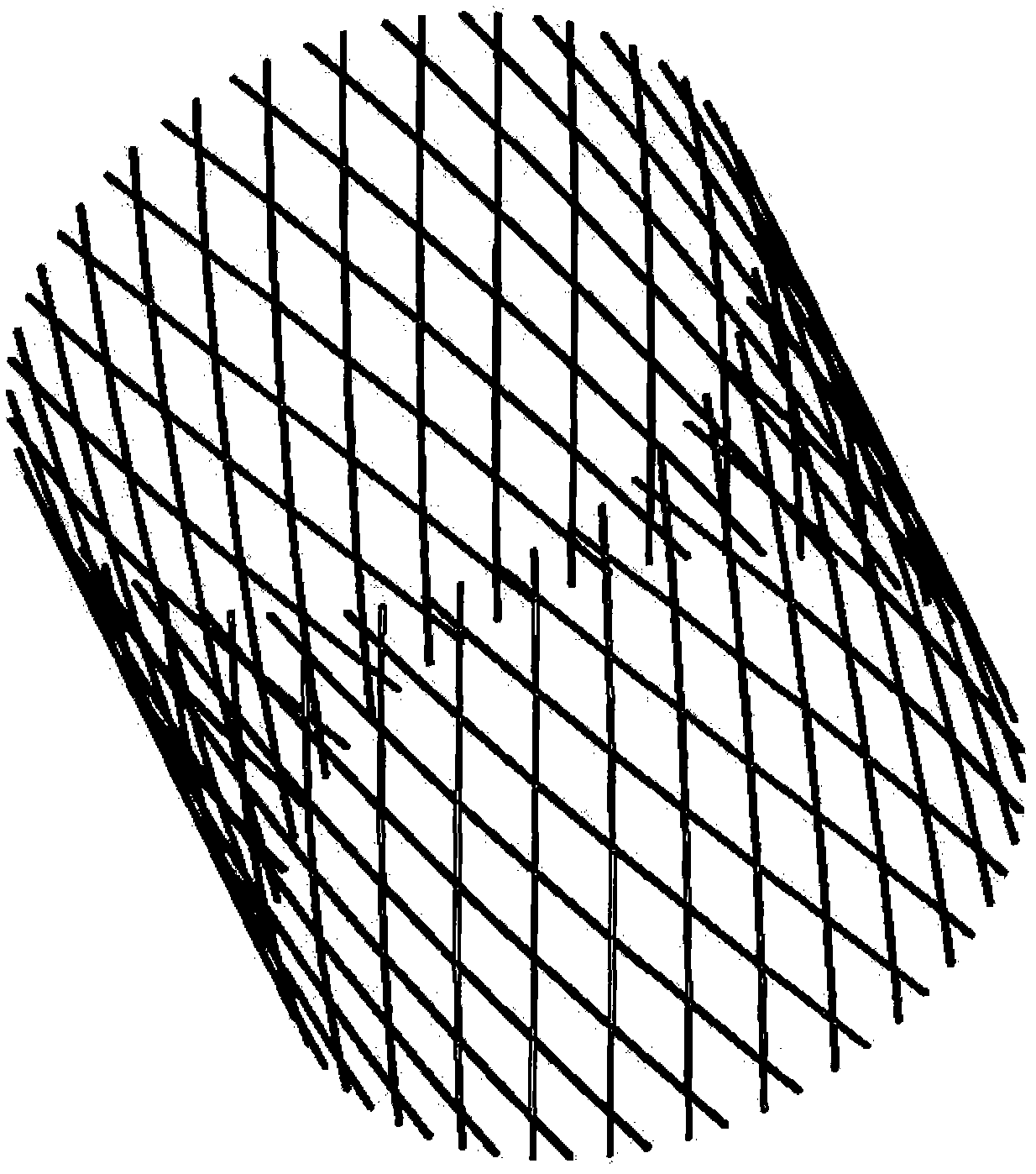

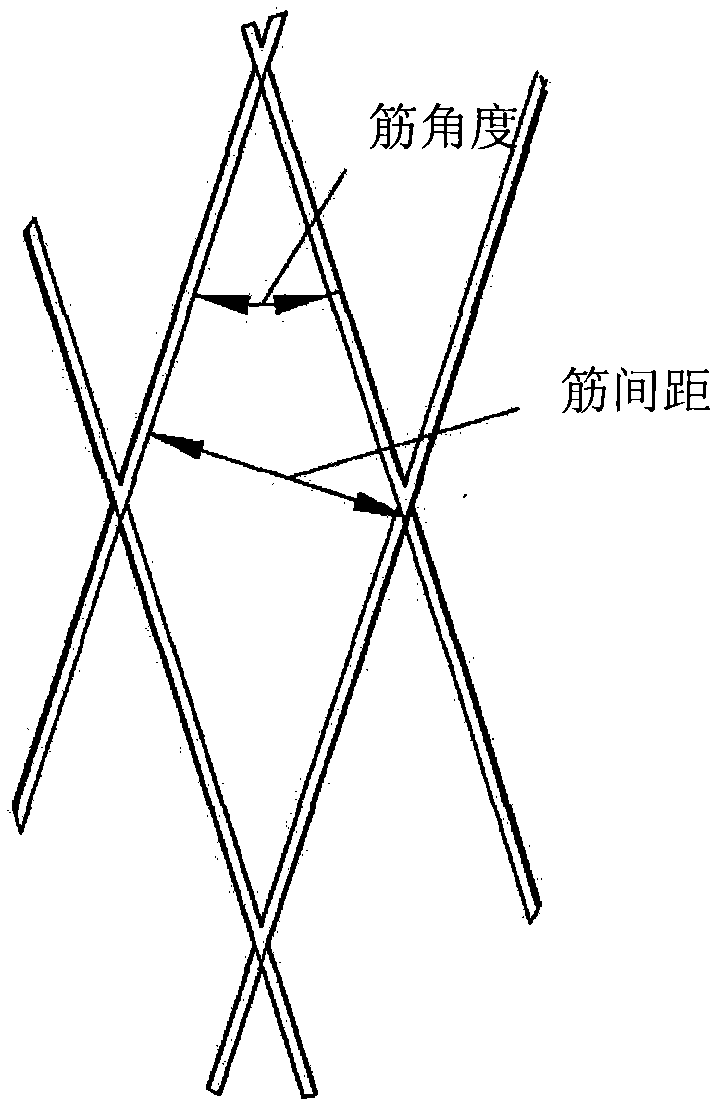

[0025] In one embodiment, the bearing cylinder of the present invention includes an upper end frame (1), a lower end frame (4), a skin (6) and grid tendons (7). Wherein, the outside of the grid ribs (7) is wrapped with a skin (6) to form a vertically transparent cylinder, the upper edge and lower edge of the cylinder respectively include an upper end frame (1) and a lower end frame (4). In this embodiment, the height of the formed bearing cylinder is between 1320mm and 1380mm, and the diameter of the cylinder is between 1100mm and 1250mm. This range of height and diameter is conducive to the installation of other components such as propellant tanks in spacecraft part. However, in other embodiments, the height and diameter of the bearing cylinder can also be adjusted accordingly as required.

[0026] The function and realization of each part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com