Real-time measurement device for temperature and current of through-flow bus of aluminum electrolysis cell

An aluminum electrolytic cell, real-time measurement technology, applied in the field of aluminum electrolytic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

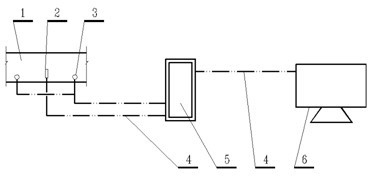

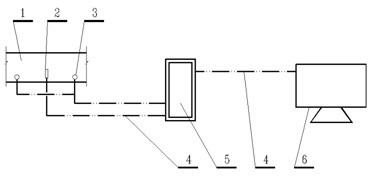

[0013] Such as figure 1 , the temperature measuring element 2 and the voltage probe 3 obtain the temperature and voltage difference information of the aluminum electrolytic cell bus 1, the measurement information is transmitted to the data conditioning collector 5 through the data connection line 4 for preprocessing, and then transmitted to the upper position through the data connection line 4 The analysis and display of the current is carried out in the industrial control machine 6 . The data conditioning collector 5 is integrated in the upper industrial control machine 6 .

Embodiment 2

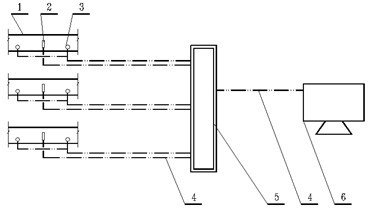

[0015] The temperature measuring element 2 and the voltage probe 3 can be arranged in groups to measure the temperature and voltage values of multiple busbars at the same time, and multiple groups of measurement information are transmitted to a data conditioning collector 5 through the data connection line 4, and the data conditioning collector 5 performs digital measurement. The unified conversion is then transmitted to the upper industrial control machine 6 through the data connection line 4 for analysis and display of multiple groups of currents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com